Specifications* general information, Tables and diagrams, Features – Xylem EX80-Series INSERTION MAGMETERS User Manual

Page 3

SPECIFICATIONS*

GENERAL INFORMATION

Page 1

TABLES AND DIAGRAMS

EX80-Series insertion electromagnetic flowmeters are designed

for use with conductive liquids in 1 to 12” pipe. A choice of

materials (stainless steel, brass, and PVC) allows the meter

to adapt to a range of temperature, pressure, and corrosive

environments.

The EX80 is highly suitable for difficult applications with changing

viscosities and pulsating flows, such as air-driven diaphragm

pumps. With no moving parts, these meters can be used in

“dirty” applications where debris would foul a mechanical

meter. Like all magmeters, when used in chemical injection

applications, these meters should be installed upstream of the

chemical line (or far enough downstream to allow complete

mixing of fluids before the meter).

Designed for modularity and versatility, the EX80-Series has

a current-sinking pulse output that can be combined with the

appropriate transmitter or indicator for the application. For

analog output and display of rate and total, an FT420 can be

used. Blind analog output is provided by the AO55. The PD10

can be used to divide the pulse for pacing chemical metering

pumps and the DL76 (data logger) is also compatible. Modules

can be wall- or meter- mounted. If the EX80 meter is used with

a programmable controller, the output signal can be fed direct,

with no other conditioning required.

EX80-Series fixed depth insertion meters require special

fittings. Factory installation in the fitting ensures correct depth

placement in the pipe. The EX80-Series meter can be ordered

in a full power model when a source of electricity is available,

or in a low power model that can run on an external battery

with solar panel.

Reverse flow output and immersibility are optional.

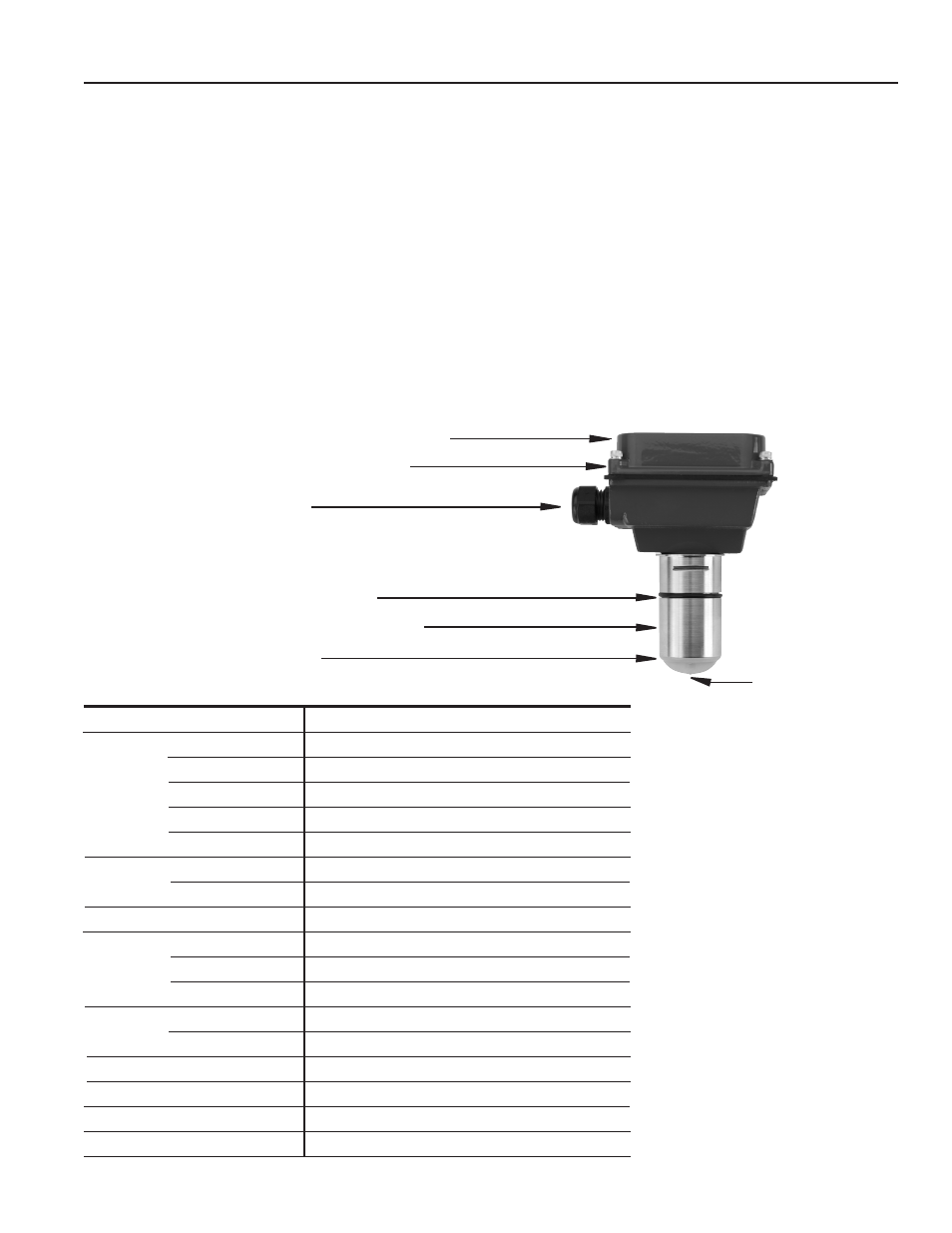

FEATURES

PVDF electrode cap

O-ring, EPDM (Viton optional)

Cover, or transmitter or indicator module

Powder coated aluminum housing

Sensor body (Stainless, Brass, PVC)

Hastelloy electrodes

Cable strain relief

1” to 12”

316 SS/Brass/PVC

Hastelloy

Cast powder-coated aluminum

PVDF (Kynar)

EPDM standard (Viton optional)

12 - 25 Vdc, 250 mA

12 - 25 Vdc, 40 mA average with 250 mA peaks

0.28 - 20 ft/sec (0.08 - 6.09 m/sec)

0˚ to 160˚ F (-17˚ to 72˚ C)

32˚ to 200˚ F (0˚ to 93˚ C)

32˚ to 130˚ F (0˚ to 55˚ C) @ 0 psi

200 psi (13.8 bar)

150 psi (10 bar) @ 75˚ F

20 microSiemens/cm

+/- 1% of full scale

Square wave pulse, opto isolated, 550 Hz @ 20 ft/sec

Software, defaults to zero flow

Pipe Size

Materials Mechanical

Electrodes

Housing

Electrode Cap

O-Ring

Power

Full Power

Low Power

Flow Rate

Temperature Ambient Temp

Fluid Temp : Brass/SS

Fluid Temp: PVC

Pressure Brass/SS

PVC

Minimum Conductivity

Calibration Accuracy

Output

Empty Pipe Detection

*Specifications subject to change • Please consult our website for current data (www.seametrics.com).