MAX Power CT45-IP Electric Tunnel Thruster User Manual

Page 4

Manual CT35-IP & CT45-IP

April 2009

www.max-power.com

3

2. TUNNEL

Once the final tunnel position has been determined and all dimensions have been

checked, mark the centre-point of the tunnel on both sides of the hull and drill holes of

8 –10 mm

∅

on either side.

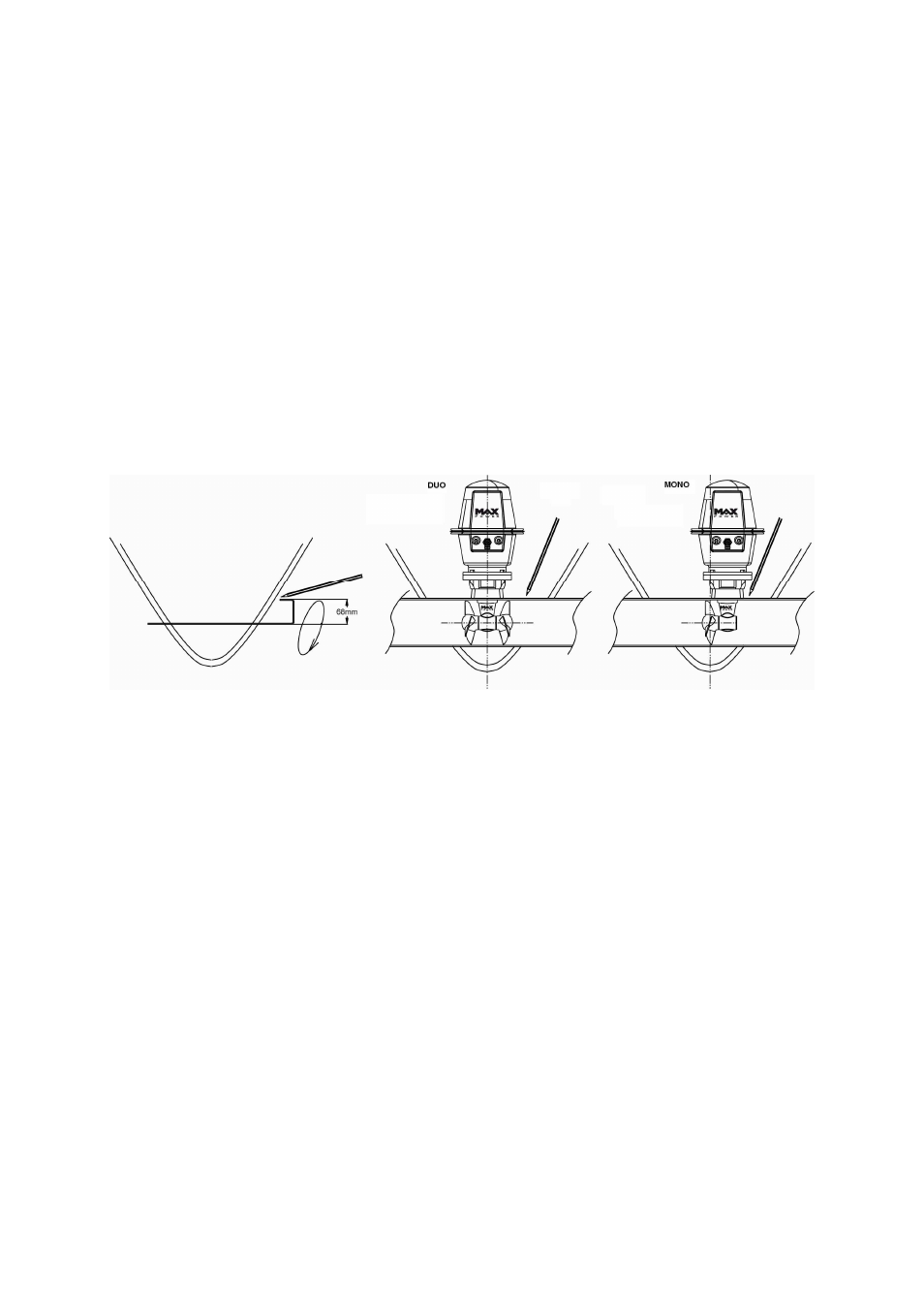

Using a metal rod, construct a compass with a 68mm radius. Insert through the holes and

trace the ellipses, as shown below.

After cutting the holes out following the elliptical guidelines, use an abrasive disc to

prepare the inside and outside surfaces of the hull for laminating (approx. 10 to 15cm

around the holes).

Position the tunnel in the hull, mark the positions of the different components, as well as

the areas that require laminating, then remove the tunnel. It is advisable to drill the tunnel

before laminating it into position. See section 3 "Composite Motor Support and Drive leg"

for more details.

Replace the tunnel. To secure its position apply reinforced fibreglass filler to all areas,

both inside and out, taking care to entirely fill the space between the hull and the tunnel.

Laminate using a minimum of 8 layers of ISOPHTALIC RESIN alternated with mat and

roving.

In difficult to access areas (i.e. under the tunnel), it is possible to only apply reinforced

filler.

Once the filler has set on the outside, finish with a waterproof under coat, followed by

sanding and application of a waterproof finish coat.

In order to optimise the flow of water whilst sailing, and to avoid turbulence due to the

tunnel, leave 1 to 4 cm of Finish these with several coats of reinforced filler in order to

obtain the required hydrodynamic lines.

Once all laminating work is complete, apply a watertight barrier.