Analytical Industries Palm O2 IW Oxygen Analyzer User Manual

Page 8

12

Effect of Humidity

The analyzer is not affected by non-condensing relative humidity (RH). How-

ever, the addition of water vapor or moisture increases the total pressure

thereby diluting or decreasing the oxygen concentration of the gas mixture

resulting in a lower oxygen reading.

Effect of Condensation

Excessive condensation collecting on the sensing area or the electrical connec-

tions at the rear of the sensors can adversely impact the performance of elec-

trochemical sensors. Condensation blocks the diffusion path of oxygen into the

sensor and can reduce the oxygen reading to 00.0 if the condensation covers

the entire sensing area. Condensation on the electrical connections at the rear

of the sensor can affect oxygen readings. Remedy either situation by shaking

out the condensation and allowing the sensor to air dry.

Erroneously characterized in many instances as a sensor failure, excessive con-

densation is remedied by gently wiping away the condensation with a soft cloth

or simply allowing the sensor to air dry.

Effect of Electromagnetic Radiation

Tested over a 26 MHz to 1000 MHz electromagnetic field, the analyzer is sus-

ceptible at all frequencies tested except those between 930 and 990 MHz.

Never operate the analyzer near equipment capable of emitting high

levels of electromagnetic radiation. Do not continue to operate the

analyzer if the reading becomes unstable.

5.3 Calibration

Calibrating the analyzer during normal operation involves the same

precautions and procedures as those described in Sections 4.4 Start-up

Calibration with the same cautions to review Sections 3 Safety Warn-

ings and 5.2 Application Considerations.

5.4 Sampling

Assuming the START-UP TESTS are completed successfully the devices default

to the SAMPLING mode.

Never operate the analyzer if the reading is unstable or if a malfunction

is suspected. If calibration is required as indicated herein, do not pro-

ceed until the analyzer is calibration successfully.

13

5.4.1 Flowing Gas Streams

1. Place the sensing area of the sensor into the gas stream to be analyzed

upstream of any humidification equipment.

2. Assure that the flow rate of the gas stream does not exceed ten (10) liters

per minute. Exceeding ten (10) liters per minute generates backpressure.

3. Check the gas stream and particularly the mechanical connection for leaks

that dilute the gas stream with ambient air.

4. Assure there are no restrictions in the circuit downstream of the sensor

that could generate backpressure on the sensor.

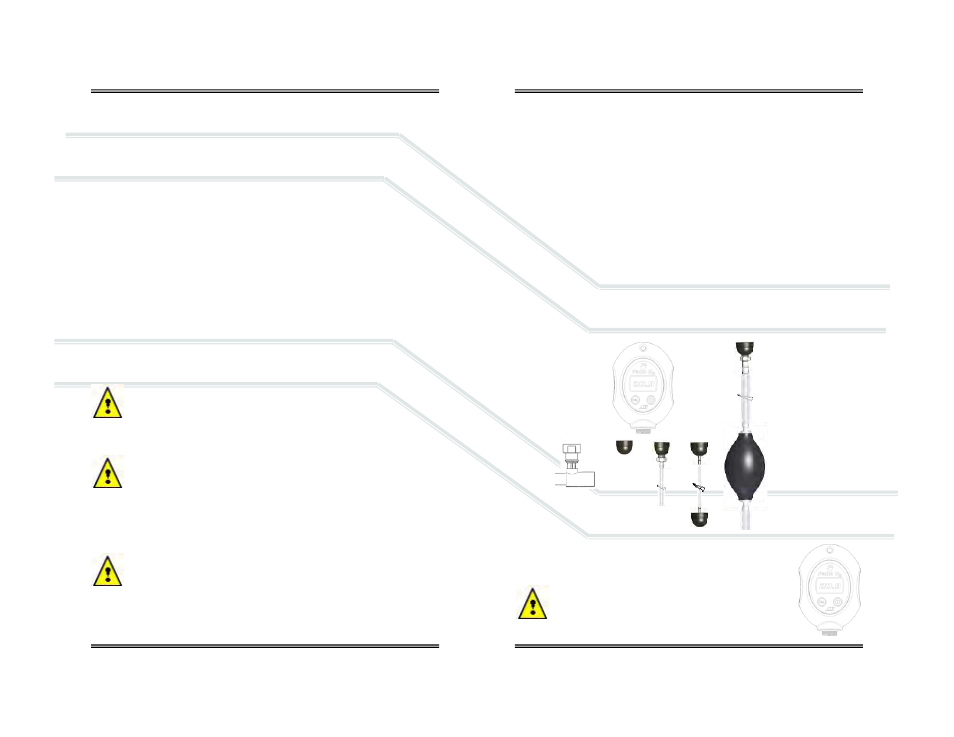

5. Select a means of flowing gas to the sensor, see below and Section 8.1.

6. Ensure the method selected (a) facilitates the movement of gas to and

from (sensor adapters include a vent hole) the sensing area of the sensor,

(b) forms a tight seal between the components and (c) limit the flow past

the sensor to a rate of 5-8 liters per minute or slightly crack a tank of

breathing air until it first hisses out.

7. Once the sensor is exposed to the gas stream allow approximately sixty

(60) seconds for the reading to stabilize as displayed by the LCD.

5.4.2 Static Atmospheres

Expose the sensing area of the sensor to the atmosphere allow-

ing approximately sixty (60) seconds for the reading to stabilize

and observe the reading displayed by the LCD.

If placing the entire sensor inside the controlled atmos-

phere review Section 5.2