3B Scientific Stirling Engine D User Manual

Page 5

5

1 3B NETlab™ program

U11310

1 Relative pressure sensor, ±100 hPa

U11321

1 Displacement sensor

U11371

1 DC power supply, 15 V, 1.5 A (230 V, 50/60 Hz)

U8521121-230

or

1 DC power supply, 15 V, 1.5 A (115 V, 50/60 Hz)

U8521121-115

•

Connect the relative pressure sensor to the

hose nozzle using silicone tubing.

•

Attach the base plate to the stand using the

knurled screw.

•

Screw the stem with the magnetic base into the

displacement sensor and place it on the base

plate.

•

Loosen the screw on the displacement sensor’s

pulley. Wind a thread once around the pulley

and lead it out of the recess placing a loop

around the screw. Use the screw to fix the

thread in place (see Fig. 8).

•

Attach one end of the thread to the hook of the

connector rod and suspend a weight from the

other end.

•

Use the suction pad to attach a second thread

to the base plate. Thread this over the groove

in the eccentric and use the other weight as a

load on the free end.

This load ensures that the pV diagram comes out

better.

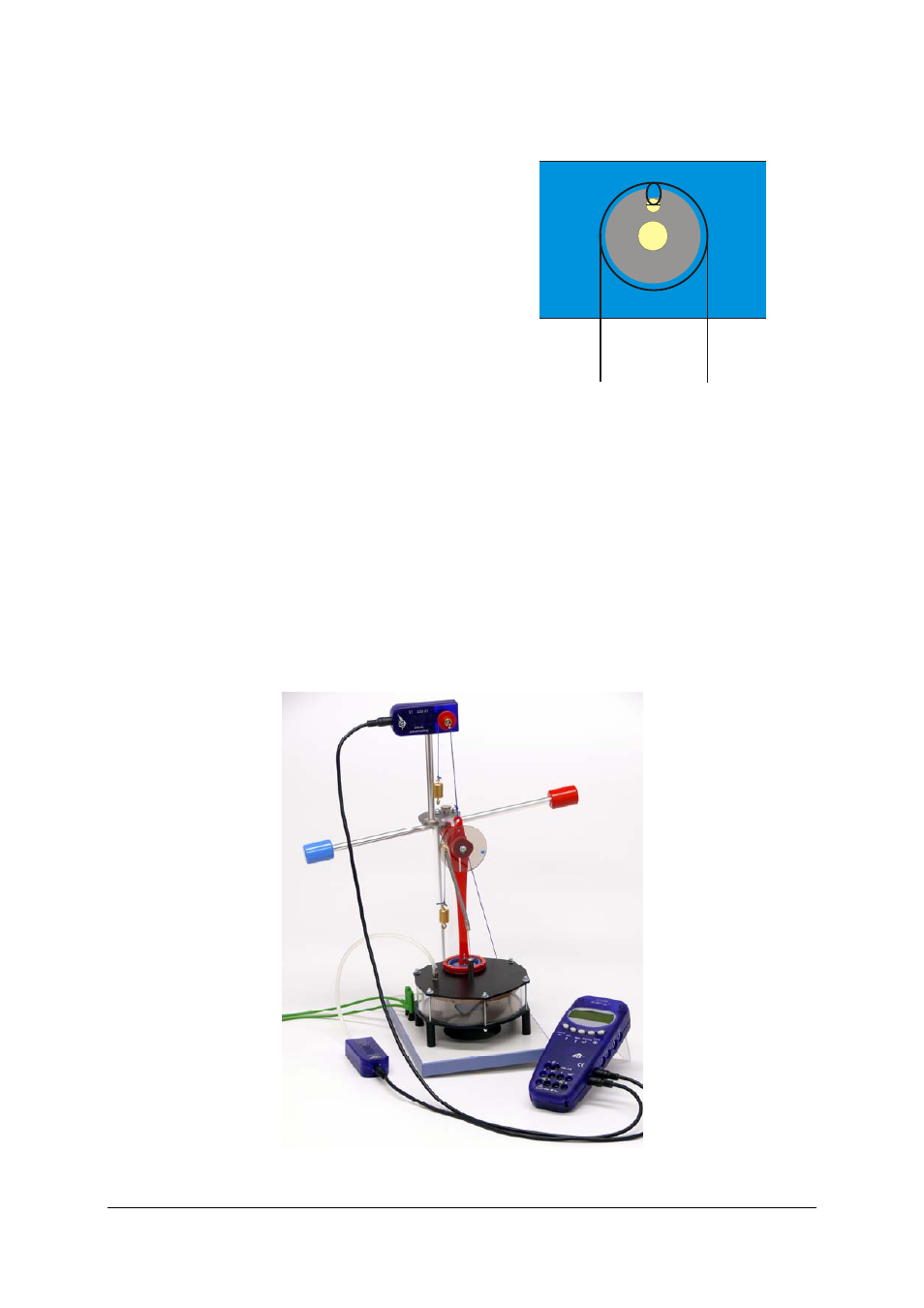

Fig. 8 Schematic illustration of how the thread is wound

around the pulley of the displacement sensor (U11371)

•

Connect the power supply to the heater plate

and set the voltage up to 12 V (1.5 A approx.).

•

Connect both sensors to the 3B NETlog™ inter-

face.

•

Run the software on a computer.

•

After the Stirling engine has heated up, start it

running by pushing the rotor in a clockwise di-

rection.

•

Start a measurement using the software and

evaluate the data.

Fig. 9 Experiment set-up for recording a pV diagram