Xylem IM010 R08 Model 3656/3756 User Manual

Page 10

10

11. Apply LOCTITE

®

#271 or equivalent, to new impeller bolt

threads and tighten to:

3

⁄

8

"-16 bolts

20 lbs.-ft. (27 N.m)

½"-13 bolts

38 lbs.-ft. (51 N.m)

Impeller bolt not used for SAE units.

12. For SAE units apply LOCTITE

®

#271 to the external

threads of the shaft and internal threads of the impeller

nut (22). Tighten impeller nut to the following:

½"-Impeller Nut (SAE M-Group) 80 lbs.-ft. (107 N.m)

¾"-Impeller Nut (SAE L-Group) 100 lbs.-ft. (134 N.m)

13. For SAE units, after impeller nut (22) has been installed,

apply

LOCTITE

®

#271 to set screw (22A). Install impeller

set screw into face of impeller nut (22) and tighten

hand-tight.

14. Replace casing wear ring, if removed.

15. Replace casing bolts and tighten, in a crossing sequence,

to torque values indicated below:

3

⁄

8

"-16 bolts (bronze casing)

25 lbs.-ft. (34 N.m)

½"-16 bolts (cast iron casing)

37 lbs.-ft. (50 N.m)

½"-13 bolts (cast iron casing)

90 lbs.-ft. (122 N.m)

¾"-10 bolts (cast iron casing)

175 lbs.-ft. (237 N.m)

16. Check reassembled unit for binding by rotating shaft with

appropriate tool from motor end.

17. If rubbing exists, loosen casing bolts and proceed with

tightening sequence again.

18. Replace motor hold-down bolts and motor end plug or

cover on close-coupled units.

19. Replace coupling, spacer, coupling guard and frame

hold-down bolts on frame-mounted units.

NOTICE: ALWAYS RECHECK BOTH ALIGNMENTS

AFTER MAKING ANY ADJUSTMENTS.

20. Refer to the “COUPLING ALIGNMENT” section of

this manual to realign shaft.

21. Assembly is complete.

Packed Box

1. Make sure stuffing box is free of foreign materials and

clean before beginning packing of packed box. Refer to

Sectional Assembly in the repair parts section.

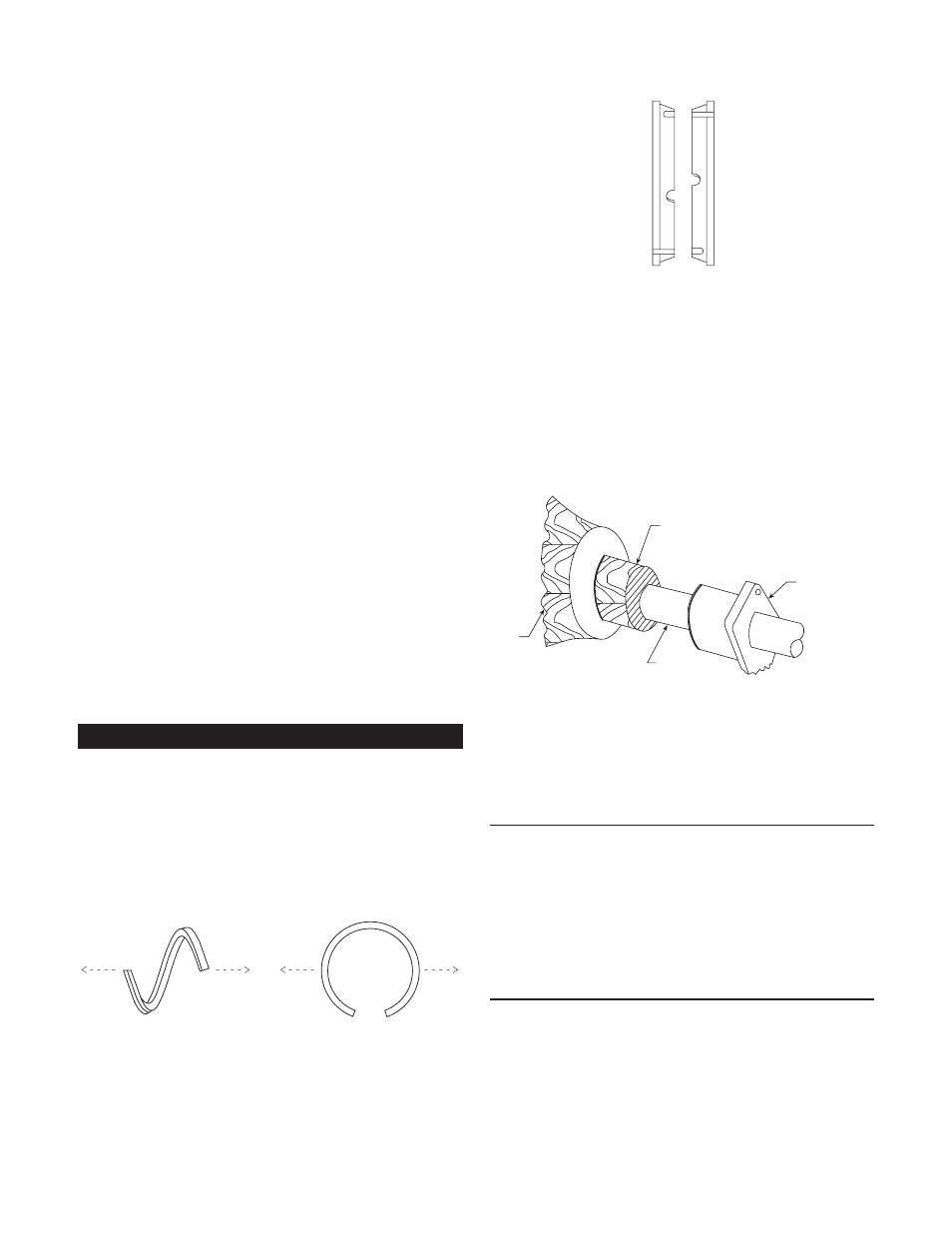

2. Take special care during installation of packing rings

because they are die-formed. To install, twist the ring

sideways just enough to fit it around the shaft sleeve.

DO NOT ATTEMPT TO PULL RINGS STRAIGHT

OUT. See Figure 12.

Figure 12

CORRECT

WRONG

3. Install the two piece Teflon lantern ring supplied as shown

in figure 13. Note: two pieces make one ring. Notches on

ring must face each other, but alignment is not necessary.

4. Install the packing rings and lantern ring in the following

sequence to pack the packed box. Install two rings of

packing, then the lantern ring, followed by the final three

rings of packing. Install each ring separately and firmly

seat. The use of a wooden split bushing is recommended

to accomplish this. See Figure 14. Use gland to jack the

bushing and ring into the box. Stagger joints in each ring

90°. Make sure the flush tap in the packed box lines up

with the center of the lantern ring. Any extra rings are

spares.

5. Tighten gland nuts evenly, but not tight. When the pump

is started, slowly tighten the gland nuts until the leak rate

is between 40 and 60 drops per minute. A grease lubricant

can be used when the pumpage contains abrasive particles

or for a suction lift condition.

REMOVAL OF PACKED BOX

• Follow these steps to remove the packing from the

packed box.

1. Remove gland assembly.

2. With a “packing hook” remove packing.

3. Insert a wire hook into the ring on the outer edge to

remove the lantern ring.

4. Clean the packed box.

PRIME SAFE ARRANGEMENT (Optional – M & L Group Only)

• The Prime Safe arrangement can be provided with grease or

an oiler feed lubrication.

1. The grease gland (24) will have the letters "G" and "O"

stamped on the outside diameter and have two

1

⁄

8

" NPT

connections for mounting a grease feeder or oiler.

Teflon Lantern Ring

Figure 13

Figure 14

STUFFING

BOX

WOODEN “SPLIT BUSHING”

SHAFT

GLAND