Xylem WMP101-Series ELECTROMAGNETIC FLOWMETERS User Manual

Page 4

FLOW RANGE, INSTALLATION

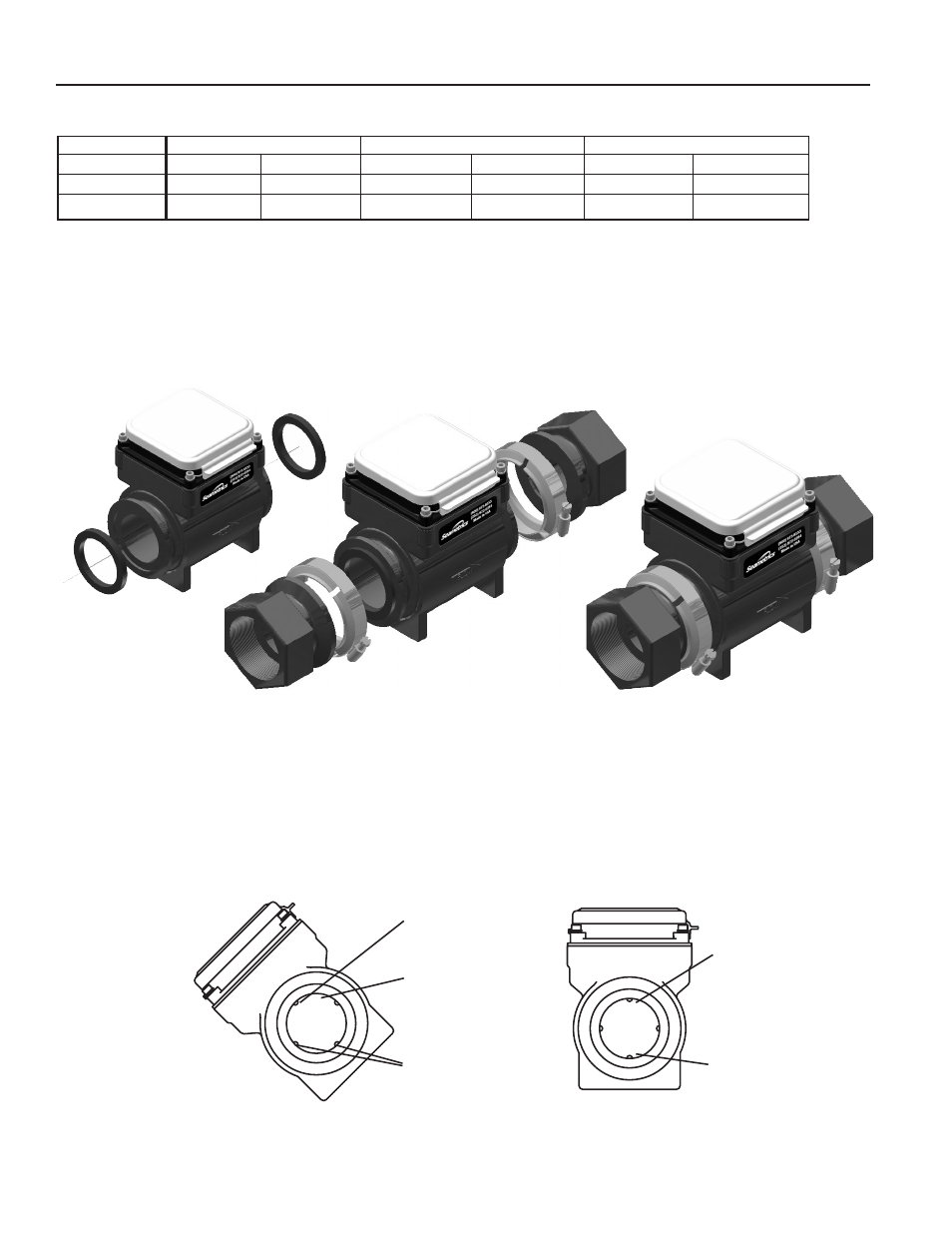

Step 1.

Position gasket

at either end

Step 2.

Place adapter

against gasket,

open screw clamps

to clear flanges

Step 3.

Place screw-clamps

over both adapter

and meter flanges

and tighten screws

INSTALLATION

Piping Conditions.

Installing the meter with a length of

straight pipe at least two times the diameter upstream and

one diameters downstream is highly recommended. Some

piping conditions require more than this. See chart for rec-

ommendations.

End Connections.

The meter comes with Banjo™ union-type

flange connections for ease in servicing the meter. To con-

nect these to piping ends, a variety of kits are available from

any Banjo dealer or from Seametrics.

Follow the diagram below to make the connections.

Position.

This is an all position meter which can be installed either vertically or horizontally, register up, down or angled. How-

ever, entrained air or solids may make some positions preferable to others. See the position diagram for guidance.

Less Ideal:

Air bubbles and sediment on the

electrodes can affect accuracy

Intermittent air

bubbles

pass over

electrode

Possible

sediment

build-up

Recommended:

May prevent sediment

or bubble problems

Electrode

moved from

top by rotating

meter

Intermittent air

bubbles

miss electrode

Electrodes free

from sediment

build-up

WMP

WMP

3

FLOW RANGE

NOTE:

Above installation instructions are for WMP101/104-200 (2”) and WMP101/104-300 (3”) only. The WMP101/104-

100 (1”) is provided with intergrated NPT female threaded ends.

1” 2” 3”

Gal/Min

Liter/Sec

Gal/Min

Liter/Sec Gal/Min Liter/Sec

2.3

.145

6 .38 14 .88

110

6.94

300 18.9 670 42.3

Minimum

Maximum