2 lubrication – R&M Materials Handling ELECTRIC CHAIN HOISTS LoadMate Chain Hoist LM 5 Stepless User Manual

Page 49

LoadMate

®

LM05 STEPLESS I&M/EN/11.30.2010

49/71

This document and the information contained herein, is the exclusive property of R&M Materials Handling, Inc., and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling, Inc.

Copyright © (2010) R&M Materials Handling, Inc. All rights reserved.

8.2 Lubrication

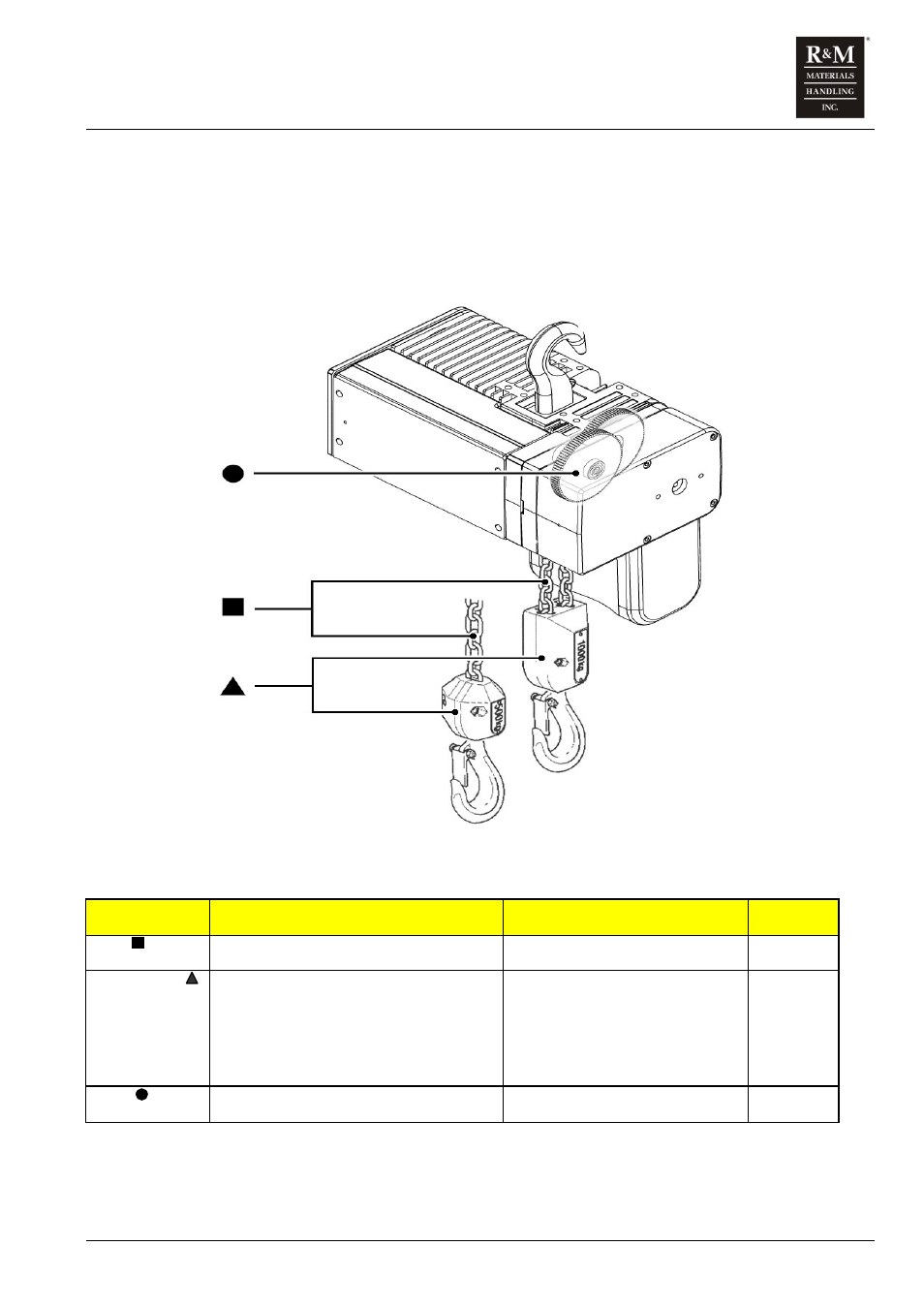

Figure 21. Lubrication Specifications

Table 7. Lubrication Specifications

LUBRICATION

POINT

SPECIFICATIONS

ACCEPTABLE LUBRICANTS

QUANTITY

Chain

Oil or Liquid grease

Chain lubricating fluid (Ceplattyn or

similar) EP-90

As required

Idler sprocket

Slide bearing +

bearing

Grease (without MoS2)

KP 2 (DIN 51 502)

Soap-based lithium

Approx. drip point + 500°F

Worked penetration 509-563°F

Operating temperature - 4°F - +266°F

BP: BP Energrease LS - EP 2

Esso: Unirex N2

Mobil: Mobilgrease HP

Shell: Shell Alvanio EP Grease 2

As required

Gears

Oil

Shell: Transaxle Oil 75W-90

0.6 liter

Open Wheel Gearing: EP1 Mobilux or equivalent.