Model ls, lc, lcp – Xylem LCP User Manual

Page 23

Installation, Operating and Maintenance Instruction

Model LS, LC, LCP

LS 100-english

page 21

Revision 02

Artikel No. 771073402

Issue

01/2010

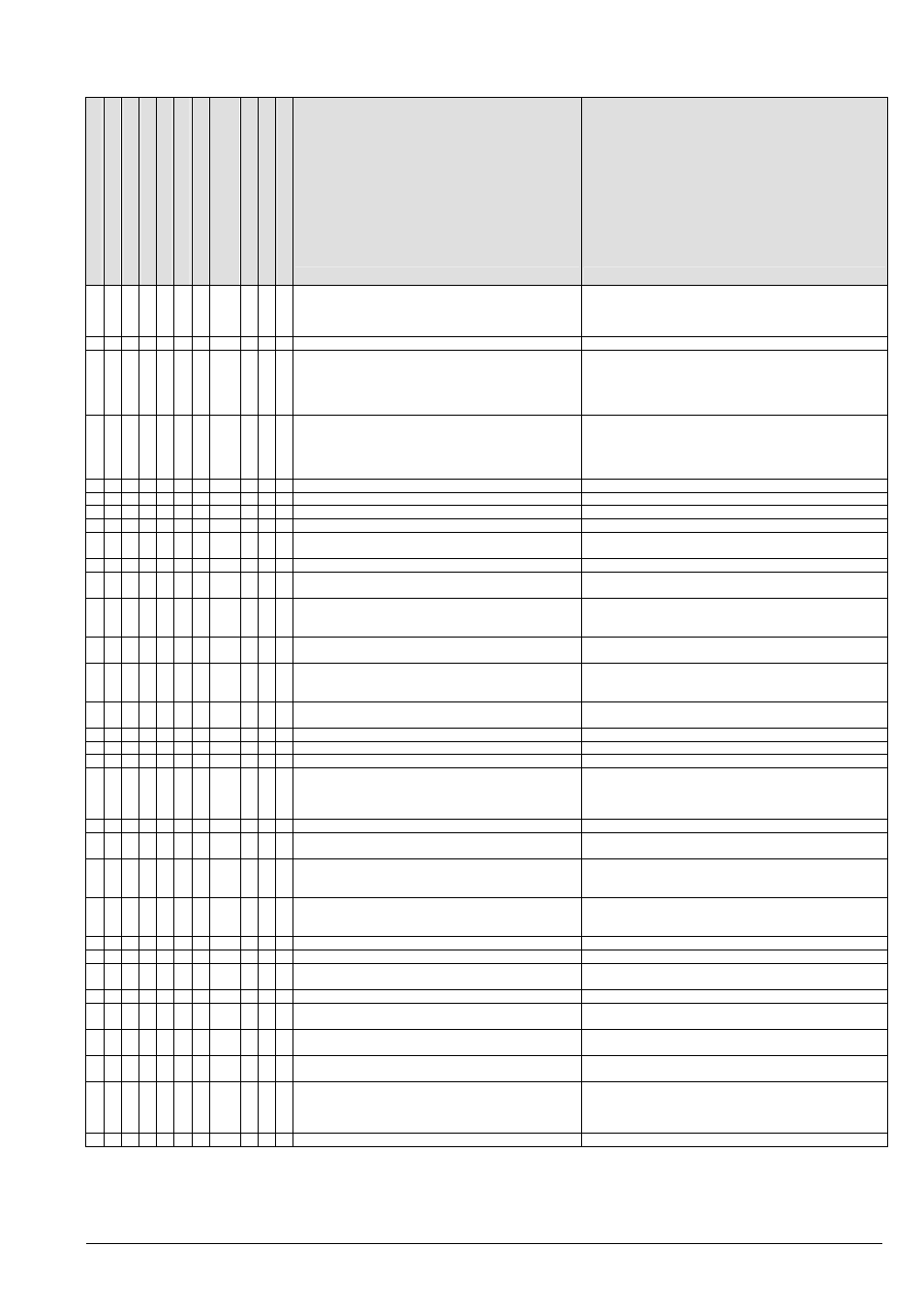

D

is

ch

ar

ge

to

o

lo

w

D

is

ch

ar

ge

s

to

ps

a

fte

r

a

tim

e

H

ea

d

to

o

lo

w

H

ea

d

to

o

hi

gh

D

riv

e

m

ec

ha

ni

sm

o

ve

rlo

ad

ed

P

um

p

no

t r

un

ni

ng

q

ui

et

ly

T

em

pe

ra

tu

re

in

p

um

p

to

o

hi

gh

T

em

pe

ra

tu

re

in

s

ha

ft

se

al

in

g

to

o

hi

gh

T

em

pe

ra

tu

re

a

t t

he

b

ea

rin

g

to

o

hi

gh

P

um

p

le

ak

in

g

Le

ak

ag

e

ra

te

a

t s

ha

ft

se

al

in

g

to

o

hi

gh

Cause

Solution

Back-pressure too high

check facility for pollution, open discharge valve

reduce resistance in discharge pipe (e.g. clean filter if

necessary)

use larger impeller (note available motor power)

Back-pressure too low, discharge too low

throttle discharge valve

Speed too high

reduce speed

compare speed of motor with specified pump speed (rating

plate)

when adjusting speed (frequency transformer) check reference

value setting

Speed too low

increase speed (check available motor power)

compare speed of motor with specified pump speed (rating

plate)

when adjusting speed (frequency transformer) check reference

value settings

Flow too little

increase min. flow (open discharge valve, bypass)

Flow too big

reduce flow (throttle discharge valve)

Impeller diameter too big

use smaller impeller

Impeller diameter too small

use larger impeller (check available motor power)

Pump and/or pipes not completely filled with liquid

fill

vent

Pump or suction/intake pipe blocked

clean

Air pocket in pipeline

vent

improve course of pipe

Suction height too big / NPSH of system too small

increase liquid level and admission pressure

reduce resistance in the intake/suction pipe (change course

and rated width, open shut-off valves, clean filters)

Air being sucked in

increase liquid level

check if suction pipe is vacuum-tight

Air being sucked in through shaft sealing

clean sealing pipe

increase sealing pressure

replace shaft sealing

Direction of rotation is wrong

swap over two phases of power supply (to be done by an

electrician)

Inner components suffering from wear

replace worn parts

Density and/or viscosity of liquid handled is too high

seek assistance

Stuffing box not straight

tighten evenly

Stuffing box is fastened too tight resp. shaft sealing is worn loosen stuffing box

replace packing and/or mechanical seal

check sealing, flushing and cooling pipes (pressure)

avoid dry running

Lines and roughness on shaft or shaft sleeve

replace parts

Unsuitable packing material

use suitable material (check shaft or shaft sleeve for damage

beforehand)

Deposits on mechanical seal

clean

replace mechanical seal if necessary

if necessary provide additional rinsing or quench

Impeller out of balance

remove blocks/deposits

replace impeller if broken or unevenly worn

check shafts to ensure that they are running true

Coupling not aligned

align pump unit better

Coupling distance too small

change

Forces in pipeline too high (pump unit under strain)

change (support pipes, use compensators, etc.)

is foundation plate/frame properly cast in place?

Too much, too little or the wrong type of lubricant

change

Electricity supply not right (2-phase running)

check voltage of all phases

check cable connections and fuses

Sealing insufficient

tighten screws

replace sealing

Bearing damaged

replace

check lubricant and bearing space for pollutants (rinse oil area)

Relief fittings insufficient

clean relief openings in impeller

replace worn parts (impeller, split rings)

adjust in line with the system pressure/intake pressure given on

ordering

System-related vibrations (resonance)

seek assistance