Reassembly, Seal assembly – Xylem P2001406B Series e-1510 Centrifugal Pumps User Manual

Page 32

Balancing

It is recommended that impellers trimmed more than 5% in diameter be rebalanced per

ISO 1940 grade G6.3.

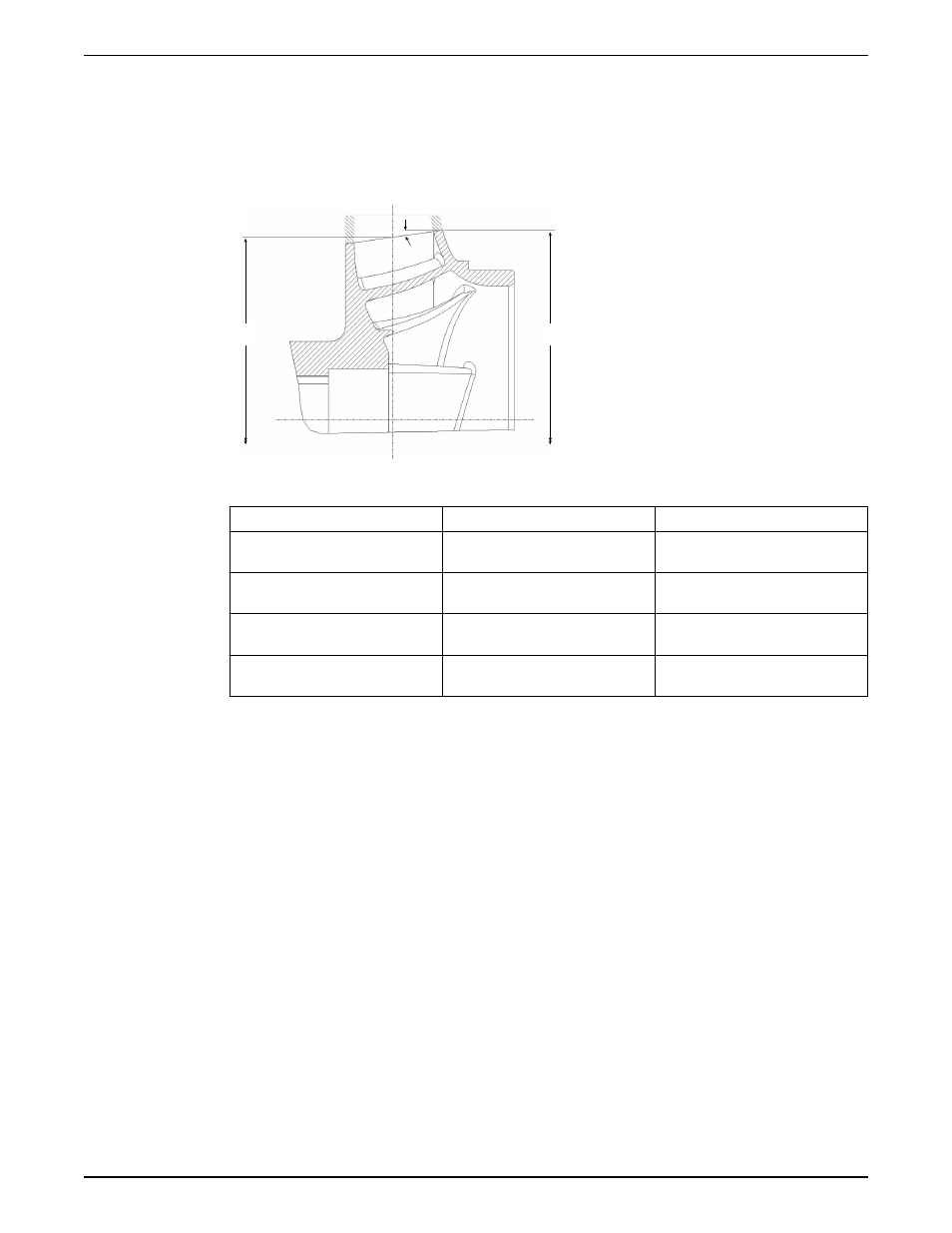

e-1510–4AD angle cut guidelines

Model e-1510-4AD pump impellers must be angle cut at reduced diameters according to

the following information.

ØA

ØB

C

Figure 6: 4AD impeller trim — 0.125 in. (3.17 mm) increments

A

B

C

Hydraulic diameter, nominal, as

shown on selection curves

Diameter at impeller inlet side

shroud

Trim angle

From maximum diameter 7 in.

(177.8 mm) to 6.125 in. (155.6 mm)

Use diameter from selection curves

0 degrees, no angle

6, 5.875, 5.75, 5.625 in. (162.4 to

142.9 mm)

B = A plus 0.250 in. (6.35 mm)

8 degrees

5.5, 5.375, 5.25, 5.125, minimum 5

in. (139.7 to 127.0 mm)

B = A plus 0.375 in. (9.53 mm)

8 degrees

Reassembly

Seal assembly

Assemble the standard mechanical seal (e-1510 and e-1510-F)

1. Lubricate the shaft sleeve and coverplate seal cavity with soapy water.

Do not use a petroleum lubricant.

2. Install a new insert gasket.

3. Install a new seal insert and make sure that the indentation is against the insert gasket.

4. Slide a new rotating seal assembly onto the shaft sleeve.

5. Push the top of the compression ring with a screwdriver until the seal is tight against

the seal insert.

6. Install the seal spring and point the narrow end toward the seal.

Maintenance

30

Series e-1510 Installation, Operation, and Maintenance Manual