Simplex, Duplex, Slide rail systems – a10-60 – Xylem IM042 R03 Slide Rail Systems Series A10 & APD User Manual

Page 5

5

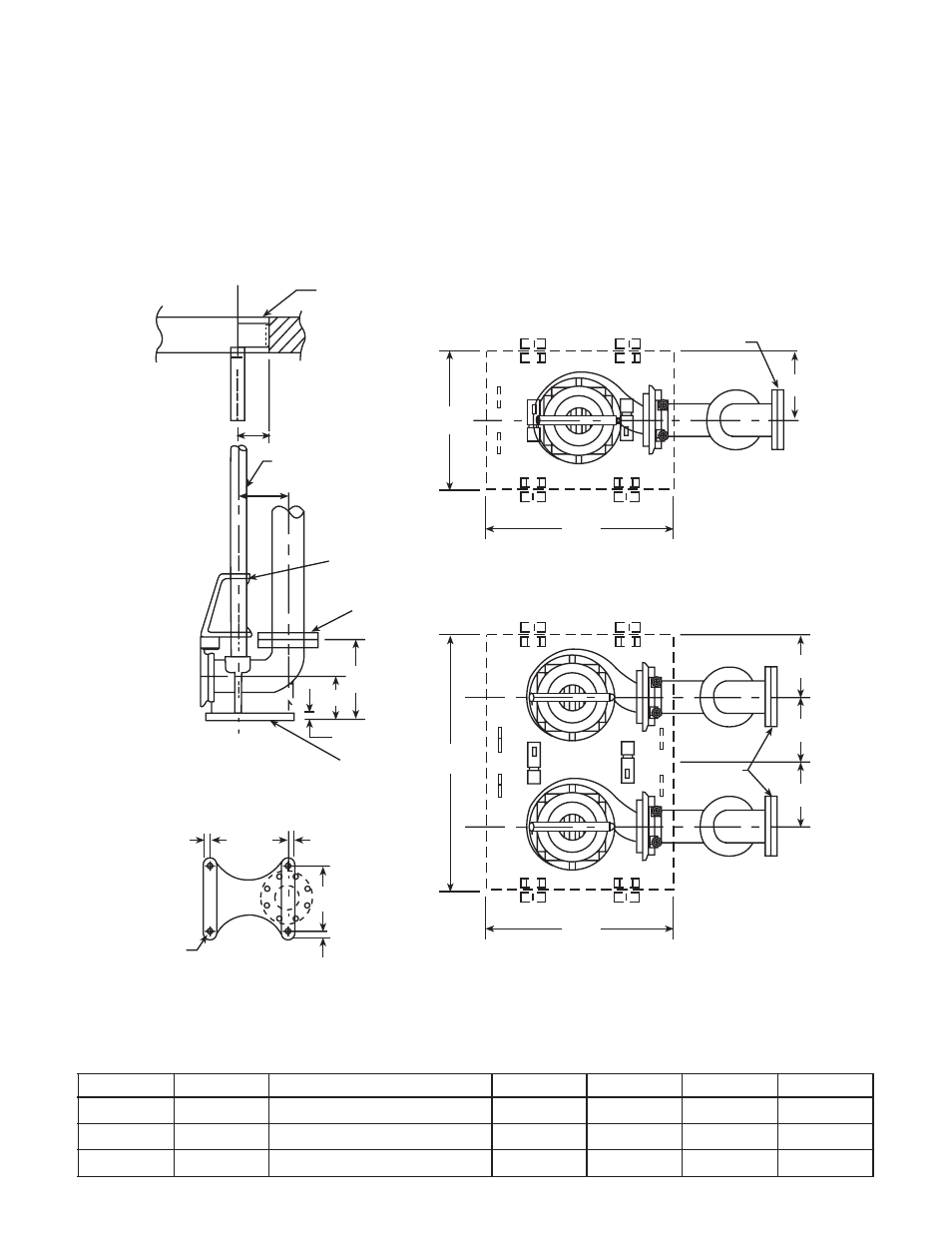

Slide Rail Systems – A10-30 and A10-40

The A10-30 system is designed for pumps with a 3",

125# ANSI flanged discharge. The A10-40 system

is designed for pumps with a 4", 125# ANSI flanged

discharge. Both 3" and 4" flanged pumps bolt directly to

their respective slide rail cast iron pump adapters. The

adapter, which slides up and down on the rails, mates

with the slide rail base and the integrally cast elbow

to provide a 4", 125# ANSI flanged discharge connec-

tion. See Figure 2 and Table 2 for the typical hardware

specifications, piping arrangements and basin attachment

dimensions.

Upper Guide Rail

Position Bracket

2

5

/

8

”

2” Guide Pipe

(by customer)

A

Pump Adapter and

Guide Assembly

B

C

D

1”

Base

with Integral

Cast Elbow

11”

1

1

/

2

” Typical

E

F

Typical

4 -

7

/

8

”

DIA Holes

24”

32”

SIMPLEX

Discharge

12”

11”

DUPLEX

11”

11”

Discharge

44”

32”

Slide Rail Systems – A10-60

The A10-60 system is designed for pumps with a 4",

125# ANSI flanged discharge. The pump bolts directly

to the slide rail cast iron pump adapter, mating with the

slide rail base and integrally cast elbow to provide a 6",

125# ANSI flanged discharge connection. See Figure 2

and Table 2 for the typical hardware specifications, pip-

ing arrangements and basin attachment dimensions.

A10-30, A10-40 and A10-60

Figure 2

Table 2

SIZE

A"

B

C"

D"

E"

F"

A10-30

7¼

4" ANSI 125# Flange

12

7

13

1

A10-40

7

5

/

18

4" ANSI 125# Flange

12

7

13

1

A10-60

8

5

/

16

6" ANSI 125# Flange

17

10

15

2