Maintenance – Xylem Heat Exchangers User Manual

Page 6

1

Clean exchangers subject to fouling

(scale, sludge deposits, etc.) periodi-

cally, depending on specific conditions.

A light sludge or scale coating on either

side of the tube greatly reduces its

effectiveness. A marked increase

in pressure drop and/or reduction in

performance usually indicates cleaning is

necessary. Since the difficulty of cleaning

increases rapidly as the scale thickens or

deposits increase, the intervals between

cleanings should not be excessive.

2

Neglecting to keep tubes clean

may result in random tube plugging.

Con sequent over heating or cooling of

the plugged tubes, as compared to

surrounding tubes, will cause physical

damage and leaking tubes due to differ-

ential thermal expansion of the metals.

3

To clean or inspect the inside of the

tubes, remove only the necessary tube

side channel covers or bonnets, depend-

ing on type of exchanger construction.

4

If the heat exchanger is equipped with

sacrificial anodes or plates, replace these

as required.

5

To clean or inspect the outside of the

tubes, it may be necessary to remove the

tube bundle. (Fixed tubesheet exchanger

bundles are non-removable).

6

When removing tube bundles from heat

exchangers for inspection or cleaning,

exercise care to see that they are not

damaged by improper handling.

• The weight of the tube bundle should

not be supported on individual

tubes but should be carried by the

tube sheets, support or baffle plates or

on blocks contoured to the periphery

of the tube bundles.

• Do not handle tube bundles with hooks

or other tools which might damage tubes.

Move tube bundles on cradles or skids.

• To withdraw tube bundles, pass rods

through two or more of the tubes and

take the load on the floating tubesheet.

• Rods should be threaded at both ends,

provided with nuts, and should pass

through a steel bearing plate at each

end of the bundle.

• Insert a soft wood filler board between

the bearing plate and tubesheet face to

prevent damage to the tube ends.

• Screw forged steel eyebolts into both

bearing plates for pulling and lifting.

• As an alternate to the rods, thread a

steel cable through one tube and return

through another tube.

• A hardwood spreader block must be

inserted between the cable and each

tubesheet to prevent damage to the

tube ends.

7

If the heat exchanger has been in service

for a considerable length of time without

being removed, it may be necessary to use

a jack on the floating tubesheet to break

the bundle free.

• Use a good-sized steel bearing plate

with a filler board between the

tubesheet face and bearing plate to

protect the tube ends.

8

Lift tube bundles horizontally by means

of a cradle formed by bending a light-

gauge plate or plates into a U-shape.Make

attachments in the legs of the U for lifting.

9

Do not drag bundles, since baffles or

support plates may become easily bent.

Avoid any damage to baffles so that the

heat exchanger will function properly.

10

Some suggested methods of cleaning

either the shell side or tube side are listed

below:

• Circulating hot wash oil or light distil-

late through tube side or shell side will

usually effectively remove sludge or

similar soft deposits.

• Soft salt deposits may be washed out

by circulating hot fresh water.

• Some commercial cleaning compounds

such as “Oakite” or “Dowell” may be

effective in removing more stubborn

deposits. Use in accordance with the

manufacturer’s instructions.

11

Some tubes have inserts or longitudinal

fins and can be damaged by cleaning

when mechanical means are employed.

Clean these types of tubes chemically or

consult the nearest ITT Heat Transfer rep-

resentative for the recommended method

of cleaning.

• If the scale is hard and the above meth-

ods are not effective, use a mechanical

means. Neither the inside nor the out-

side of the tube should be hammered

with a metallic tool. If it is necessary to

use scrapers, they should not be sharp

enough to cut the metal of the tubes.

Take extra care

when employing scra-

pers to prevent tube damage.

Do not attempt to clean tubes by

blowing steam through individual tubes.

This overheats the individual tube and

results in severe expansion strains and

leaking tube-to-tubesheet joints.

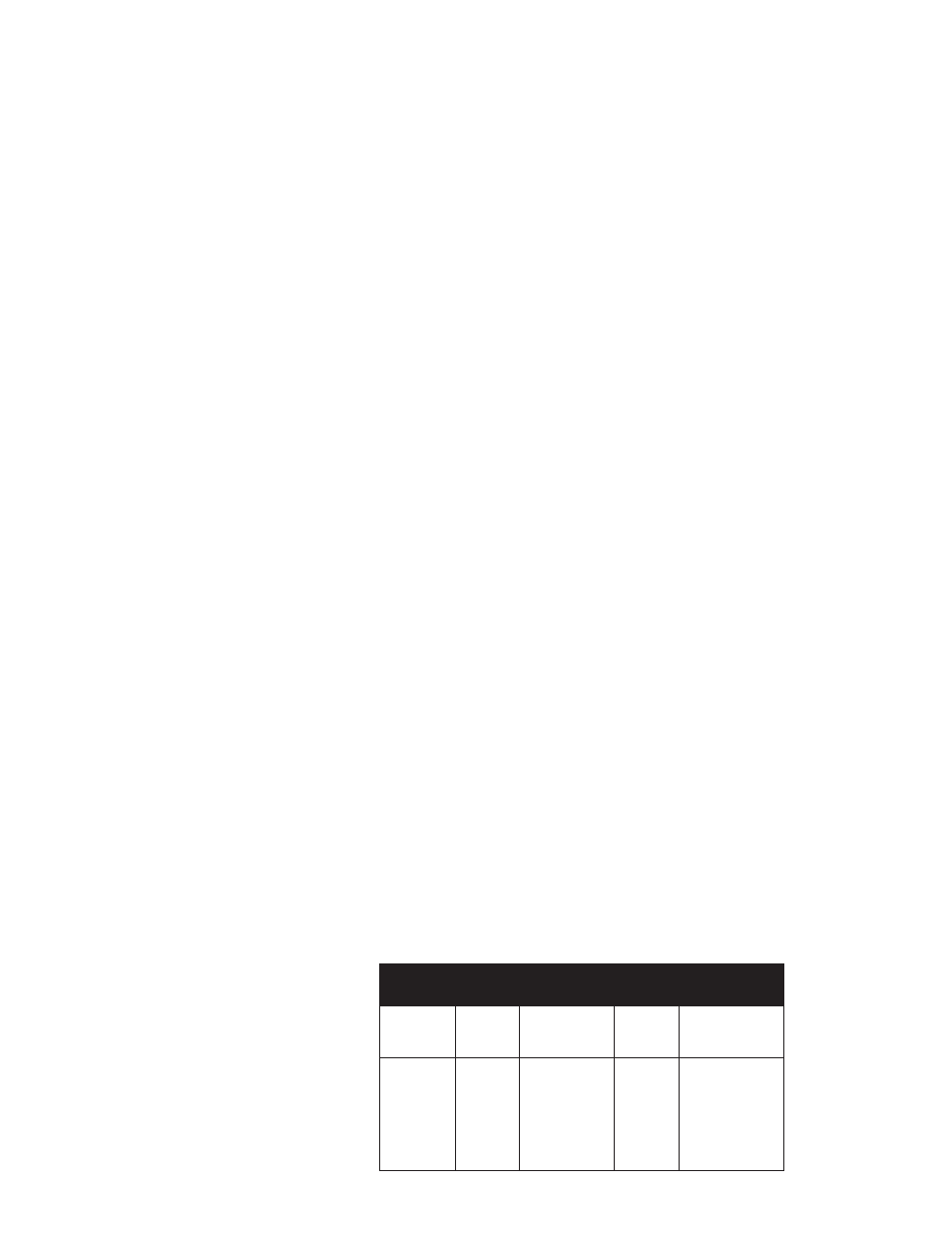

12

Table 2 shows safe loads for steel rods

and eyebolts.

Maintenance

STEEL ROdS

STEEL EyEBOLTS

Tube

Rod

Safe Load

Size

Safe Load

Size

Size

Per Rod

5/8”

3/8”

1,000 lbs.

3/4”

4,000 lbs.

3/4”

1/2”

2,000 lbs.

1”

6,000 lbs.

1” or

1-1/4”

10,000 lbs.

larger

5/8”

3,000 lbs.

1 -1/2”

15,000 lbs.

taBle 2

6