MAX Power CT45-IP Electric Tunnel Thruster User Manual

Page 5

Manual CT35-IP & CT45-IP

April 2009

www.max-power.com

4

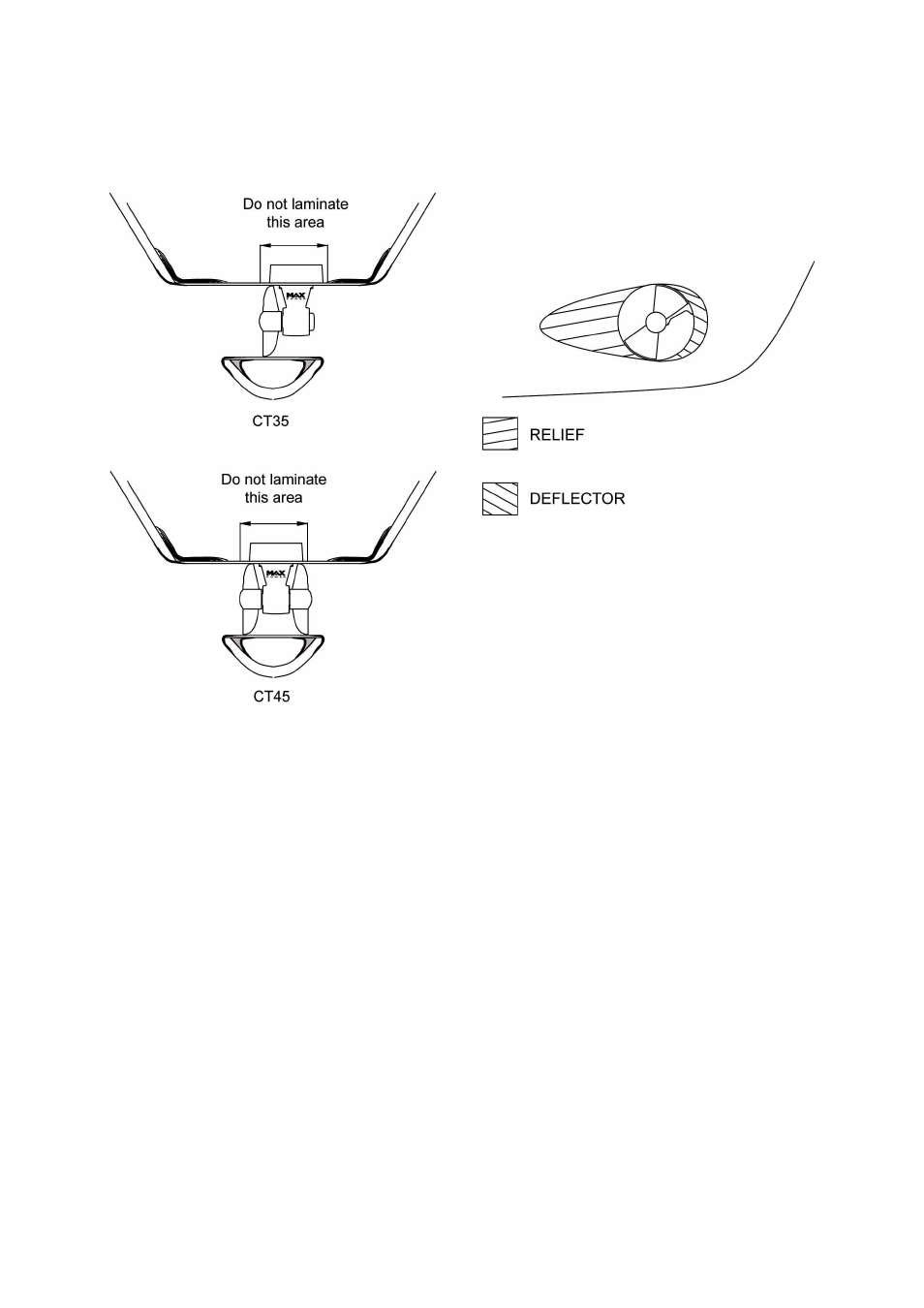

DO NOT LAMINATE THE AREA OF THE TUNNEL TO WHICH THE ELECTRICAL MOTOR

SUPPORT WILL BE FIXED.

3. COMPOSITE MOTOR SUPPORT AND DRIVE LEG

For the CT35-IP (Mono):

The propeller must be at the center of the tunnel. The motor support and the drive leg will

therefore not be centered in the tunnel.

For the CT45-IP (Duo):

The motor support and the drive leg will be centered in the tunnel.

For both models:

Locate and mark the intended position of the holes for the fixing screws and the leg hub.

You can use the motor support and the leg’s gasket to mark these holes.

In some cases it will be easier to mark and drill these holes BEFORE laminating the

tunnel.

After drilling, use the gasket to verify the holes’ axes and adjust them with a round file

where necessary.

These holes must be completely clean before inserting the screws.

Position the leg, the gasket (between the leg and the tunnel) and the motor support,

and then tighten the the two screws alternatively. Finally, mount the propeller(s) to control

the general alignment.

If the general set-up is correct, remove the propeller(s),the leg and the gasket.

Apply a thin coating of silicon grease or sealing compound to both sides of the gasket

(this must be resistant to hydrocarbons and water). Re-assemble all parts as before,