3B Scientific Heat Pump D (230 V, 60 Hz) User Manual

Page 2

2

Button Function

Zeit (Time)

displays the time / operating time of

the compresor (ED)

(changes when you press the button)

Strom (Cur-

rent)

displays the current consumption of

the compresor

Spannung

(Voltage)

displays the mains voltage

Leistung

(Power)

displays the momentary power con-

sumption

Energie

(Energy)

displays the energy, (unit: Wh)

Zeit (Time)

> 6s

Reset function for time, ED and

energy

The evaporator and condenser are constructed as

coils of copper piping and each is immersed in a

beaker filled with 2000 ml of water that serves as a

reservoir of heat in order to determine the quantity

of energy absorbed or emitted. Two additional ther-

mometers are required in order to measure the

temperature of the water in the beakers.

Two large manometers display the pressure of the

refrigerant in both heat exchangers. An overpressure

cut-out switch disconnects the heat pump from the

mains if the excess pressure reaches 15 bars.

So that the properties of the refrigerant in liquid and

gaseous states and the processes of conversion can

be viewed, the heat pump is equipped with viewing

windows. These allow the interior of the pump to be

seen and the state of the refrigerant to be observed

immediately after the evaporator or condenser.

The heat pump is available for two different mains

volatages. U8440600-230 is designed for 230 V (±10

%), 50 Hz mains supplies, while the U8440600-115

model is for 115 V (±10 %), 60 Hz supplies.

3. Technical data

Compressor power:

120 W, power consump

tion dependent on operat-

ing

state

Evaporator temperature: -10° C

Refrigerant (CFC-free):

R 134A (Tetrafluorethan, C

2

H

2

F

4

)

Boiling point:

-26° C

Manometer:

160 mm dia., evaporator

(suction intake) up to 9

bars; condenser (pressure

pipe) up to 24 bars

Overpressure cut-off:

disconnects compressor

from the mains at 15 bars

Power supply:

115 V, 60 Hz or 230 V, 50 Hz

Dimensions:

750 x 350 x 540 mm

3

Weight:

21 kg approx.

4. Operating principle

3.1 The processes in a heat pump circuit

In the most important and widely used type of heat

pump, the compressor heat pump, a substance in

the form of a liquid with a low boiling point circu-

lates in a closed loop. It passes through four differ-

ent processes. It is evaporated, compressed, con-

densed and then allowed to expand (see Fig. 1).

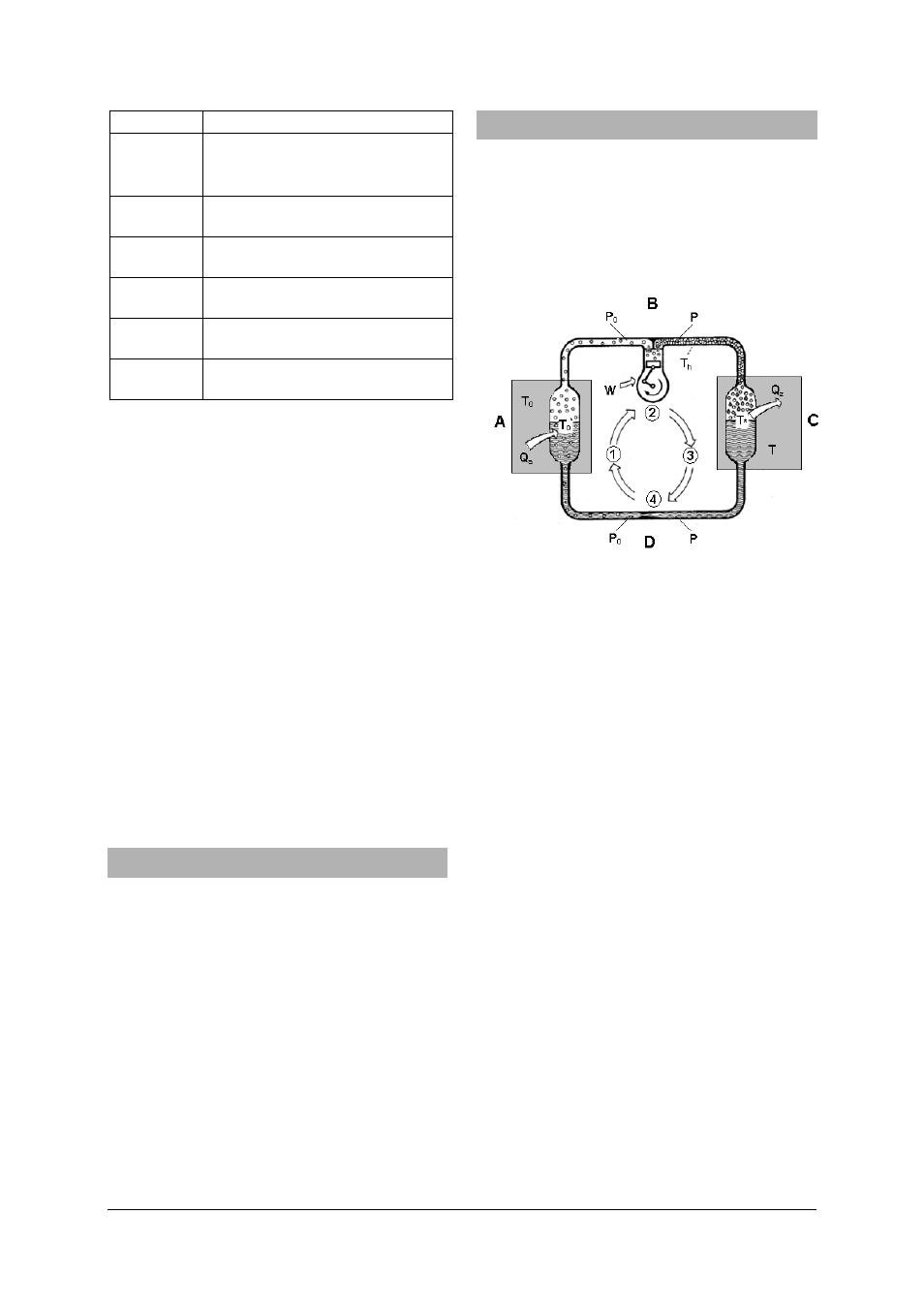

Fig. 1 Circulation in a heat pump

A Evaporator

B Compressor

C Condenser

D Expansion

valve

P

0

Low pressure in the evaporator segment from

the outlet of the expansion valve to the input

of the compressor

p

High pressure in the condenser segment from

the outlet of the compressor to the input of

the expansion valve

T

0

Temperature of the medium (soil, water, air)

surrounding the evaporator from which a

quantity of heat Q

a

is absorbed

T

Temperature of the medium (usually centrally

heated water), surrounding the condenser

which absorbs a quantity of heat Q

z

T

0

*

Boiling point of the refrigerant in the evapo-

rator

at

pressure

p

0

T

h

Temperature of the refrigerant vapour

after

compression

T*

Boiling point of the refrigerant in the con-

denser at pressure p

Q

a

Heat absorbed by the evaporator

Q

Z

Heat emitted by the condenser

W

Work performed by the compressor

3.1.1 Evaporation

In the evaporator the liquid refrigerant experi-

ences a low pressure p

0

. The temperature T

0

in

the medium surrounding the evaporator is higher

than the boiling point of the refrigerant T

0

* cor-

responding to the pressure p

0

. This tempera-