En 8. troubleshooting – Xylem Sphere and Block Units User Manual

Page 13

en

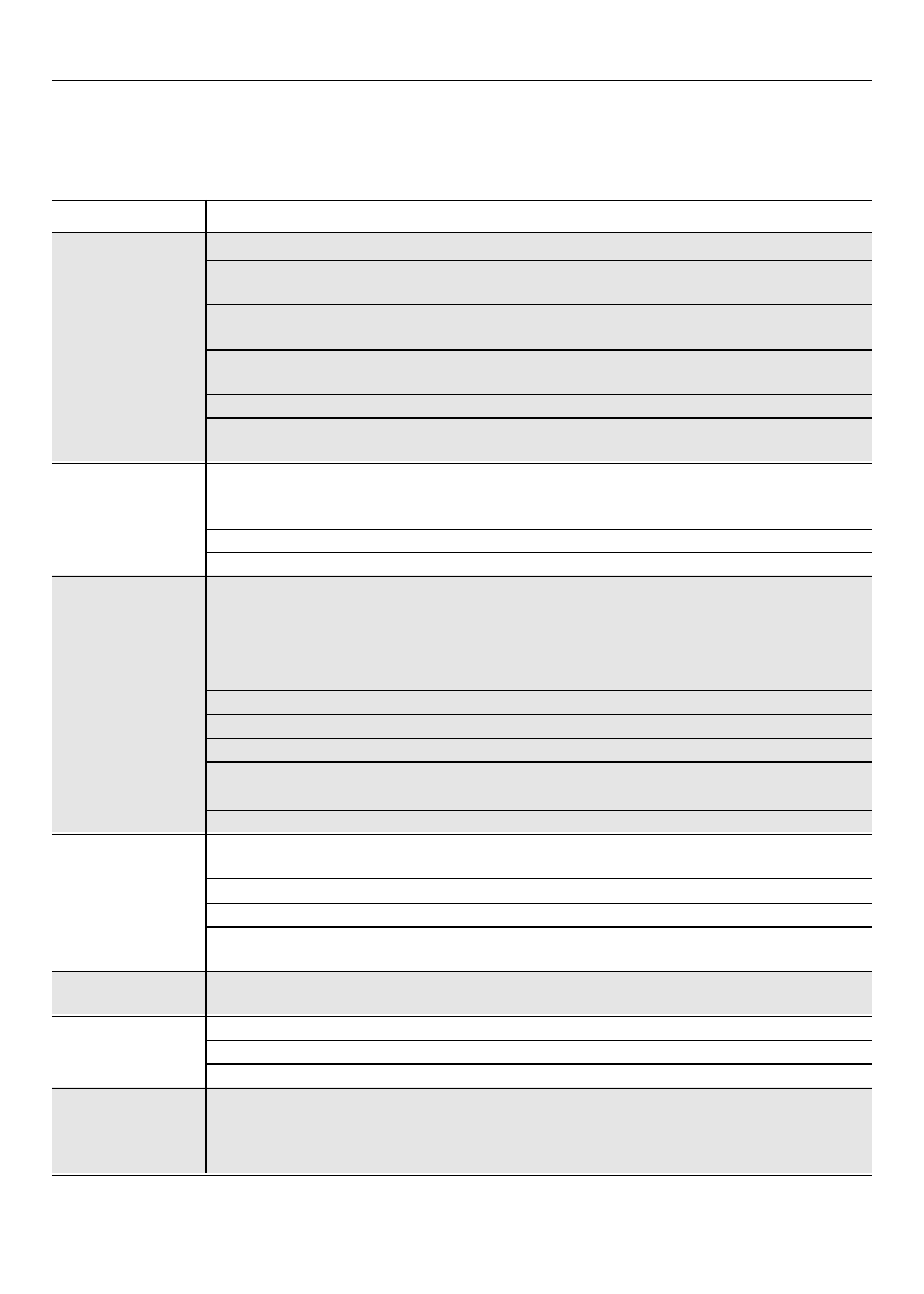

8. Troubleshooting

If the malfunction is not included in the chart below or is marked by an asterisk, please contact a service

centre near you.

PROBLEM

PROBABLE CAUSE

NOTES

PUMP DELIVERS

No power supply

NO WATER,

Overload protection

Automatic resetting after

MOTOR DOES

tripped

cooling (single-phase model)

NOT START

Tripping of automatic switch or

Reset the switch. If it trips again

differential switch

call a qualified electrician

Impeller jammed

Foreign bodies block the

impeller

Faulty capacitor

Replace the capacitor.

Minimum pressure setting

Reset the pressure switch

too low

PUMP DELIVERS

Water level too low and foot

Attention: mechanical seal or

NO WATER,

valve out of water

impeller could be

MOTOR STARTS

damaged

Pump not full with liquid or leaks

Same as above

Non-return valve clogged

PUMP GIVES

Suction lift exceeds pump lift

Reduce suction lift.

INSUFFICIENT

capacity on friction losses

Replace suction pipe with one

WATER OR

too high on suction side

of larger diameter.

PRESSURE

Reduce elbows.

Remove deposits.

Pump or pipes clogged

Clean or unclog

Impeller or volute worn

Poor voltage supply

Air inside suction piping

Wrong pressure switch setting

Reset the pressure switch

Incorret pump choice

PUMP STARTS

Tank air-preloading insufficient

Check pre-loading pressure

TOO FREQUENTLY

or excessive

Diaphragm broken in the tank

Wrong pressure switch setting

Reset the pressure switch

Water leaks through non return

valve or pipes

PUMP DOES

Maximum pressure setting

Reset the pressure switch

NOT STOP

too high

NOISY

Suction lift too high

OPERATION

Pump runs beyond rated delivery

Worn bearings

WATER LEAKS

Mechanical seal worn or

BETWEEN PUMP

damaged

SUPPORT

AND MOTOR

13