Lowara uk limited – Xylem Resvari Booster Set Variable Speed User Manual

Page 4

4

Maintenance

Routine check (6 monthly intervals)

1. Check the pump produces the correct pressure.

2. Check that the pump operates without undue noise or vibration.

3. Check the break tank is clean and that the correct water level has been maintained.

4. Check that all screws are tight on electrical components.

5. Check that the earth connections are tight and making good contact.

6. Check that the gas pre charge is at the correct pressure, this should be done by isolating the vessel from

the system and draining water out of the vessel via the isolation valve drain point.

once the water has been discharged, a tyre gauge can be connected to the pre charge valve to display the

vessel pre charge pressure. Recharge as necessary with Nitrogen or dry air.

Any other expansion vessels connected to the system can be checked in the same manner.

General fault finding guide

Lowara UK Limited

Millwey Rise Industrial Estate, Axminster, Devon EX13 5HU - UK

Tel: 01297 630230 Fax: 01297 630270

e-mail: [email protected]

http://www.lowara.co.uk http://completewatersystems.com

Lowara is a trademark of Xylem Inc. or one of its subsidiaries. © 2011 Xylem, Inc.

Lowara reserve the right to make modifications without prior notice.

cod. UKLIT0092 P05/12

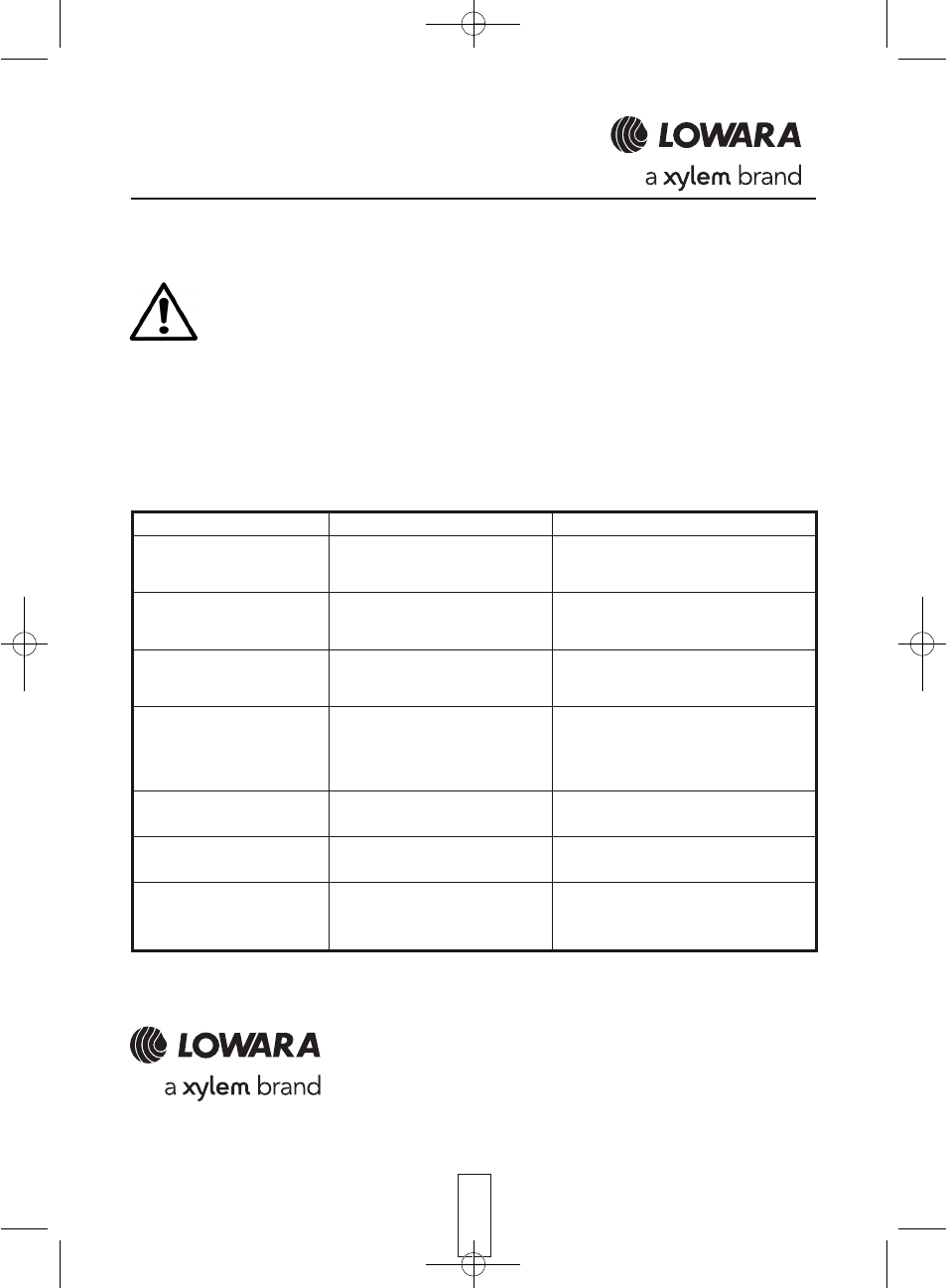

Fault

Possible Cause

Remedy

Pump fails to start

Power supply failure

Isolator fuse blown/MCB tripped

Reinstate incoming power supply

Replace fuse/reset MCB

Pump fails to stop

Set point set too high

System pressure low due to large

leak in system

Lower set point

Switch unit off until leak is repaired

Pump switches on and off

quickly

Air in system

Vessel pre-charge incorrect

Purge air from pumps and pipework

Check vessel pre-charge and Charge as

necessary with Nitrogen or dry air

Pump runs but will not

make pressure

Pump air locked

Commissioning valve left open

Passing too much water

Vent pump

Check commissioning valves are in

correct position.

Check system for leaks

Pump overheating

Pump partially seized

Remove pump and check for sediment

build up or foreign objects

Break tank overflowing

Leaking ball valve

Non-return valve letting by

Replace ball valve seal

Replace/clean non-return valve

Pump stops and pressure

drops immediately

Non-return valve letting by

Vessel pre-charge incorrect

Replace non-return valve

Check vessel pre-charge and Charge as

necessary with Nitrogen or dry air

resvari vs booster set o and m instructions:Layout 1

09/05/2012

16:18

Page 4