Advanced instruments inc, Sampling – Analytical Industries GPR-15 AXP Trace PPM Oxygen Analyzer User Manual

Page 26

Advanced Instruments Inc.

26

11. Caution: Turning the actuator/potentiometer more the ½ turn recommended does not allow the electronics sufficient time

to keep pace with the adjustment. And since

adjustments are rarely made in one

consecutive turn – there is a real possibility

that the 2

nd

and 3

rd

part of the adjustment

could unknowingly be based on “values that

have not stabilized” thereby resulting in an

inaccurate calibration.

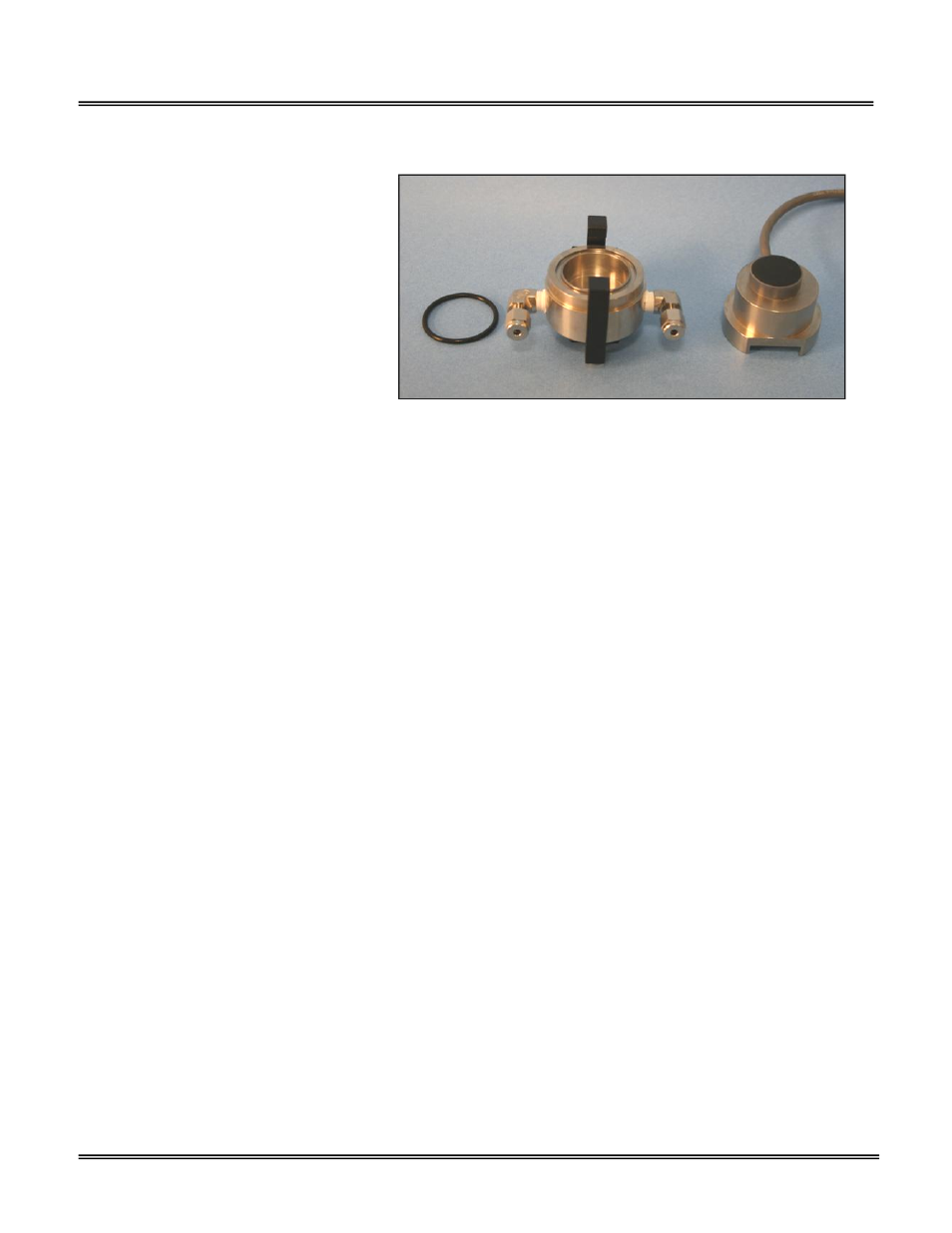

12. Reinstall the sensor as follows:

13. Place the sensor in the bottom section of

the sensor housing with the PCB facing up.

14. Place the upper section of the sensor

housing over the sensor.

15. Gently push the upper section downward

and rotate 90º to engage the clamp.

16. Finger tighten the clamp bolt and one full turn with the 5/16 wrench to compressed the o-ring seal.

17. Note: Manually turn the RANGE selector switch to follow the progress of the sensor’s recovery from exposure to air during

installation.

18. Begin sampling once the analyzer has reached the value of the purge gas.

Sampling

The sensor is exposed to sample gas that must flow or be drawn through the analyzer’s internal sample system. To ensure your

applications and gas sample are consistent with your expectations, review the Installation considerations in section 3.

Pico-Ion MS sensor: Slightly more sensitive to changes in flow rates but changes of 1-3 SCFH cause no appreciable change in

the oxygen reading. However, higher flow rates and/or sudden changes in flow rates can cause erratic readings or even

damage the sensor. A FLOW valve upstream of the sensor controls the flow rate of the sample gas which is displayed by the

flow indicator downstream of the sensor. A flow rate of 1 SCFH is recommended for optimum performance.

Galvanic ppm sensor: Flow rates of 1-5 SCFH cause no appreciable change in the oxygen reading. However, flow rates above 5

SCFH can generate erroneous oxygen readings. A FLOW valve upstream of the sensor controls the flow rate of the sample gas

which is displayed by the flow indicator downstream of the sensor. A flow rate of 2 SCFH is recommended for optimum

performance.

Galvanic percent sensors: Flow rates of 1-5 SCFH cause no appreciable change in the oxygen reading. However, flow rates

above 5 SCFH can generate erroneous oxygen readings. A FLOW METER with integral metering valve upstream of the sensor

controls the flow rate of the sample gas and displays the flow rate. A flow rate of 2 SCFH is recommended for optimum

performance.

Application Pressure - Positive:

A FLOW valve positioned upstream of the sensor controls the sample flow rate to the recommended flow rate. If necessary, a

pressure regulator (with a metallic diaphragm is recommended for optimum accuracy, the use of diaphragms of more

permeable materials may result in erroneous readings) upstream of the flow control valve should be used to regulate the inlet

pressure as specified in section 4.

Application Pressure - Atmospheric or Slightly Negative:

For accurate ppm range oxygen measurements, an optional integral sampling pump is positioned downstream of the sensor to

draw the sample from the process, by the sensor and out to atmosphere.

Caution: If the analyzer is equipped with an optional integral sampling pump (positioned downstream of the sensor),

completely open the FLOW valve (positioned upstream of the sensor) to avoid drawing a vacuum on the sensor and placing an

undue burden on the pump.

Review the Sample System discussion found in the Principle of Operation section at the beginning of section 5.