Xylem IM 16 Seal-less Centrifugal Canned Motor Pumps For Instant Hot Water Recirculating System (obsolete) User Manual

Page 4

4

UltraCirc Models

The UC and UCT-303/353 models incorporate a shut off valve and check valve into the brass pump

housing eliminating the need to install these components. Models with a 01 designation have a

built-in air bleeder valve. These models are supplied with 1/2” (5/8”) union fittings. These fittings

should be removed from the pump housing before soldering to avoid damaging the internal valves.

For SM(T) - 909/959 Models

This unit may be installed into the pipe system without disassembling the pump. However, it is

recommended that the motor section be disassembled from the pump housing by removing the two

pump housing screws so that the system may be flushed as noted in paragraph 9.

For SM(T) - 909/959 Models

This unit may be installed into the pipe system without disassembling the pump. However, it is

recommended that the motor section be disassembled from the pump housing by removing the two

pump housing screws so that the system may be flushed as noted in paragraph 9.

Shut-Off Valve (allows isolation of water in the tank in the event of pump servicing). Hose Bib/

Connection (allows venting of air from system at start-up). Auto Air Vent (allows continuous venting

of air bubbles that intrude into all hot water circulating systems during operation).

8. Close the shut-off valve on the inlet side of the pump and turn the water supply back on.

9. Flush system of debris. Before reattaching the pump motor, open the

shut-off valve on the inlet side of the pump housing and let water flow

through the housing. Use a bucket to catch the water. Let the water run

long enough to clear all sand, solder pellets, plumbers tape flakes, etc.

from the lines. Close the inlet shut-off valve when finished.

10. Connect the pump motor to the housing. Make sure the rubber

o-ring is in place in the housing and the screw ring is securely hand

tightened (for 303/353 models) or that the top housing screws

are firmly in place and tightened (909/959 models). Open the shut-off

valve or valves and let the water flood the pump housing.

11. Purge air from the supply line. Turn on the faucet/taps or shower

farthest from the water heater. Open the line until you get a good,

steady stream of water without sputter or evidence of air.

12. Purge air from the return line. Connect the pump to the electrical supply. With the pump running,

open the hose bib/connection and let water run until the pump is running quietly and there is no

sputtering or other evidence of air coming from the hose bib. Close the hose bib. UC/UCT-303-01

models have a built-in air bleeder valve, use this valve to purge the return line of air. Your system is

now in operation. Allow a few minutes for instant hot water to recirculate to all of your faucet/taps.

SM-909/1212

SAFETY PRECAUTION: Remove the handle from the hose bib(s)/connection(s) to prevent a small child

from mistaking it for a water faucet/tap. Insulating both the hot water supply and recirculation lines is

strongly recommended.

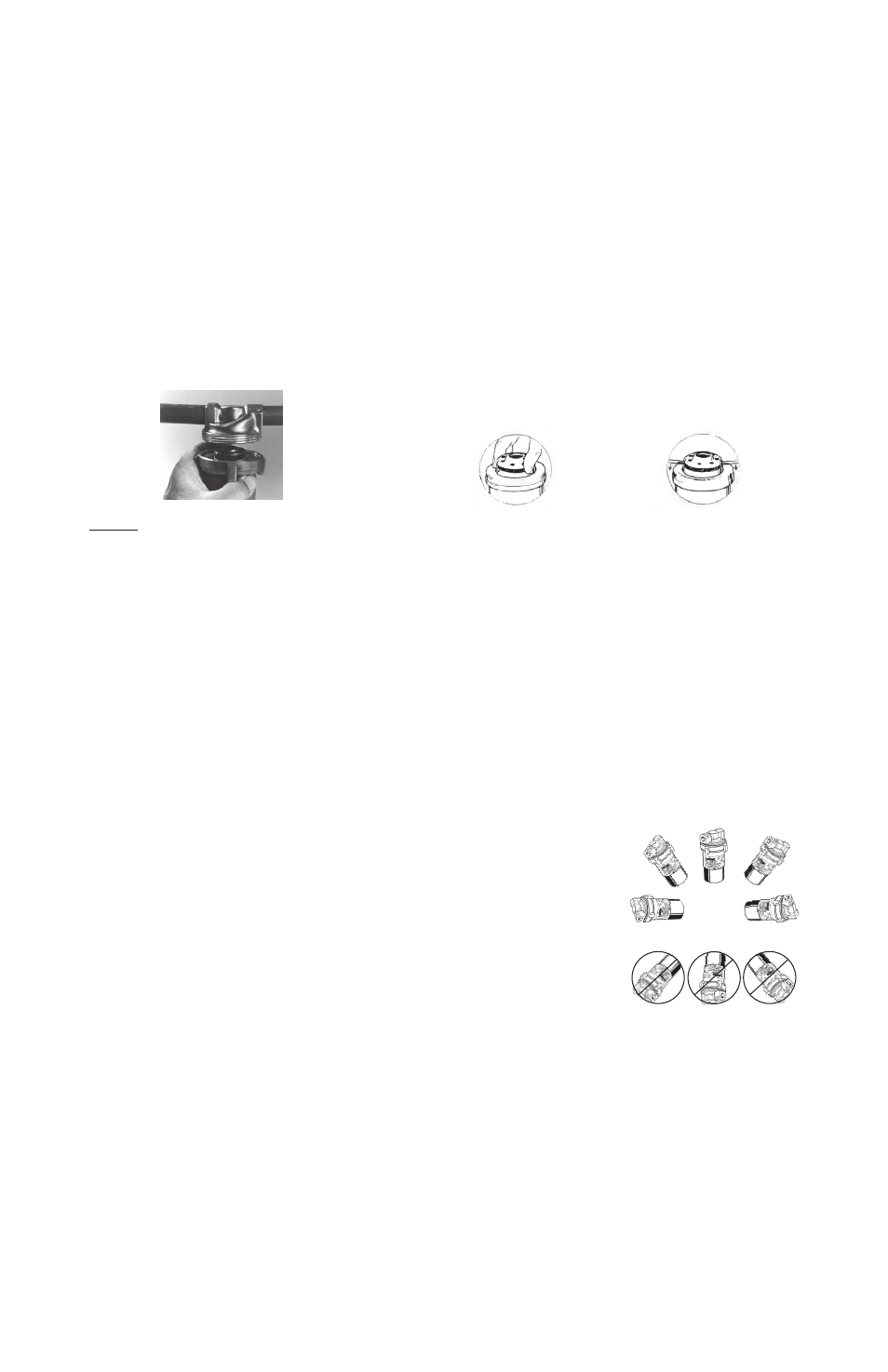

Fig. 5

303/353 Models - Rotor/Impeller Installation: To remove

the rotor unit, grasp the top of the unit and gently pull

straight up. Do not pull up on one side only or push the

rotor sideways. If the rotor sits too tightly, carefully lever

it off with a screwdriver on each side of the rotor. When

re-installing the rotor, use enough force to hear the rotor

“click” on to the ceramic bearing and spin the rotor with

your fingers to insure that it turns freely.

Fig. 4

Remove the motor unit and o-ring from the pump

housing into the plumbing line. Do not sweat the

housing into the plumbing line with the motor

or o-ring attached. Arrows on the pump housing

indicate the direction of water flow.

Caution: Only hand tighten the screw ring. Do

not over tighten! Do not use plumbers putty on

the screw ring.

Remove the Rotor/ Impeller

by using forefinger and

thumb and pulling upward.

Or, if the Rotor/Impeller cannot

be removed using forefinger and

thumb, carefully lever off evenly

with two screwdrivers.

Correct Installation

Improper Installation

Do NOT mount in these

orientations