John Wood Power Direct Vent (Non-ENERGY STAR qualified models) User Manual

Page 31

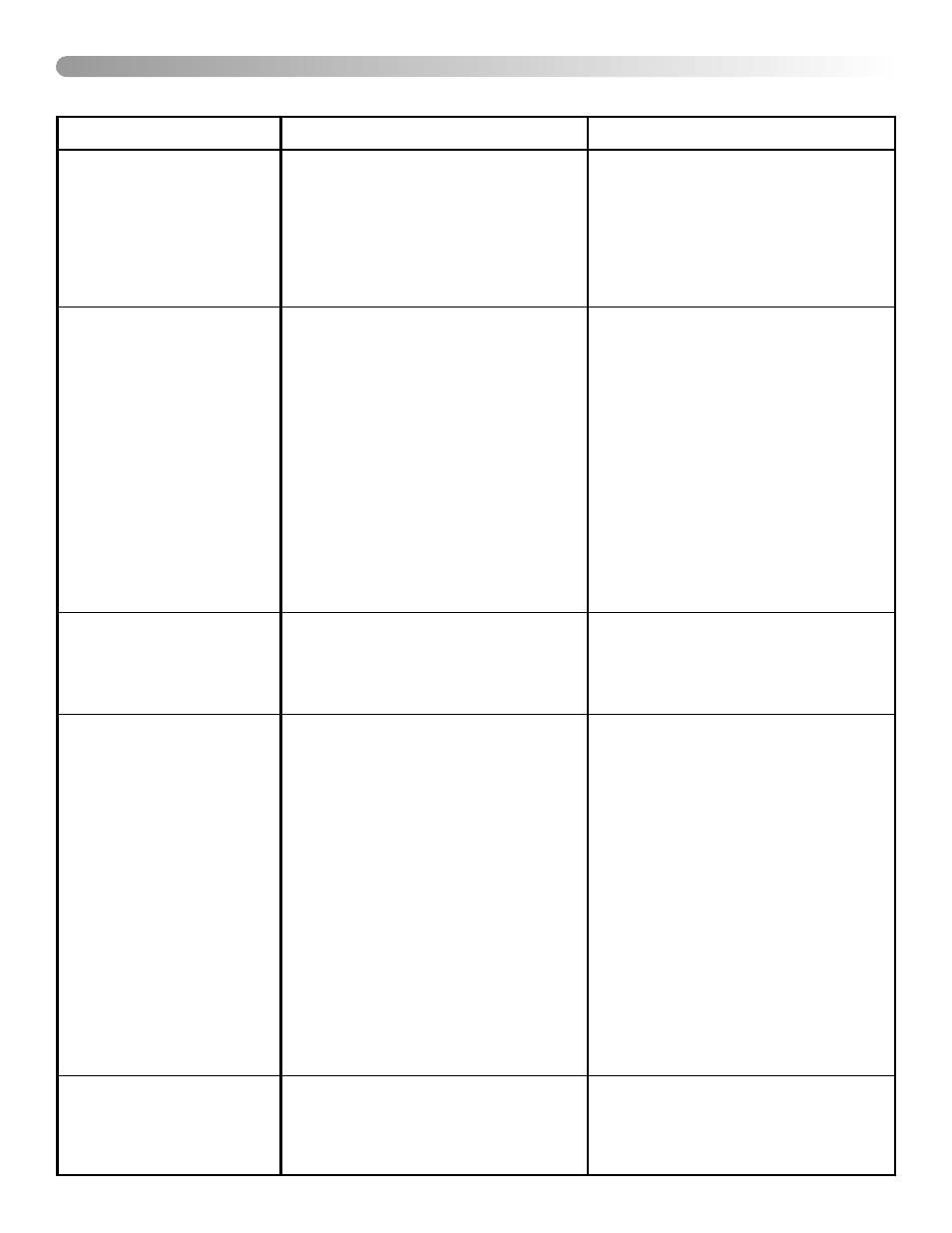

VIII) TROUBLESHOOTING GUIDE

Robertshaw 2000N WDER and White-Rodgers Intelli-Vent

TM

– 31 –

SYMPTOM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

BLOWER WILL NOT

START.

1. No Power to unit.

2. Thermostat setting too low.

3. Defective air pressure switch (must be

open at start-up before blower is ener-

gized).

4. Defective blower.

5. Disconnected or loose wire.

6. Control locked-out.

1. Plug in power cord, check fuses/supply

voltage.

2. Increase thermostat temperature set-

ting.

3. Replace air pressure switch.

4. Replace blower.

5. Repair/reconnect wires.

6. Reset – determine cause of lockout.

BLOWER RUNS

CONTINUOUSLY.

1. Air pressure switch not closing due to

insufficient draft - check for:

a) vent piping blocked,

b) piping length too long,

c) frozen vent termination,

d) clogged/dirty blower.

2. Disconnected, torn or blocked pres-

sure sensing tubing from air pressure

switch to blower housing.

3. Air pressure switch not closing due to

defective switch.

4. High limit switch open due to excessive

vent temperature or defective switch.

1. Determine cause of insufficient draft.

Check draft with manometer at pres-

sure switch (refer to Table 2 for mini-

mum acceptable draft settings).

a) remove blockage,

b) reduce vent length/increase vent

size,

c) clear termination of snow/ice,

d) clean blower wheel.

2. Reconnect or replace pressure sensing

tubing.

3. Replace defective pressure switch.

4. Determine cause of overheating check

for: overfiring, insufficient air supply,

high ambient air temperature (once

activated high limit must be replaced).

1. 120VAC polarity reversed at 120VAC

outlet receptacle.

2. Defective hot surface igniter.

3. Defective Control.

1. Reverse polarity at 120VAC outlet

receptacle.

2. Replace igniter (Check for 120VAC

across I1 & I2, Robertshaw only).

3. Replace control.

CONTROL LOCKED-OUT.

1. No gas supply.

2. Gas control switch in “OFF” position.

3. Insufficient gas supply.

4. Incorrect manifold gas pressure.

5. Incorrect gas type.

6. Defective igniter/loose or disconnected

wire.

7. Improperly positioned, dirty, or defec-

tive flame rod/loose or disconnected

wire.

8. Burner orifice clogged.

9. Blocked water heater flue.

10.Defective control.

1. Check/turn on gas supply.

2. Turn control switch to “ON” position

(Robertshaw only).

3. Ensure correct supply pressure for gas

type (Nat Gas 7.0 in. w.c. (1.74 kPa))

(Propane 11.0 in. w.c. (2.74 kPa)).

4. Check/adjust for correct manifold gas

pressure (NG 3.5 in. w.c.(0.87 kPa)),

(Propane 10.0 in. w.c. (2.49 kPa)).

5. Ensure correct gas type for water

heater model.

6. *Replace defective igniter/reconnect

wiring.

7. *Reposition, clean, or replace defective

flame rod/reconnect wiring.

8. Remove obstruction.

9 Remove blockage/clean flue.

10.Replace Control.

* See Figure 24 Parts Reference

CONTROL LOCKED-OUT.

*SOLID GREEN LED.

1. Internal control fault.

2. ECO failure – excessive water temper-

ature.

3. Excessive humidity/damp environ-

ment.

1. Replace control.

2. Replace control.

3. Allow control to dry.

HOT SURFACE IGNITER

NOT GLOWING

FOLLOWING WARM-UP

PERIOD.