Hotpoint Ariston PH 750 T (AV) R-HA User Manual

Page 25

GB

25

Connecting a flexible jointless stainless steel pipe to

a threaded attachment

The gas supply pipe fitting is a threaded 1/2 gas cylindrical

male attachment.

These pipes must be installed so that they are never longer

than 2000 mm when fully extended. Once connection has

been carried out, make sure that the flexible metal pipe

does not touch any moving parts and is not compressed.

! Only use pipes and seals that comply with current national

regulations.

Checking the tightness of the connection

! When the installation process is complete, check the pipe

fittings for leaks using a soapy solution. Never use a flame.

Adapting to different types of gas

To adapt the hob to a different type of gas other than default

type (indicated on the rating plate at the base of the hob or

on the packaging), the burner nozzles should be replaced

as follows:

1. Remove the hob grids and slide the burners off their

seats.

2. Unscrew the nozzles using a 7 mm socket spanner, and

replace them with nozzles for the new type of gas (see

table 1 “Burner and nozzle characteristics”).

3. Reassemble the parts following the above procedure in

the reverse order.

4. Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Sticker are available from any of our Service Centres.

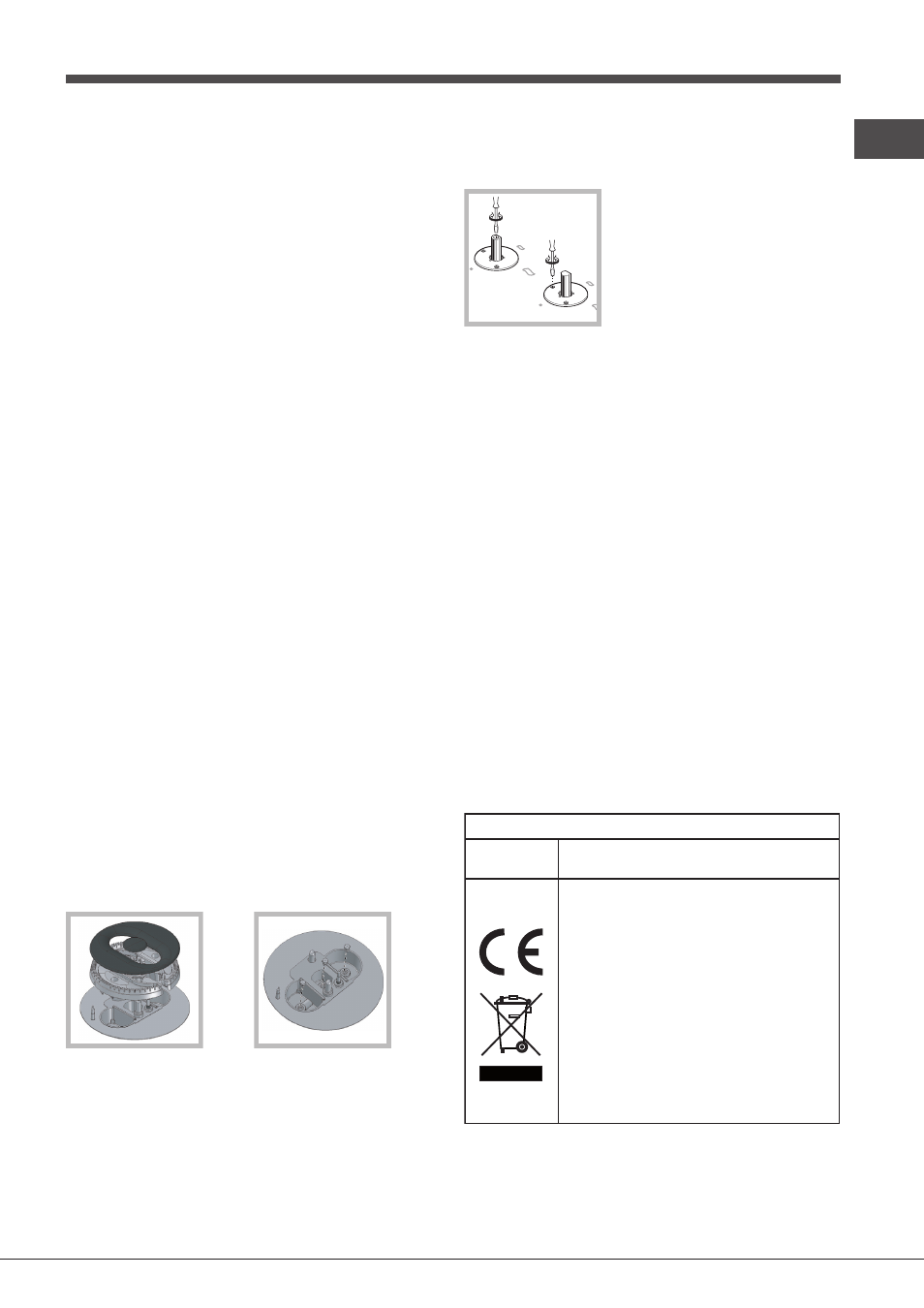

Replacing the nozzles on separate “double flame “

burners

1. remove the grids and slide the burners from their

housings. The burner consists of 2 separate parts (see

figure);

2. unscrew the burers with a 7 mm wrench spanner. The

internal burner has a nozzle, the external burner has

two (of the same size). Replace the nozzle with models

suited to the new type of gas (see table 1).

3. replace all the components by repeating the steps in

reverse order.

• Adjusting the burners’ primary air

Does not require adjusting.

• Setting the burners to minimum

1. Turn the tap to the low flame position;

2. Remove the knob and adjust

the adjustment screw, which is

positioned in or next to the tap pin,

until the flame is small but steady.

3. Having adjusted the flame to the required low setting,

while the burner is alight, quickly change the position

of the knob from minimum to maximum and vice versa

several times, checking that the flame does not go out.

4. Some appliances have a safety device (thermocouple)

fitted. If the device fails to work when the burners are set

to the low flame setting, increase this low flame setting

using the adjusting screw.

5. Once the adjustment has been made, replace the

seals on the by-passes using sealing wax or a similar

substance.

! If the appliance is connected to liquid gas, the regulation

screw must be fastened as tightly as possible.

! Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used. Stickers

are available from any of our Service Centres.

! Should the gas pressure used be different (or vary slightly)

from the recommended pressure, a suitable pressure

regulator must be fitted to the inlet pipe (in order to comply

with current national regulations).

Electrical

connections

DATA PLATE

see data plate

This appliance conforms to the following

European Economic Community directives:

- 2006/95/EEC dated 12/12/06 (Low

Voltage) and subsequent amendments

- 2004/108/EEC dated 15/12/04

(Electromagnetic Compatibility) and

subsequent amendments

- 93/68/EEC dated 22/07/93 and

subsequent amendments.

- 2009/142/EEC dated 30/11/09 (Gas) and

subsequent amendments.

- 2002/96/EC and subsequent

amendments.