3B Scientific Stirling Engine G User Manual

Page 3

3

5.3 Plotting a graph of pressure against volume

when the Stirling engine is being used as a

heat pump

Additional instruments needed:

DC Power supply 15 V, 1.5 A

U8521121-230

or

DC Power supply 15 V, 1.5 A

U8521121-115

3B NETlog

TM

U11300-230

or

3B NETlog

TM

U11300-115

3B NETlab

TM

U11310

Relative pressure sensor, ±1000 hPa

U11322

Displacement sensor

U11371

Sensor Holder for Stirling Engine G

U11372

•

Attach the holder for the sensor to the base plate

of the Stirling engine.

•

Fit the relative pressure sensor to the bottom of

the sensor holder and the displacement sensor

at the top with the printed sides of the sensors

both facing upwards.

•

Connect the nozzle marked “+” on the relative

pressure sensor to the nozzle on the working cyl-

inder of the Stirling engine by means of the hose

included with the sensor holder (U11372) (see

Fig. 4).

•

Screw the cap nut attached to the string (sup-

plied with the sensor holder) onto the thread of

the working piston, thread the string around the

displacement sensor pulley and attach a coil

spring to the threaded rod (a detailed descrip-

tion of how to attach the sensor to the sensor

holder is included in the instruction manual for

the sensor holder U11372).

•

Connect the pressure sensor to analog input A of

the 3B NETlog

TM

unit and the displacement sen-

sor to analog input B.

•

Connect a DC voltage source via the 4 mm sock-

ets.

•

Adjust the voltage (maximum 12 V) and operate

the Stirling engine with the switch in the “down”

position.

•

Run the 3B NETlab

TM

software, open the experi-

ment “Stirling engine G” and plot a graph of

pressure against volume.

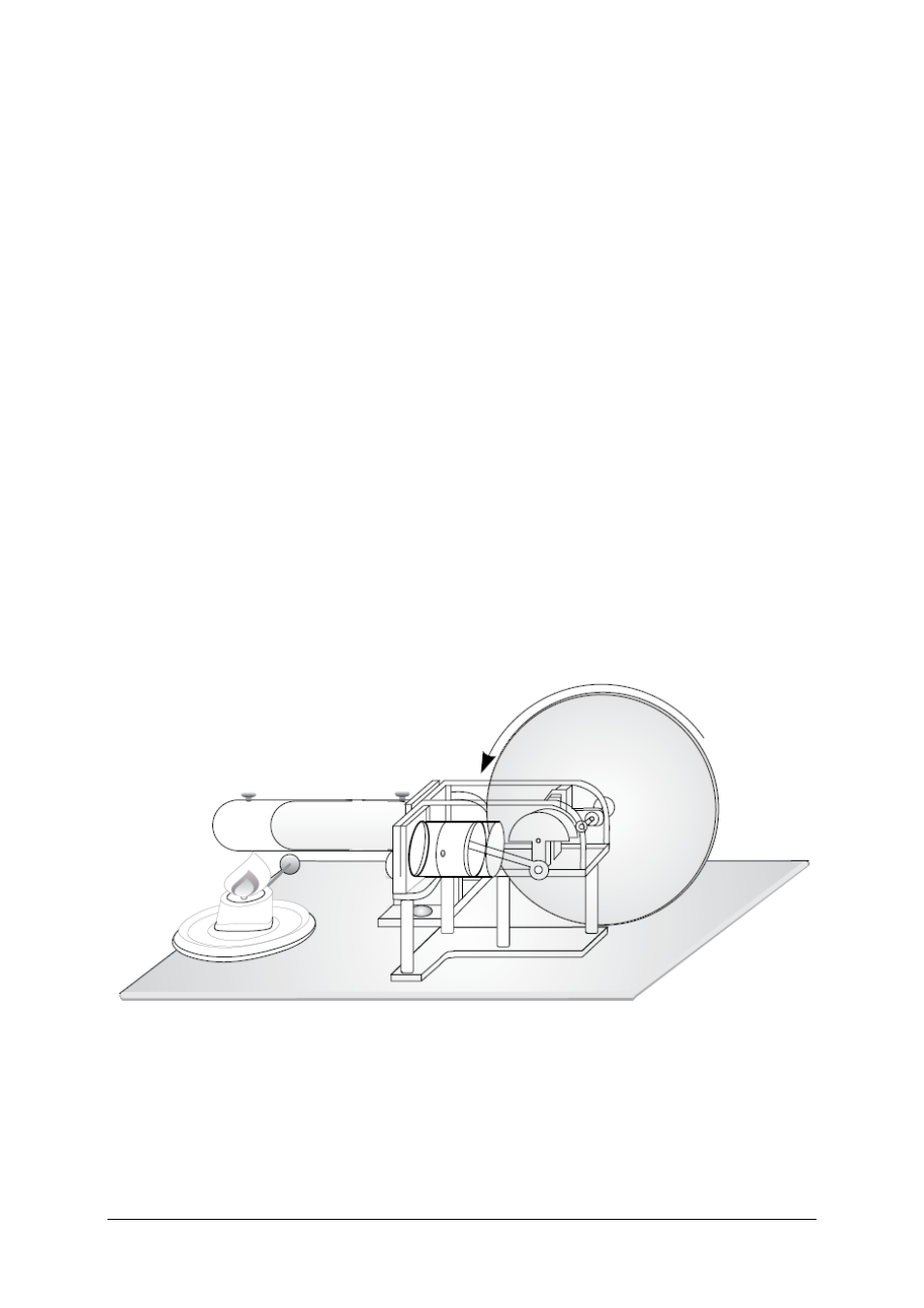

Fig.2

The Stirling motor as a heat engine