Warning, Safety instructions – Xylem IM042 R03 Slide Rail Systems Series A10 & APD User Manual

Page 3

3

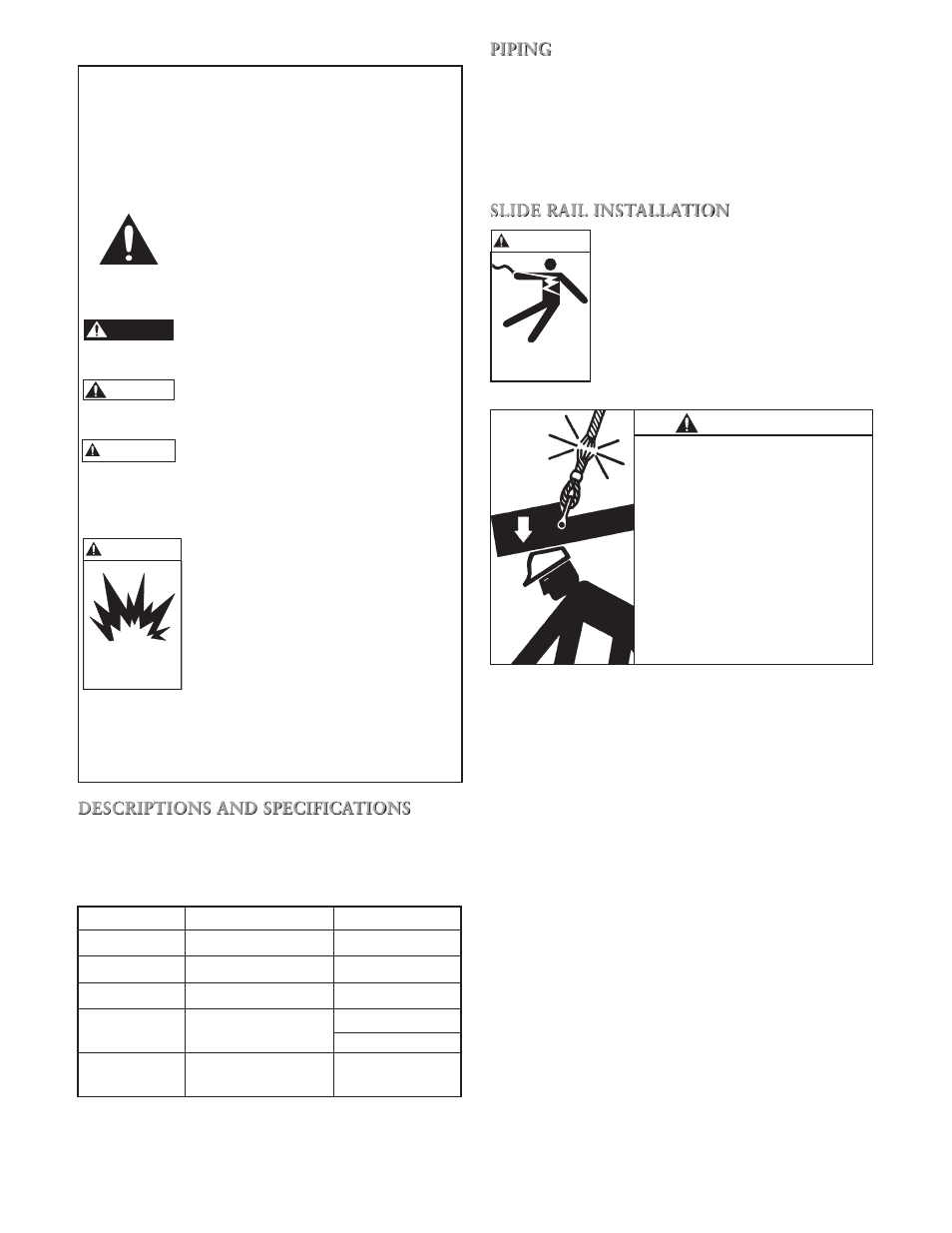

SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL

INJURY OR MAJOR PROPERTY DAMAGE, READ

AND FOLLOW ALL SAFETY INSTRUCTIONS IN

MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE SLIDE RAIL.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the fol-

lowing signal words and be alert to the

potential for personal injury or property

damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause per-

sonal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

HAZARDOUS LIQUIDS OR

FLAMMABLE GASES CAN CAUSE

FIRE, BURNS OR DEATH.

THOROUGHLY REVIEW ALL

INSTRUCTIONS AND WARNINGS

PRIOR TO PERFORMING ANY

WORK ON THIS UNIT.

MAINTAIN ALL SAFETY DECALS.

NOTICE: INSPECT UNIT FOR DAMAGE AND

REPORT ALL DAMAGE TO THE

CARRIER OR DEALER IMMEDIATELY.

DESCRIPTIONS AND SPECIFICATIONS

Goulds Pumps A10 slide rail systems provide easy wet

well pump removal, utilize a self-cleaning quick discon-

nect and guide assembly, and eliminate the need to enter

the wet well.

Model

Slide Rail Discharge Pump Discharge

A10-12

1¼” NPTM

1¼” F

A10-2015

1½” NPTM

1½” F

A10-20

2” NPTM

2” F

A10-30 and

4” 125#

3” ANSI Flange

A10-40

ANSI Flange

4” ANSI Flange

A10-60

6” 125#

4” ANSI Flange

ANSI Flange

DANGER

WARNING

CAUTION

PIPING

System piping MUST conform to all local and national

plumbing codes and practices.

To maximize the discharge flow, discharge piping should

be at least as large as the pump discharge. Keep the

discharge pipe as short as possible and avoid unnecessary

fittings.

SLIDE RAIL INSTALLATION

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE

SHOCK, BURNS OR DEATH.

NOTICE: ALL DIMENSIONS ARE IN INCHES. DO

NOT USE DIMENSIONAL DATA FOR

CONSTRUCTION PURPOSES.

Installation of the slide rail system should locate the pump

opposite the influent opening, preventing stagnate areas

where solids can settle.

NOTICE: GUIDE RAILS MUST BE PLUMB TO

FACILITATE PUMP(S) INSTALLATION

OR REMOVAL.

The containment area floor MUST be flat under the slide

rail base and have sufficient loading capacity to support

the entire weight of the assembly, including the slide rail

base, slide rail guide, pump and all assorted piping.

Prior to anchoring the slide rail base to the containment

area floor, ensure adequate clearance for pump(s) instal-

lation or removal AND for access doors.

NOTICE: MATERIAL SELECTION FOR

CONTAINMENT AREA EQUIPMENT

MUST BE COMPATIBLE WITH

ANTICIPATED FLUIDS AND SERVICE.

WARNING

Hazardous voltage

can shock, burn or

cause death.

WARNING

Hazardous fluids

can cause fire,

burns or death.

WARNING

Wire rope WILL FAIL if worn-out, overloaded, misused,

damaged, improperly maintained or abused.

Wire rope failure may cause serious injury or death!

Protect yourself and others:

• ALWAYS INSPECT wire rope for, WEAR, DAMAGE or

ABUSE BEFORE USE.

• NEVER USE wire rope that is WORN-OUT, DAMAGED

or ABUSED.

• NEVER OVERLOAD a wire rope.

• INFORM YOURSELF: Read and understand

manufacturer’s literature or “Wire Rope and Wire

Rope Sling Safety Bulletin”.*

• REFER TO APPLICABLE CODES, STANDARDS and

REGULATIONS for INSPECTION REQUIREMENTS and

REMOVAL CRITERIA.*

* For additional information or the BULLETIN, ask your

employer or wire rope supplier.

© 1993, Wire Rope Technical Board

Form No. 193