Technical data, Frequency of starts, Mounting position – Xylem IM103 R03 5 and Larger Submersible Pump User Manual

Page 11: Motor cooling, temperature and time ratings

11

Technical Data

(Continued)

Technical Data

Transformer Capacity Required for Submersible

Motors – Single or Three Phase

Distribution transformers must be adequately sized to satisfy

the KVA requirements of the submersible motor. When

transformers are too small to supply the load, there is a

reduction in voltage to the motor.

Table 1 references the motor horsepower rating, single

phase and three phase, total effective KVA required, and the

smallest transformer required for open or closed three phase

systems. Open systems require larger transformers since only

two transformers are used.

Other loads would add directly to the KVA sizing require-

ments of the transformer bank.

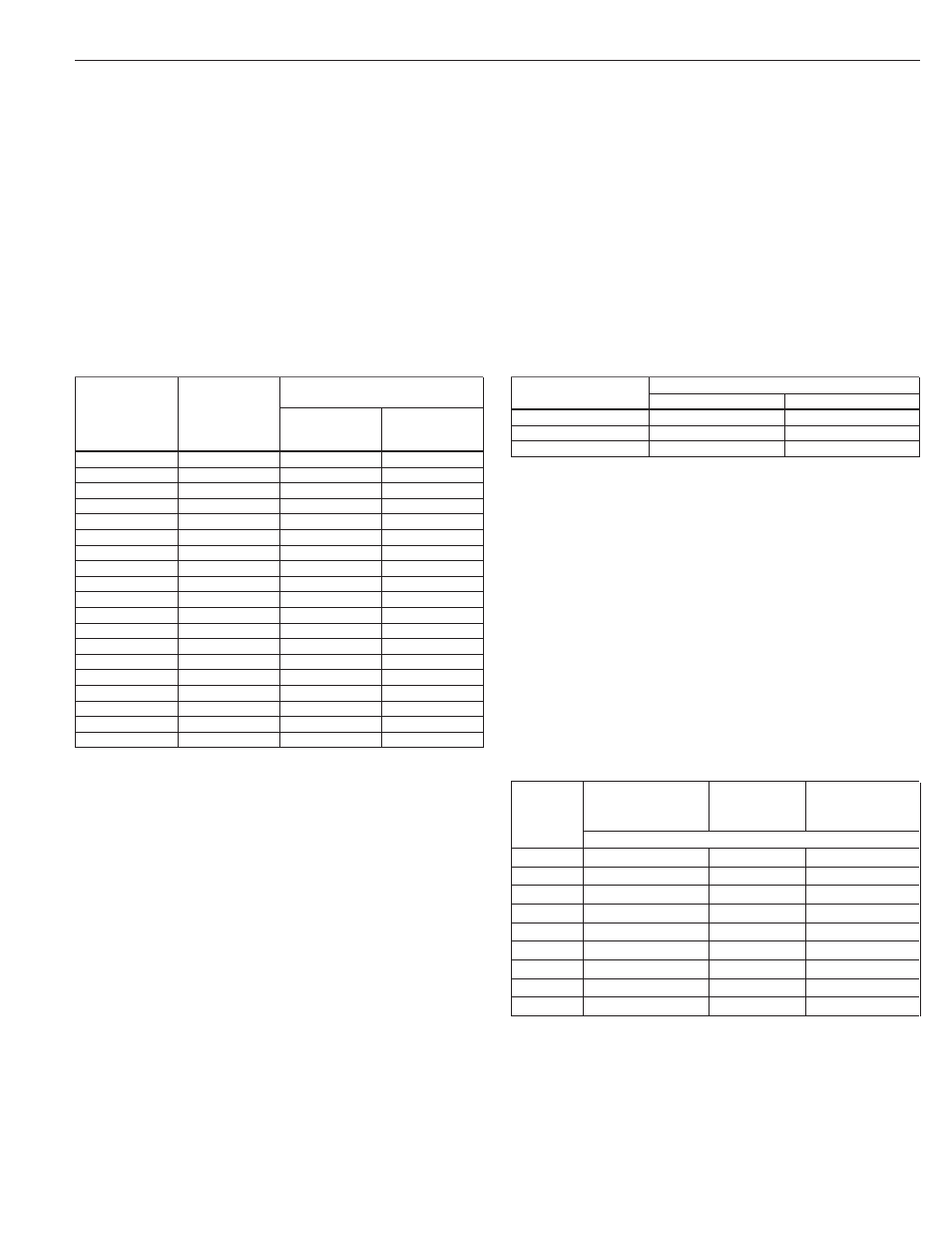

Table 1 – Transformer Capacity

Smallest KVA Rating –

Each Transformers

Motor HP

Open WYE

Closed

Total Effective

or DELTA

WYE or DELTA

KVA Required 2 Transformers 3 Transformers

1½

3

2

1

2

4

2

1.5

3

5

3

2

5

7.5

5

3

7½

10

7.5

5

10

15

10

5

15

20

15

7.5

20

25

15

10

25

30

20

10

30

40

25

15

40

50

30

20

50

60

35

20

60

75

40

25

75

90

50

30

100

120

65

40

125

150

85

50

150

175

100

60

175

200

115

70

200

230

130

75

NOTE: Transformers shown are standard nominal KVA ratings. If power company experience

and practice allows transformer loading higher than nominal rating under the specific operat-

ing conditions and maintains correct voltage and balance, such higher loading values may be

used for transformer(s) to meet total effective KVA required.

Table 2 – Number of Starts

Maximum Starts per 24 hour day

Motor Rating

Single Phase

Three Phase

½ HP through 5 HP

100

300

7½ HP through 30 HP

50

100

40 HP and over

—

100

Frequency of Starts

The average number of starts per day over a period of

months or years influences the life of a submersible pumping

system. Excessive cycling affects the life of control compo-

nents such as pressure switches, starters, relays and capaci-

tors, plus splines and bearings. Rapid cycling can also cause

motor overheating and winding failures.

The pump size, tank size and other controls should be select-

ed to keep the starts per day as low as practical for longest

life, based upon the maximum number of starts per 24 hour

day, as shown in Table 2.

Motors over 2 HP should be allowed to run a minimum of

2 minutes to dissipate heat build up from starting current.

Mounting Position

Motors are suitable for operation in mounting positions

from vertical shaft up to horizontal. If 4 inch motors through

2 HP are started more than 10 times per day, it is recom-

mended the shaft be tilted up at 15° from horizontal to

minimize coast-down wear of the upthrust washer.

Motor Cooling, Temperature and Time Ratings

All 4 inch CentriPro motors may be operated continuously

in water up to 86º F. Optimum service life will be attained

by maintaining a minimum flow rate past the motor of .25

feet per second. Use a Flow Sleeve if velocity is below the

.25'/sec, if the well is top feeding or when the pump is used

in a large body of water or large tank.

Six (6) inch canned design motors from 5 – 40 HP will

operate in water up to 95º F (35º C), without any de-rating

of horsepower, with a minimum flow rate of .5 ft./sec. past

the motor. 6" – 50 HP and all 8" – 10" motors can operate in

77º F (25º C) water with .5'/sec velocity past the motor.

Table 3 – Minimum Flow Rates For Proper Motor Cooling

Well or

3.75" Diameter

CP = 5.5" Dia. CP = 7.52" Dia.

Sleeve

4" CP or FE Motor

6" CP Motor

8" CP Motor

Diameter

.25'/sec

.5'/sec.

.5'/sec.

(inches)

GPM Required

4

1.2

–

–

5

7

–

–

6

13

7

–

7

20

23

–

8

30

41

9

10

50

85

53

12

80

139

107

14

110

198

170

16

150

276

313

Multiply gpm by .2271 for m

3

/Hr.

Multiply gpm by 3.785 for l/min.