3B Scientific Stirling Engine D User Manual

Page 4

4

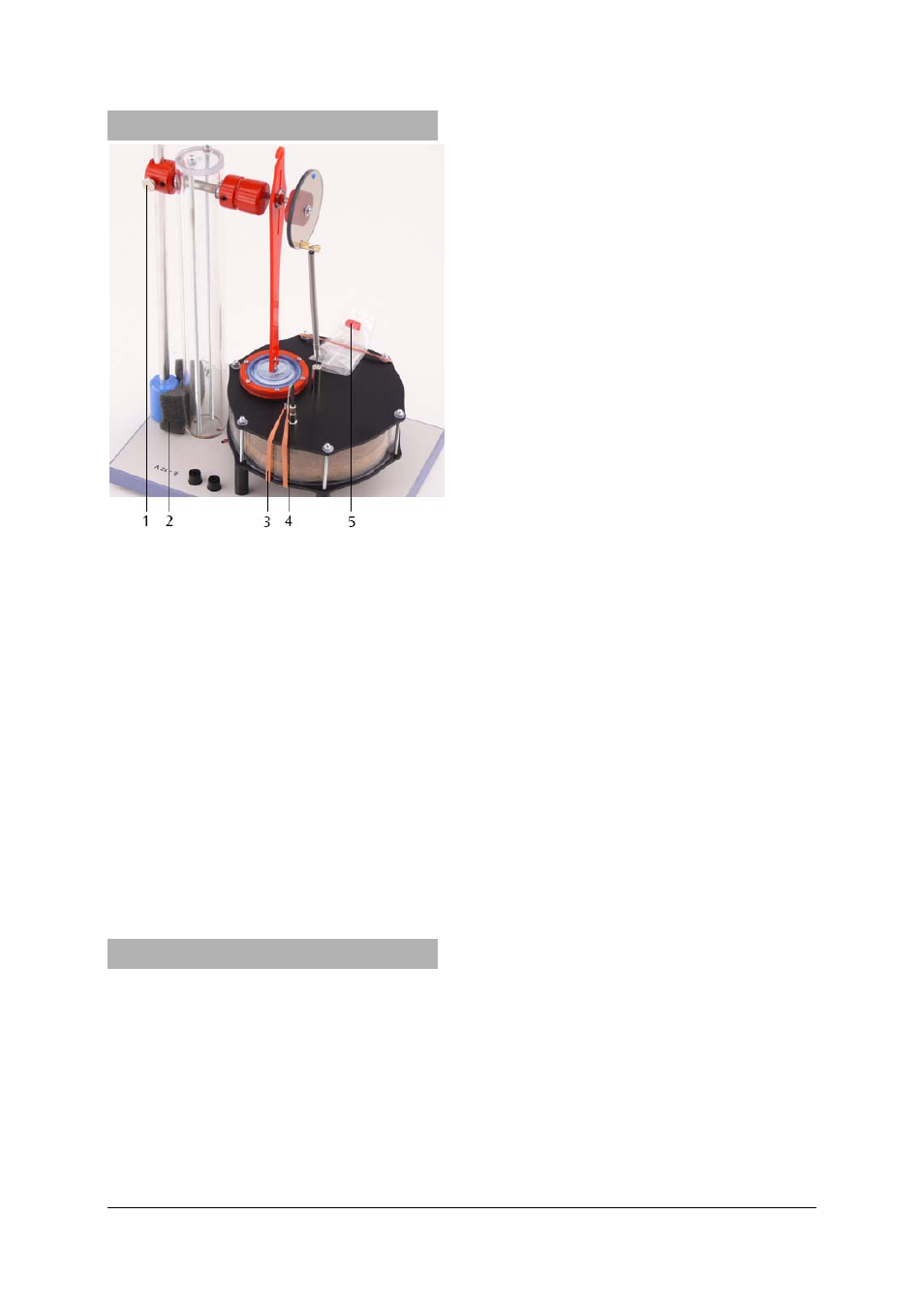

7. Getting the engine ready for use

Fig. 7 Stirling engine as secured for storage

•

Remove the rubber band (3) from the securing

hook (4) for the displacement piston and take

the hook out of the hose nozzle.

•

Seal off the hose nozzle with the red cap (5).

•

Remove the foam plastic block (2) between the

stand and the rotor weight.

•

Undo the securing screw (1), align the rotor

horizontally so that it is balanced and tighten

the screw back up again.

The engine is then ready for use.

The Stirling engine must not be transported unless

the displacement piston is secured.

•

To secure it, take the sealing cap of the hose

nozzle, put the securing hook back in and se-

cure it in place with the rubber band.

•

Secure the rotor as well.

8. Operation

8.1 Operation as a heat engine

8.1.1 Electric

heating

The following power supplies are recommended for

heating the Stirling engine electrically:

1 DC power supply, 15 V, 1.5 A (230 V, 50/60 Hz)

U8521121-230

or

1 DC power supply, 15 V, 1.5 A (115 V, 50/60 Hz)

U8521121-115

•

Connect the power supply to the pair of sockets

and set the heater voltage up to 12 V (1.5 A

approx.).

•

After heating for about one or two minutes,

start the engine by pushing the rotor clockwise

as seen from the front of the engine.

•

If the Stirling engine fails to keep moving of its

own accord, wait about a minute longer and

push the rotor round again.

The speed of the engine is nearly proportional to

the difference in temperature between the top

plate and the bottom plate and is thus largely de-

pendent on the heat supplied.

•

Reduce the heater voltage in steps down to

about 8 V and observe how the speed reduces.

8.1.2

Heating via a candle flame

•

Light a tea candle and place it on a heat-

resistant mat.

•

Place the Stirling engine over the candle so the

hole in the middle is over the flame.

•

Wait for several minutes until the lower plate

has heated up.

•

Push the rotor clockwise as seen from the front

of the engine.

•

If the Stirling engine fails to keep moving of its

own accord, wait about a minute longer and

push the rotor round again.

8.1.3

Heating via a lamp (spotlight)

•

Shine a light on the top plate from about 1 or 2

cm using a lamp with a 60-W bulb and a focus-

sed beam (spotlight). In this case it is the lower

plate that will cool the air in the displacement

cylinder.

•

Alternatively, the upper plate can be heated

via sunlight focused using a concave mirror.

•

Wait for about 8 to 10 minutes until the upper

plate has heated up.

•

Push the rotor anti-clockwise as seen from the

front of the engine.

•

If the Stirling engine fails to keep moving of its

own accord, wait about a minute longer and

push the rotor round again.

8.2 Recording a pV diagram

To record a pV diagram, the following pieces of

equipment are also required:

1 Supplementary set for Stirling engine D U8440455

1 3B NETlog™ unit (230 V, 50/60 Hz)

U11300-230

or

1 3B NETlog™ unit (115 V, 50/60 Hz)

U11300-115