Xylem AQCPCQR Aquavar CPC Quick Reference Start-Up Guide User Manual

Aquavar® cpc, Centrifugal pump controller quick start guide, Quickstart guide

AQUAVAR® CPC

Centrifugal Pump Controller

Quick Start Guide

Overview

The installation of the AQUAVAR CPC adjust-

able speed drive follows the outline below.

Task

PREPARE for installation

UNPACK the drive

PREPARE mounting location

REMOVE the front cover

MOUNT the drive

INSTALL wiring

CHECK installation

REINSTALL the cover

APPLY power

START-UP Wizards

Application

This guide provides a quick reference for

installing Aquavar CPC drives having a

standard enclosure (NEMA 1).

NOTE: This guide does not provide

detailed installation, safety or operational

instructions. See the Installation Operation

Manual for complete information.

Prepare for Installation

WARNING! The Aquavar should ONLY

be installed by a qualified electrician.

Check

• Motor Compatibility – Motor type, nominal current,

frequency and voltage range must match drive

specifications (3 phase motor only).

• Suitable Environment – Drive requires heated,

indoor controlled environment that is suitable for

the selected enclosure.

• Wiring – Follow local codes for wiring and fusing

requirements. Refer to NEC.

Refer to the Installation Operation Manual and

confirm that all preparations are complete.

Tools Required

Screwdrivers, wire stripper, tape measure,

mounting screws or bolts, and drill.

Use the following chart to interpret the type code

found on the drive label.

Collect Motor Data

Collect the following data from the motor name-

plate for later use in the Aquavar startup:

• Voltage ______________________________

• Nominal Motor Current _______________

• Nominal Frequency ___________________

• Nominal Speed ______________________

• Nominal Power _______________________

Unpack the Drive

NOTE: Lift the Aquavar by its chassis and not by

its cover.

1. Unpack the drive.

2. Check for any damage and notify the

shipper immediately if damaged com-

ponents are found.

3. Check the contents against the order

and the shipping label to verify that all

parts have been received.

Prepare the Mounting Location

The drive requires a smooth,

vertical, solid surface, free from

heat and moisture, with free

space for air flow – 200 mm (8

in.) above and below, and 25

mm (1 in.) around the sides of

the drive.

1. Mark the mounting

points.

2. Drill the mounting holes.

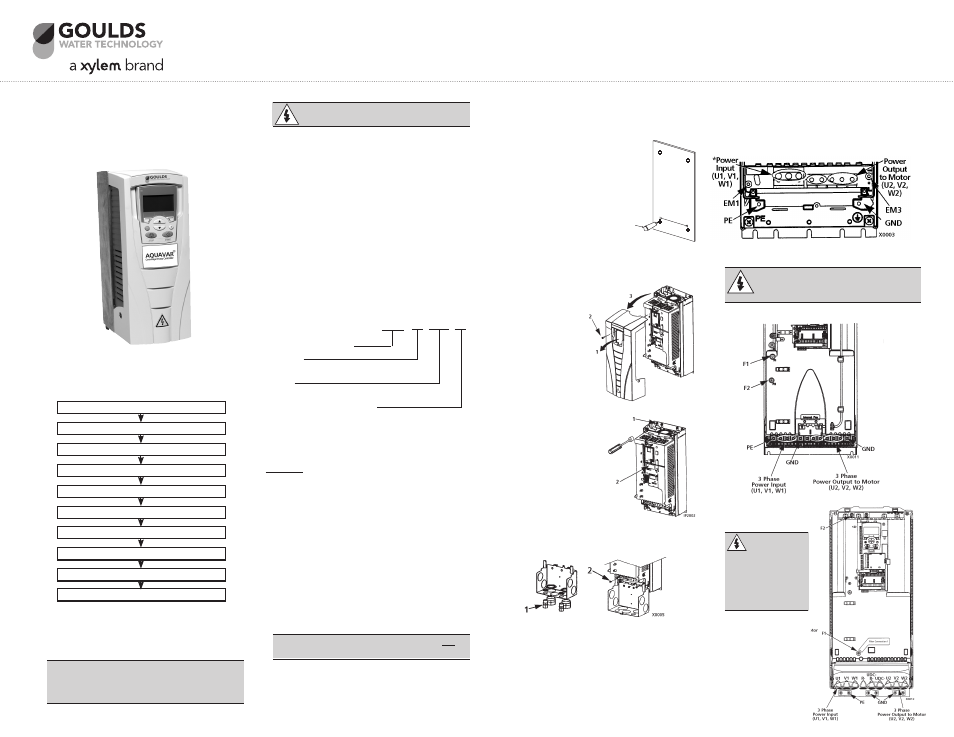

Remove the Front Cover

1. Remove the control panel

(display), if attached.

2. Loosen the

captive screw

at the top.

3. Pull near the

top to remove

the cover.

Mount the Drive

1. Position the

AQUAVAR and use

screws or bolts to

securely tighten all

four corners.

2. Attach a warning

sticker in the

appropriate language

on the inside plastic shell.

Install the Wiring

1. Install thin-wall conduit clamps (not

supplied) in the conduit/gland box.

2. Install conduit/gland box.

Wiring Power

1. Connect conduit runs to box.

2. Route input power and motor

wiring through conduits.

1

X0002

CPC 4 370 1

AQUAVAR

®

(Series)

Voltage

2 – 230 Volt

4 – 460 Volt

Amps

370 Amps

*See Technical Section

NEMA Enclosure Rating

1 – NEMA 1

2 – NEMA 12

3 – NEMA 3R with disconnect

4 – NEMA 4 with disconnect

5 – NEMA 3R without disconnect

6 – NEMA 4 without disconnect

Options

A – Field Bus Card

(Devicenet, Profibus)

* Consult factory for other options, if available.

Not all combinations may be available.

3. Strip wires.

4. Connect power, motor and

ground wires to the drive terminals.

See “Power Connections” in the

instruction manual.

Frame Sizes R1…R4

* Single phase input power must use U1, W1

and PE for wiring.

WARNING! For floating networks

remove screws at EM1 and EM3 on

Frame Sizes R1…R4.

Frame Size R5

Frame Size R6

WARNING!

For floating

networks remove

screws at F1 and

F2 on Frame Sizes

R5 or R6.

QUICKSTART GUIDE

AQCPCQR