Xylem IM 16 Seal-less Centrifugal Canned Motor Pumps For Instant Hot Water Recirculating System (obsolete) User Manual

Page 3

3

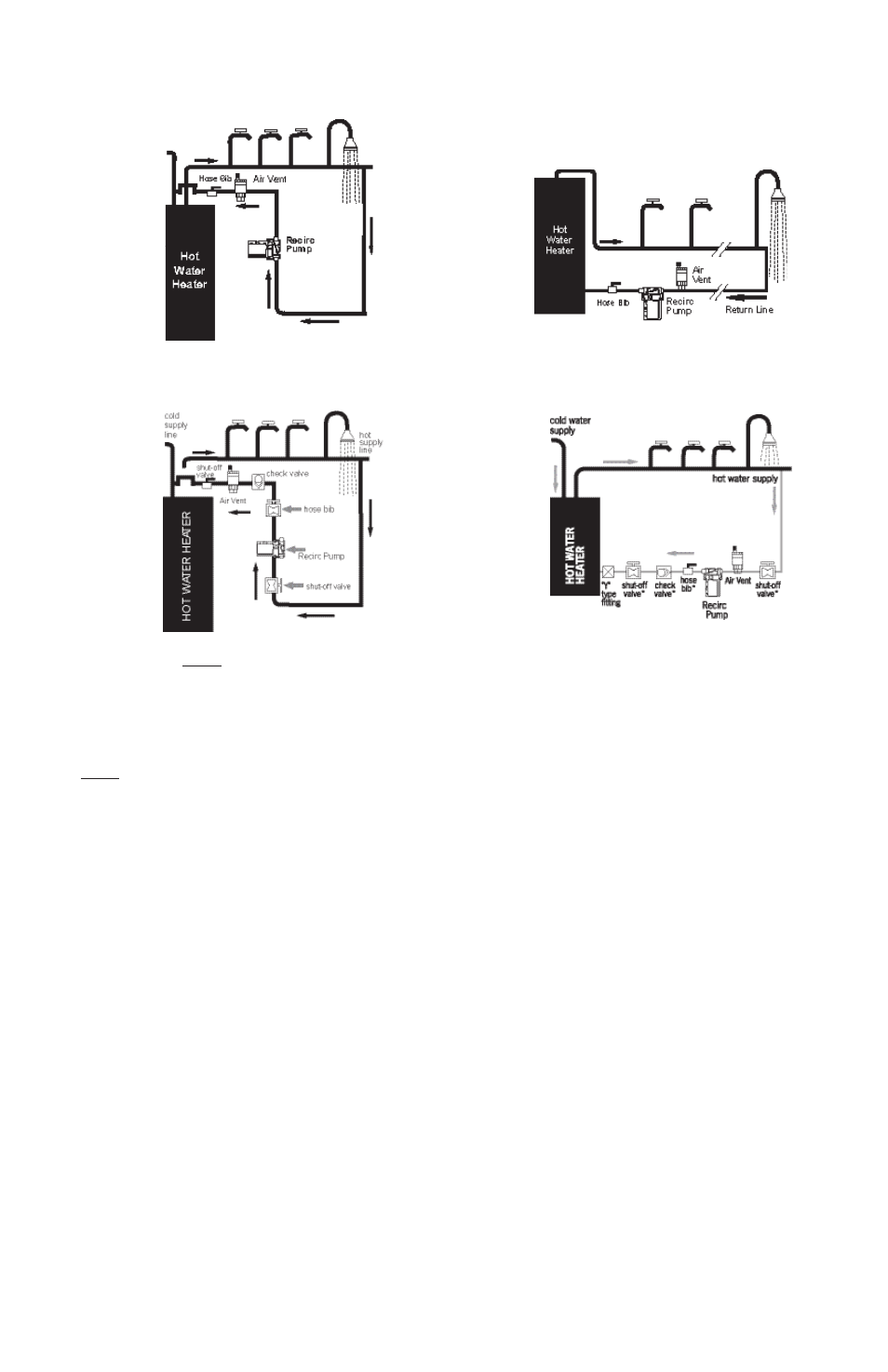

UC/UCT Models

A. Return into Cold Water Line at Top of Water

Heater fig. 1

B. Return to Drain Valve at Bottom of Water

Heater fig. 2

SM/SMT Models

A. Return into Cold Water Line at Top of Water

Heater fig. 3

B. Return to Drain Valve at Bottom of Water

Heater fig. 4

Note: The Air Vent and Hose Bib are not required with UC/UCT-01 models.

These models have a built-in air purge valve.

Above diagrams are for single line returns only. For multiple branched supply line installations, a

recirculation line should be installed for each branch.

Note: The pump must always be installed below the water level of water heater so that the pump flow

is always upward or directly horizontal and not downward. Do not mount the pump above the water

heater.

3. Purchase materials required.

• Laing ReCirc

®

(SM-303/353/UC-303/353 or SM-909/959) • (1)1/2”(5/8”) or 3/4” swing check valve

• Copper pipe or tubing

(not required on UC/UCT models)

• Tee for under sink connect

• (1) 1/2”(5/8”) or 3/4” hose bib/

• Tee or “Y” fitting connection to water heater

connection (not required on UC/UCT-01

• (2) 1/2” (5/8”) or 3/4” shut-off valves

models)

• Misc. nipples and fittings UC/UCT models)

• (1) Auto air vent

• Pipe insulation

(not required on UC/UCT-01 models)

4. Shut off the water to the house.

5. Drain the plumbing lines by opening the faucet/tap in the house. Drain the water heater if you plan

to make the connection at the bottom of the water heater, which requires removal of the drain valve.

6. Connect the return line at the last faucet/taps riser and run to the water heater. Tee the return line

as close to the end of the hot water supply line as possible and run the return line back to the water

heater.

7. Install the pump and other components required in accordance with the diagrams provided in fig. 1

or 2 and connect the return line to the water heater (also see fig. 3).

For SM(T) and UC(T) 303/353 Models Check pump operation before you begin. Unscrew the pump

housing from the motor (fig. 4) and run the pump for a few seconds to make sure it is operational.

Remove the rotor (see fig. 5) and add a little water to the bearing ball for lubrication. Do not use

grease or oil to lubricate the pump.