Operation manual for digital deadbolt – Factory Direct Hardware Copper Creek HZE2630LF User Manual

Page 2

OPERATION MANUAL FOR DIGITAL DEADBOLT

EDA-33

A. DOOR &JAMB PREPARATION/LATCH INSTALLATION

B. INSTALLATION OF DEADBOLT ASSEMBLY

C. INSTALLATION OF RECEIVER MODULE

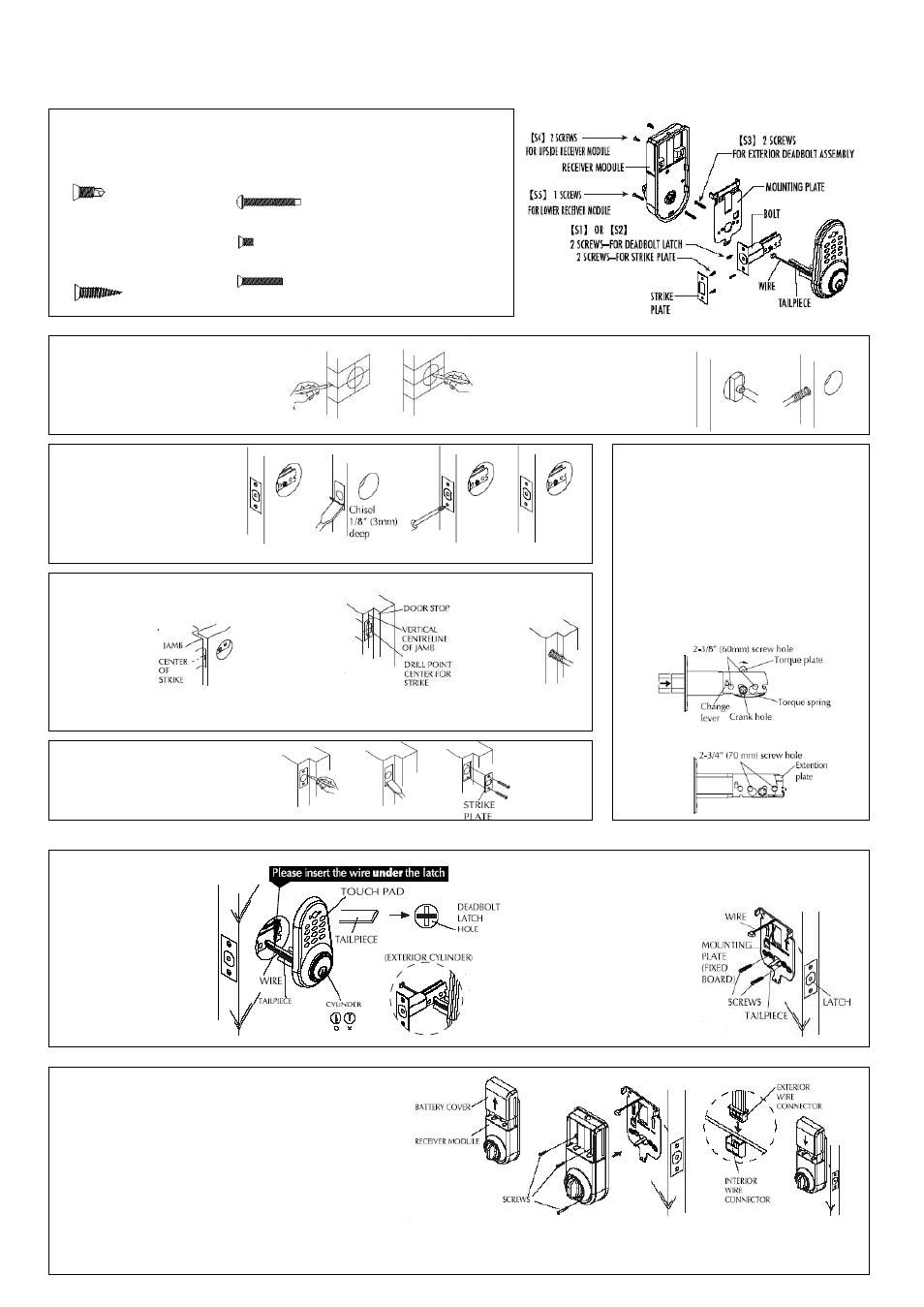

S1..FOR METAL DOORS

1/4”(6mm) 2 SCREWS-FOR DEADBOLT LATCH

1/4”(6mm) 2 SCREWS-FOR STRIKE PLATE

S2..FOR WOOD DOORS

3/4”(19mm) 2 SCREWS-FOR DEADBOLT LATCH

3/4”(19mm) 2 SCREWS-FOR STRIKE PLATE

S3..FOR DEADBOLT ASSEMBLY

FOR 5 PINS:

15/16”(24mm) 2 SCREWS-FOR 1-1/8”~1-3/8”(28mm~35mm) DOOR THICKNESS

1-1/4”(32mm) 2 SCREWS-FOR 1-3/8”~2”(35mm~51mm) DOOR THICKNESS

S4.5/16”(8mm) 2 SCREWS-FOR UPPER RECEIVER MODULE

S5. 1”(25mm) 1 SCREW-FOR LOWER RECEIVER MODULE

1. Mark Door

1) Use template provided to mark door for drilling 41”

(1044mm) from base of the door or 4”(101.6mm)

above door knob or lever center to center.

Use 2) Use the template to select backset 2-3/8”(60mm)

Or 2-3/4” (70mm).

2. Drill Holes

1) Bore 2-1/8”(54mm) hole through door face

from both sides of door to avoid damaging

door surface.

2) Drill 15/16”(24mm) or 1”(25.4mm) hole

through door edge.

3. Install Deadbolt Latch

1) Insert deadbolt latch into hole and mark

around the faceplate and screw holes.

2) Chisel recess for face plate.

3) Secure latch with screws.

4) Make sure the face plate of the latch

is even with edge of door.

4.Drill Holes And Install Strike Plate

1) Mark Jamb

a. Close door until deadbolt latch

touches door jamb.

Mark door jamb

as shown with

a pencil.

b. Center the strike plates

on the door jamb.

2) Mark Outline of Strike

a. Measure one half of

door thickness from

door stop and vertically

mark drill point center

for strike.

b. Place strike in position

and mark outline of

strike plate.

3) Drill Hole

a. Drill 1”(25.4mm)

hole in door

jamb

Caution: Hole in door jamb

must be drilled 1” (25.4mm)

deep.

5. Install Strike Plate

1) Chisel outline for strike plate 1.6”(4mm)

deep or until plate is flush with door jamb.

2) Install strike plate with screws.

ADJUST BACKSET FROM

2-3/8”(60mm) TO 2-3/4”(70mm)

A. Use provided torque blade or flat tip screwdriver

to rotate crank to retract the deadbolt to the

unlocked position.

B. Push the change lever up against the top.

Hold torque plate and torque spring and pull

the extention plate all the way out. Be sure

the 2-3/4”(70mm) screw hole is properly

aligned and change lever goes back to its

original position.

C. The deadbolt is now set for 2-3/4”(70mm)

backset.

1) Open door to ease installation.

2) Place exterior deadbolt assembly

on exterior of door,aligning

tailpiece horizontally through

deadbolt latch while passing the

wire under the deadbolt latch to

the interior side of the door.

Note:

1. Wire should be mounted under

the latch.

2. Tailpiece of exterior cylinder

should be inserted horizontally

through deadbolt latch hole first.

3) On interior side of door, place mounting

plate so the wire is routed up through

bridge in plate, and recess of

mounting plate is aligned with

center of large hole.

Note: Make sure mounting plate

is oriented with arrow pointing

upward.

4) Secure and fasten mounting plate

with screws (2) which engage with

threaded holes of exterior key cylinder.

Note: Ensure the mounting plate is

Positioned vertically.

1) Remove battery cover from receiver module by sliding cover upward.

2) Position receiver module over mounting plate so turnpiece engages with

tailpiece. Be sure the turnpiece is vertical in the unlocked position.

3) Check operation of the deadbolt by manually turning the

turnpiece or using the key. Bolt should extend and retract

freely. If bolt cannot be moved freely,the direction of

entry Switch is in the wrong place. Move receiver module

and turn the Entry Switch to the opposite direction.

Install again and check the operation of bolt.

4) Connect interior wire connector to exterior wire connector.

5) Secure receiver module to mounting plate,using the screws provided.

Do not over tighten screws, then put on Logo.

6) Install (4)

receiver module.