Teck, Electronic faucet - 591t series, 4" cast lavatory – Factory Direct Hardware Delta 591T1266 User Manual

Page 2: Operation, Commercial, Dsp–591t rev. d, Flowrate vs pressure, Front view side view, Hydro power, Hardwire with battery backup

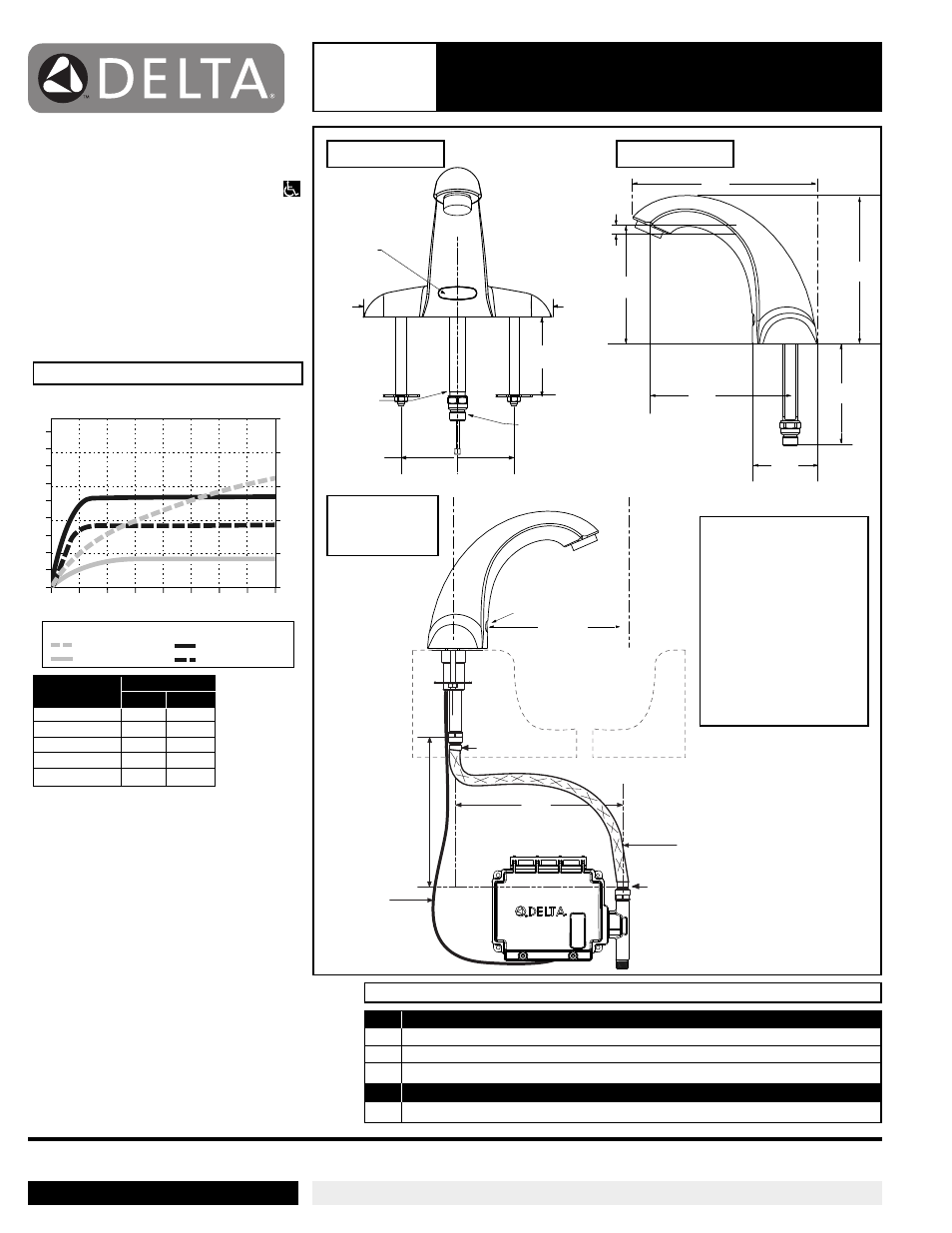

Electronic Faucet - 591T Series

4" Cast Lavatory

Delta reserves the right (1) to make changes in specifications and materials, and (2) to change or discontinue models, both without notice or obligation.

Dimensions are for reference only. See current full-line price book or www.specselect.com for finish options and product availability.

DSP–591T Rev. D

591T ELECTRONIC FAUCET OPTIONAL ACCESSORIES:

✔

TRANSFORMERS:

060704A

110 to 24VAC Class II 20VA (Up to 5 Electronic Valves)

060771A

110 to 24VAC Class II 40VA (Up to 10 Electronic Valves)

060772A

110 to 24VAC Class II 100VA (Up to 25 Electronic Valves)

✔

CORDS:

060690A

36" Cable Extension

Approvals:

• CSA certified

• Complies to ASME A112.18.1

• ADA Compliant and meets Handicapped

Accessibility Standard ASME A117.1

of less than 5 lbs. handle operating force.

• IAPMO listed

• Control Box Option 6 Mechanical Mixing

Valve CSA certified

• Control Box Option 8 Thermostatic Mixing

Valve CSA certified and meets ASSE 1016,

1017, 1070

(Contact Delta Representative for State and/or

Local Approvals.)

U.S. Patent # 6, 826, 455

OPERATION:

• Hands free (touchless) operation.

• Water flows when sensor is activated.

• Water flow stops upon de-activation of sensor.

• Auto shut-off feature that is selectable

between 15 to 75 seconds. Factory set to

45 seconds. Will reset once obstruction is

removed.

• Adjustable sensing distance 76 to 381mm

(3" to 15") factory set to 229mm (9") (+/– 1.0”)

• Low battery audible beep (for battery models

only). Will activate after faucet shuts off when

approximately 1500 cycles remain.

FLOWRATE vs PRESSURE

2.5

2

1.5

1

.5

0

0

0

1

2

3

4

5

6

7

8

9

10

20

30

40

50

60

70

80

Line Pressure (psig)

FLOW

(l/min.)

FLOW

(USGPM)

Spout Outlets

No. 3 & 4 Aerator

No. 2 Laminar Flow Outlet

No. 6 Flow Control Outlet

No. 5 Low Flow Outlet

Outlet Flowrates

Note: Measurements may vary ± 6mm (0.25'')

591T1250

Typical

Installation

92mm

(3.625")

58mm

(2.3")

127mm

(5.0")

107mm

(4.2")

165mm

(6.5")

135mm

(5.3")

D

Refer to www.specselect.com for individual models.

Product supplied as shown by solid lines. All items shown by dotted lines supplied by others.

CAST SPOUT “D”

OUTLET NO.

mm

in.

2

11

0.45

3

11

0.45

4

11

0.45

5

11

0.45

6

11

0.45

FRONT VIEW

SIDE VIEW

NOTE: For optimum performance of this product, we

recommend a system pressure between 20 and 80 PSI

static. This product will operate up toa maximum of

125 PSI static per ANSI and CSA requirements.

However, we do not recommend pressures above

80 PSI. Thermal expansion or leaking pressure reducing

valves may require use of expansion tanks or relief

valves to ensure your system never exceeds its

maximum intended pressure setting.

3/8" Compression

Connection

Sensor

168mm

(6.25")

3 Holes

22.2mm

(0.875") Dia.

51mm (2") MAX.

Deck Thickness

102mm

(4.0")

178mm

(7.0")

MAX.

331mm

(13.0")

MAX.

3/8"

Compression

Connection

Sensor

Cord

508mm (20.0")

Stainless Steel Hose

3/8"

Compression

Connection

Sensing Zone

228mm (9.0")

Default

Sensor

TECK

®

COMMERCIAL

HYDRO POWER

™

■

Add suffix “-HP” to Product

Number for Hydro Power

™

.

See DSP-HP for detailed

specification. Available on

Battery Powered #0 Control Box

and #2, 3 or 4 outlets only.

HARDWIRE WITH

BATTERY BACKUP

■

Add suffix “-BB” to Product

Number. See DSP-BB for

detailed specification.