Xylem Palmer & Bowlus flumes User Manual

Palmer & bowlus flumes, Installation instructions

Installation Instructions

MJK Automation A/S

Byageren 7

DK-2850 Nærum

Denmark

Tel.: (+45) 45 56 06 56

Fax: (+45) 45 56 06 46

[email protected]

www.mjk.dk

MPBGB0204

As our products are developed continuously,

we reserve the right to make any changes without prior notice.

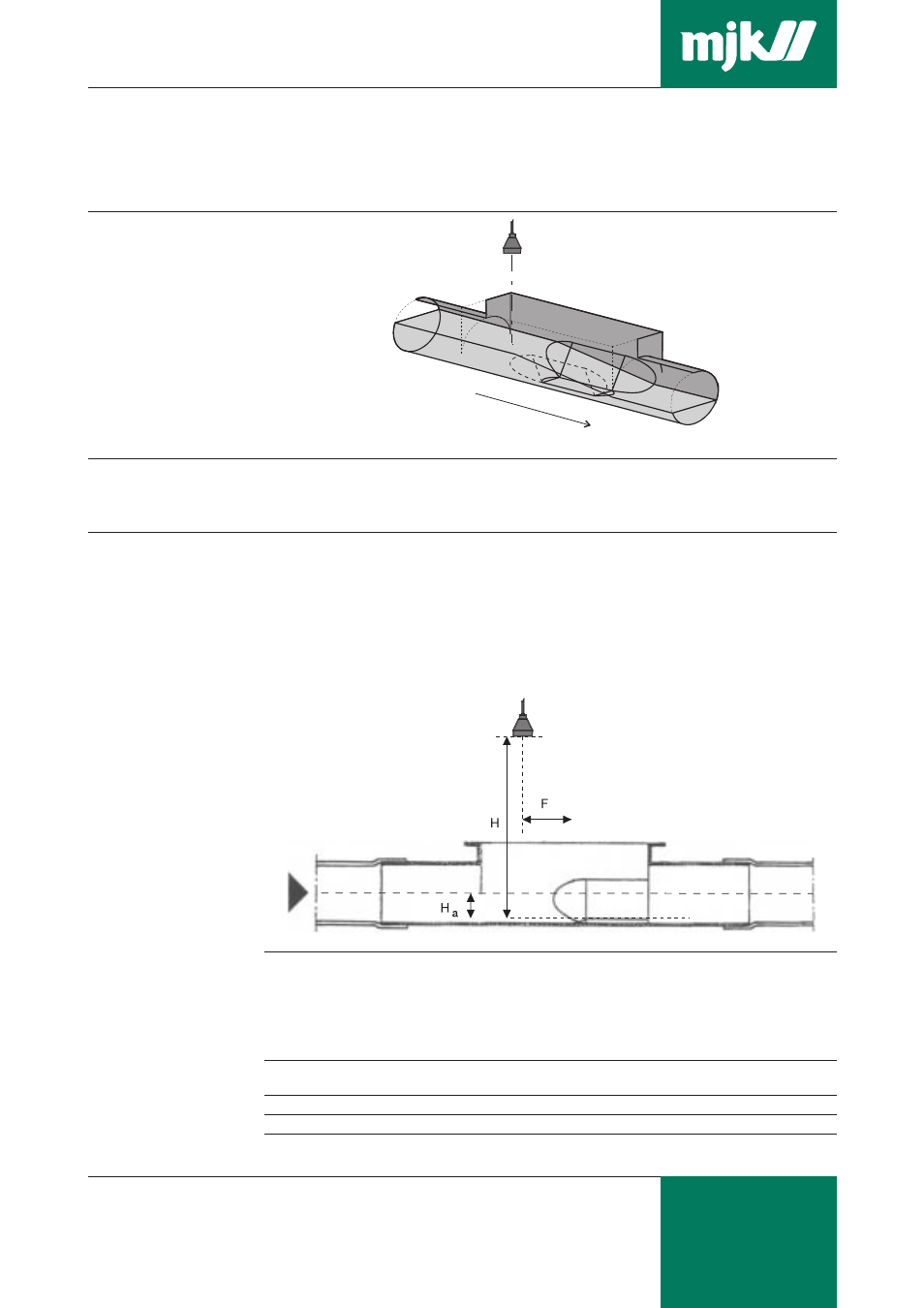

Palmer & Bowlus flumes

It is very important for the overall measuring

accuracy to comply with the installation

instructions on the next page.

The Palmer & Bowlus flume is characterized

by its circular connection which makes it

easy to install in pipelines.

The flume is aimed at measurement in the

scale of 20 - 100 % of the nominal flow.

No simple formula can be set up for the

Palmer & Bowlus flumes; the formulas are

defined individually for every flume.

General

Flume sizes

Size:

Q

min

Q

max

F

H

Ha

Weight

8”

DN 200 (

∅

200 mm)

14 m

3

/h

70 m

3

/h

100 mm

See note

151 mm

2.8 kg

10” DN 250 (

∅

250 mm)

22 m

3

/h

110 m

3

/h

125 mm

below.

179 mm

3.5 kg

12” DN 315 (

∅

315 mm)

40 m

3

/h

200 m

3

/h

150 mm

240 mm

4.8 kg

15” DN 400 (

∅

400 mm)

65 m

3

/h

325 m

3

/h

200 mm

277 mm

9.8 kg

24” DN 600 (

∅

600 mm)

220 m

3

/h

1100 m

3

/h

300 mm

453 mm

15.6 kg

30” DN 800 (

∅

800 mm)

330 m

3

/h

1750 m

3

/h

400 mm

540 mm

30.1 kg

Material:

8”, 10”, 12”:

Glass fibre reinforced polyester / PVC

15”, 24”, 30”: PVC

pH range:

pH 3 - 10

Temperature range:

- 20 … +30 °C, for short periods up to 90 °C

Note: Max. height H must never exceed the measuring range for the flowmeter + deadband.

Note!

For the Palmer & Bowlus flumes with the

dimensions as listed in the table below, the

flow formulas are defined and incorporated

in the flow converter and is chosen in the

menu “Programming of flow calculation”.