C-1500n, Fig. 5.2, Fig. 5.1 – Xylem C-1500N DIAPHRAGM PUMPS User Manual

Page 8

C-1500N

C-1500N

Page 8

Page 9

5.0

How To Operate The C-1500N

5.1

Adjusting the Pump Output- Standard models (fig. 5.1) - The C-1500N flow rate can be adjusted

within a range of 5% -100% of maximum output (20:1 turndown ration) by means of a mechanical, cam

type mechanism. The mechanism adjusts the pump’s stroke length to an infinite number of settings

within the flow range. Because the pump’s output is reduced by increasing the pressure of the system

being injected into, the amount of suction lift, and the viscosity of the fluid being injected, the pump

must be over-sized to allow for these factors. Sizing the pump to allow adjustment within the midrange

is preferred to maintain accuracy. Consult the factory for individual pump model output curve data.

To adjust the pump’s output:

1. With the pump running, loosen the set screw.

2. Turn the adjustment knob to the desired setting.

3. Re-tighten the set screw.

CAUTION

ADJUST WHILE RUNNING

DISCHARGE LINES MAY BE UNDER

HIGH PRESSURE. USE CARE TO

PROTECT YOURSELF WHEN

DISCONNECTING.

MAX

MIN

1

2

3

4

5

6

7

8

9

LOOSEN THE LOCK SCREW

TURN KNOB TO DESIRED SETTING

RE-TIGHTEN THE LOCK SCREW

5.3 Measuring the Pump’s Output - Volumetric Test.

This volumetric test will take into account individual installation factors such as line pressure, fluid

viscosity, suction lift, etc. This test is the most accurate for measuring the injector’s output in an individ-

ual installation.

1. Be sure the Injection Fitting and Footvalve/Strainer is clean and working properly.

2. With the injector installed under normal operating conditions, place the Footvalve/Strainer in a large

graduated cylinder.

3. Fill the graduated cylinder with the solution to be injected and run the injector until all air is removed

from the suction line and the solution enters the discharge tubing.

4. Refill the graduated cylinder, if necessary, and with the Footvalve completely submerged in the

solution, note the amount of solution in the graduated cylinder.

5. Run the injector for a measured amount of time and note the amount of fluid injected. A longer testing

time will produce more accurate results.

6.0

How to Maintain the C-1500N

6.1

Routine Inspection and Maintenance

The C-1500N requires very little maintenance. However, the pump and all accessories should be

checked regularly. This is especially important when pumping chemicals. Inspect all components for

signs of leaking, swelling, cracking, discoloration or corrosion. Replace worn or damaged components

immediately.

Cracking, crazing, discoloration and the like during the first week of operation are signs of severe

chemical attack. If this occurs, immediately remove the chemical from the pump. Determine which

parts are being attacked and replace them with parts that have been manufactured using more suitable

materials. The manufacturer does not assume responsibility for damage to the pump that has been

caused by chemical attack.

6.2

How to Clean the C-1500N

The C-1500N will require occasional cleaning, especially the Injection fitting, the Footvalve/Strainer,

and the pump head valves. The frequency will depend on the type and severity of service..

]

When changing the diaphragm, the pump head chamber and pump head cover should be wiped free of

any dirt and debris.

]

Periodically clean the injection/check valve assembly, especially when injecting fluids that calcify such

as sodium hypochlorite. These lime deposits and other build ups can clog the fitting, increase the back

pressure and interfere with the check valve operation. See section 4.3.4. Fig. 4.8.

]

Periodically clean the suction strainer. Fig.4.7

]

Periodically inspect the air vents located under the motor compartment and under the pump head. Clean

if necessary.

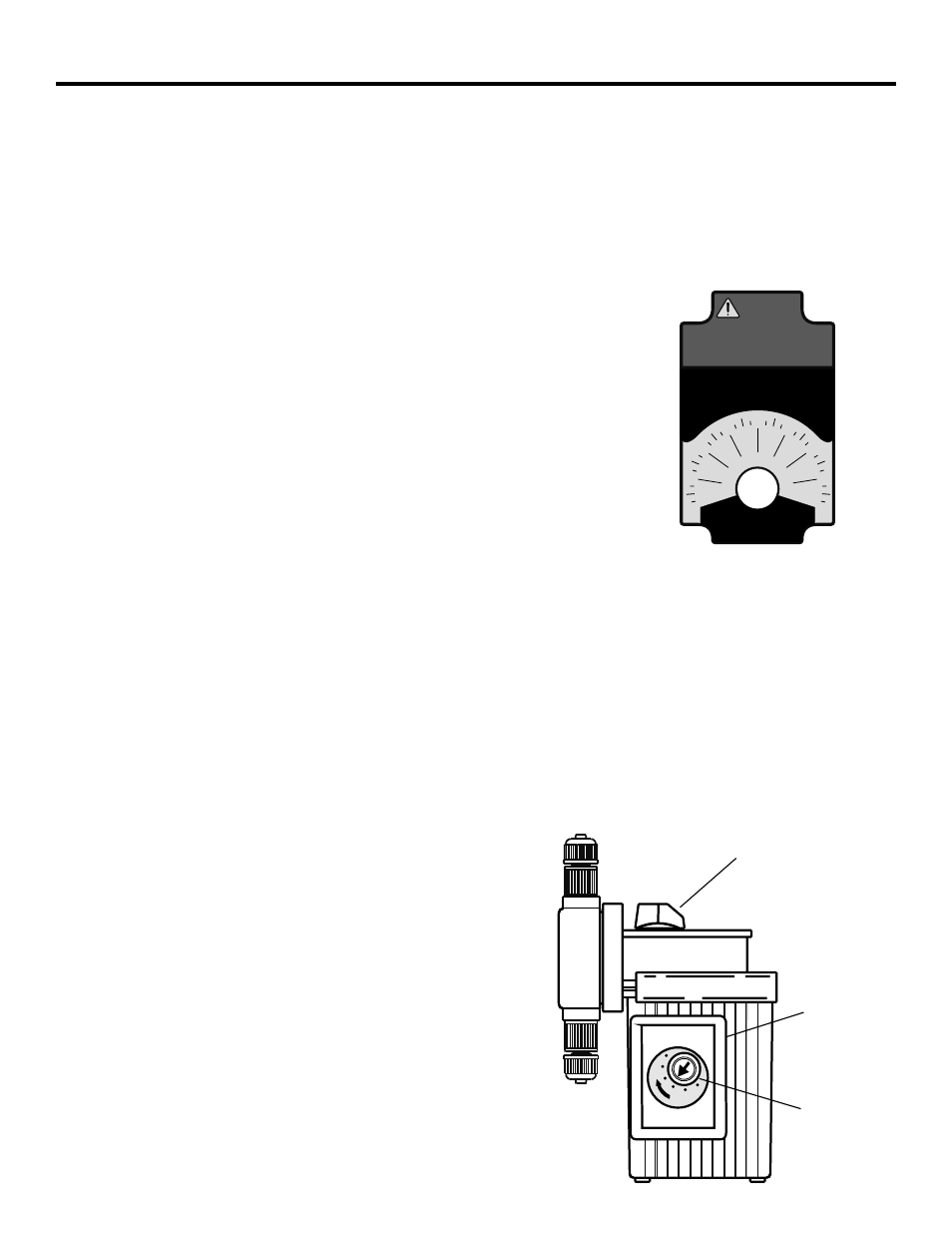

5.2

Adjusting the Pump Output - DELUXE Models (fig. 5.2)

In addition to the cam type mechanism adjustment (section 5.1), the pump output of the C-1500N deluxe

unit equipped with an optional electronic cycle timer board can also be fine tuned by adjusting the timer

adjustment knob. The total-time cycle is factory preset and is not user adjustable. The on-time cycle is

adjustable from 5% to 100% of the total cycle time. Example: If the total-time cycle is 5 seconds and the

on-time cycle is adjusted for 20 percent, the pump will run for 1 second and turn off for 4 seconds (5

second total cycle). This cycle is repeated until either the cycle time is changed or the input power is

disconnected from the pump.

Note: When the input power is disconnected from the C-1500N, the unit will maintain the last

adjusted settings. When power is restored to the pump, the C-1500N will begin to pump using the

last time cycle setting.

Junction Box

Cycle Timer

Adjustment Knob

FIG. 5.2

To adjust the On-Time :

Turn the timer adjustment knob located on the

junction box cover.

Clockwise increases the time on.

FIG. 5.1

Adjustment Knob

(Cam Type Mechanism)