Factory Direct Hardware Von Duprin 9827EO4 User Manual

Page 4

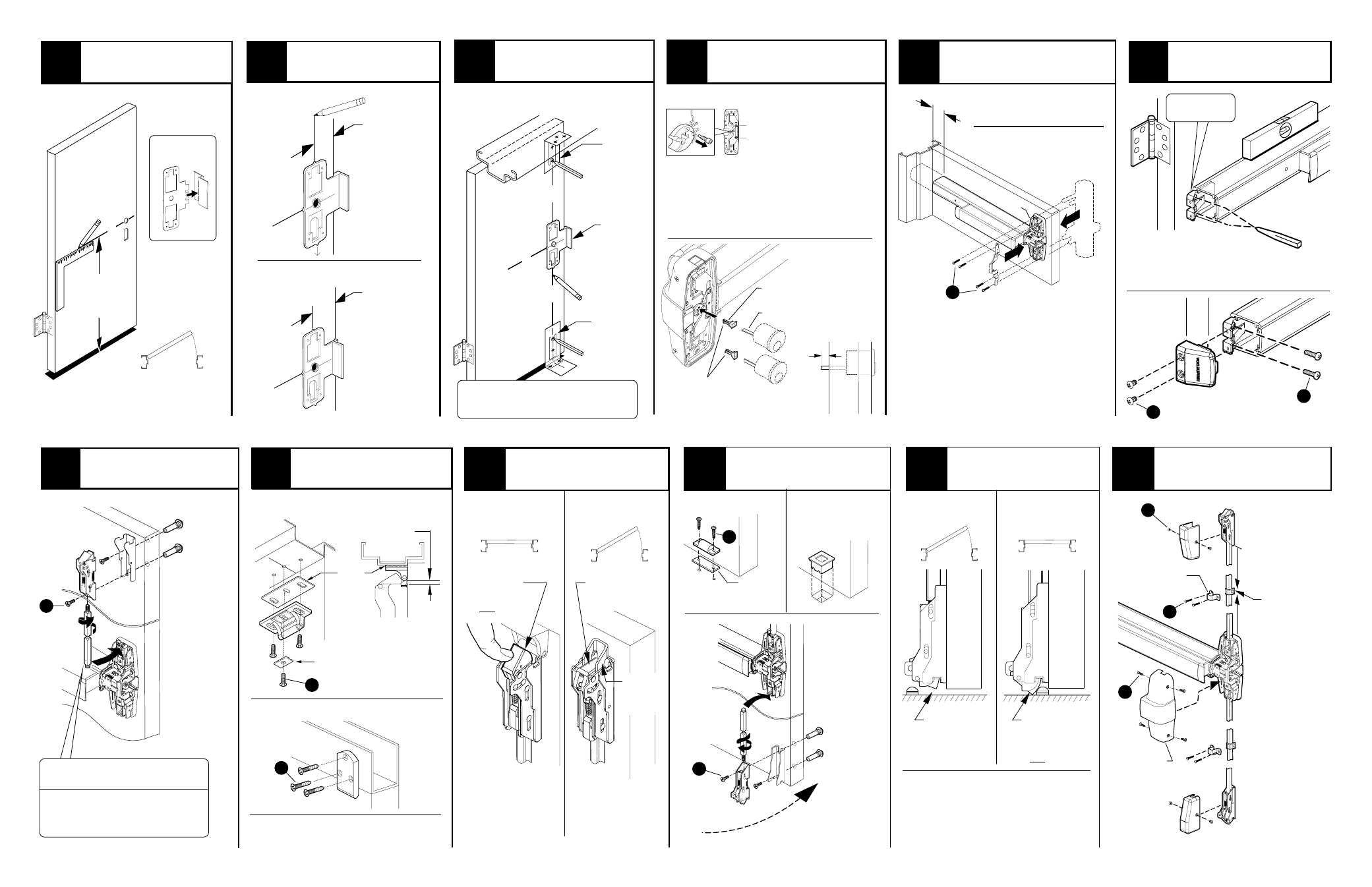

Shim

(as needed to

engage latch)

5

6

Install trim (if using) and

secure device center case

to door.

Install mounting bracket

and end cap.

7

Install top latch and rod.

Top

latch

Top rod

(longer of

the two)

If top rod is too long, see “cut

top rod” on page 6

Install top strike.

299/299F strike

8

#

325 sex

bolts

(required)

Strike plate

(299 only)

260U strike

3/16”

9

Install bottom strike,

latch, and rod.

11

Adjust bottom rod with

door open (top latch

retracted).

Open and close door a few times

and check for deadlatching when

door is closed

Readjust rods if needed

Adjust top rod (screw

rod into or out of latch)

until adjusted as shown.

9

10

248L-4 strike

304L strike

Grout strike

into floor

With door

closed:

With door

open:

Latch bolt

should clear floor

and not bind on

strike

With door

closed:

With door

open:

Bottom

latch

Bottom

rod

#325

sex bolts

(required)

Door open

(top latch retracted)

2

Align top and bottom

templates along center

line, and prepare door

.

3

Position template as shown

and mark vertical C.

Or flip template over for:

1

RHR shown

(LHR opposite)

Draw horizontal center

line (C ) and assemble

device template.

Bottom

template

CL

39-5/8”

To finished

floor

Shim

to 3/16”

as shown

L

Latch bolt

deadlocked

(will not push in)

Latch bolt stays

retracted

Release

trigger

extended

Latch bolt

should be

deadlocked

(will not push in)

If top rod is too short, see

“install rod extension”

on page 6

Secure

mounting

bracket

and end cap

Mounting

bracket flush

Level device

Mark and prepare 2

mounting holes

See “Preparation Chart” on page 3

for preparation information

Device

template

Install rod guides, and covers.

12

Latch

cover(2)

*Rod

guide (2)

Center

case

cover

Install at

midpoint of

each rod

4

5

*See “Preparation

Chart” on page 3

CL

CL

See “Preparation Chart” on page 3 for

drill, tap, and cut-out information

2-3/16”

Standard

backset

For 9927

single and

double

door

2-3/4”

backset

If using a

9927 with a

9975 mortise

device on a

double door

CL

CL

Center

case

See “Screw Chart”

on page 2 for screw

types and sizes

A

B

C

D

E

F

G

D

H

I

J

CL

CL

CL

Vertical

L

Remove blue film

Top

template

Plastic

template

See trim instructions for pull side door

preparation. Line X-X in trim instructions

is same as vertical device CL

Trim

(optional)

1-1/2” Minimum clearance

(with end cap removed)

if device is too long for

door, see “Cut Device”

on back cover

Cut tailpiece

if needed

1/2”

Door

surface

4

Tailpiece

Tailpiece guide

Rotate tailpiece

guide to match

tailpiece

If using an outside cylinder,

check NL drive screw and

install tailpiece guide.

When installing trim that has a

functional lever, knob, or thumb

piece AND an outside cylinder

to lock and unlock the trim,

remove NL drive screw from

back of device.

DO NOT remove NL drive

screw for the following trims:

NL, EO, DT, TP-2, L-2, and K-2.

With “BE” trim, device may

need rehanded. Look for

instructions on back of trim.

Note: When the

NL drive screw

is left in back of

device, the outside

cylinder will

function only

as a Night Latch.

NL drive screw

499F strike (for LBR Fire devices)

See instruction 911009