6 maintenance – Analytical Industries Palm O2 IW Oxygen Analyzer User Manual

Page 9

14

15

6 Maintenance

Review Section 3 Safety Warnings and Section 7 Troubleshooting for

guidelines on servicing the devices.

6.1 Serviceability

Do not open the main compartment of the analyzer, as it contains no service-

able parts inside. Never attempt to repair the analyzer or sensor by yourself as

you may damage the analyzer which could void the warranty.

6.1.2 Cleaning / Reuse Instructions

Clean the device, oxygen sensor and accessories with a soft cloth dampened

with either water or mild isopropyl alcohol solution (70% isopropyl alcohol

solution in water), if necessary, before re-use. Allow the components to air-dry

after cleaning.

6.2 Battery Replacement

The Palm O2 Oxygen Analyzer is powered by two 1.5V AA alkaline batteries

with an approximate life of 13,000 hours.

A low battery indicator circuit monitors the battery supply

voltage and sends a signal directly to the LCD when the bat-

tery voltage reaches a preset level that activates the battery

symbol in the LCD.

The batteries are located the top section or front of the ana-

lyzer and secured by terminals mounted directly on the PCB

Assembly.

Procedure:

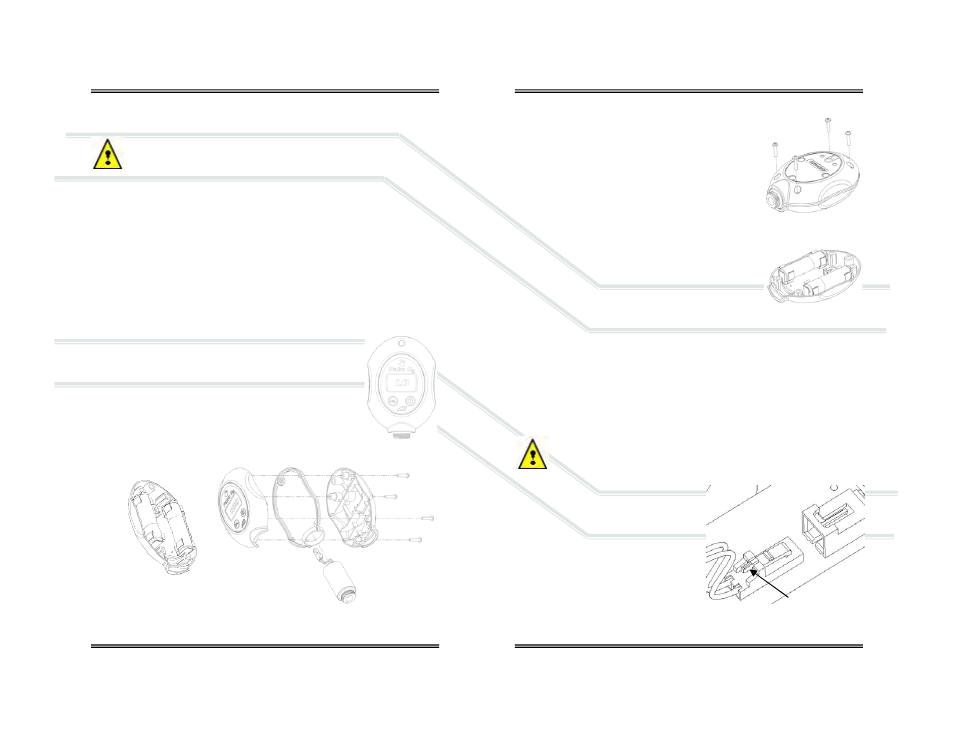

1. Open the enclosure: Remove the four (4) Phillips

screws from the rear of the enclosure, FIG 1.

2. Separate the enclosure and an place it on a flat

surface, FIG 2.

3. Remove the battery: Grasp the middle of a battery

and gently pull straight up.

4. Locate the positive (+) and negative (-) terminals

on the battery.

5. Assure the battery contacts are clean.

6. Align the battery’s positive (+) terminal with the

corresponding (+) battery symbol printed on the

PCB Assembly.

7. Install the battery: Align the battery over the termi-

nal clip mounted on the PCB Assembly and press

down until the battery snaps into place, FIG 2.

8. Repeat steps 3-7 with the remaining battery.

9. Reassemble the device as shown in section 6.4

10. Calibrate, see section 4.4, the device after replacing the batteries.

6.3 Oxygen Sensor Replacement - Standard Integral Sensor

The design of the electronics is intended for only the Analytical Industries Inc.

AII-11-75-PO2 or AII-11-75-PO2R Oxygen Sensors. Use of a different oxygen

sensor may result in an erroneous oxygen reading.

NEVER - Open the oxygen sensor or probe the sensing surface, refer

to Section 10 in the event the sensor should leak and someone comes

in contact with the electrolyte from inside the sensor.

Procedure - Standard Integral Sensor

1. See 6.2 step 1 above.

2. See 6.2 step 2 above.

3. Disconnect the oxygen sensor: Press

down on the latch arm, see arrow,

and pull back on the male connector

attached to the sensor from the fe-

male connector attached to the PCB

Assembly, FIG 3.

FIG 1

FIG 2

FIG 3