Design procedure, Table 2. output voltage control – Rainbow Electronics MAX1672 User Manual

Page 8

MAX1672

Step-Up/Down DC-DC Converter

in QSOP Package

8

_______________________________________________________________________________________

__________________Design Procedure

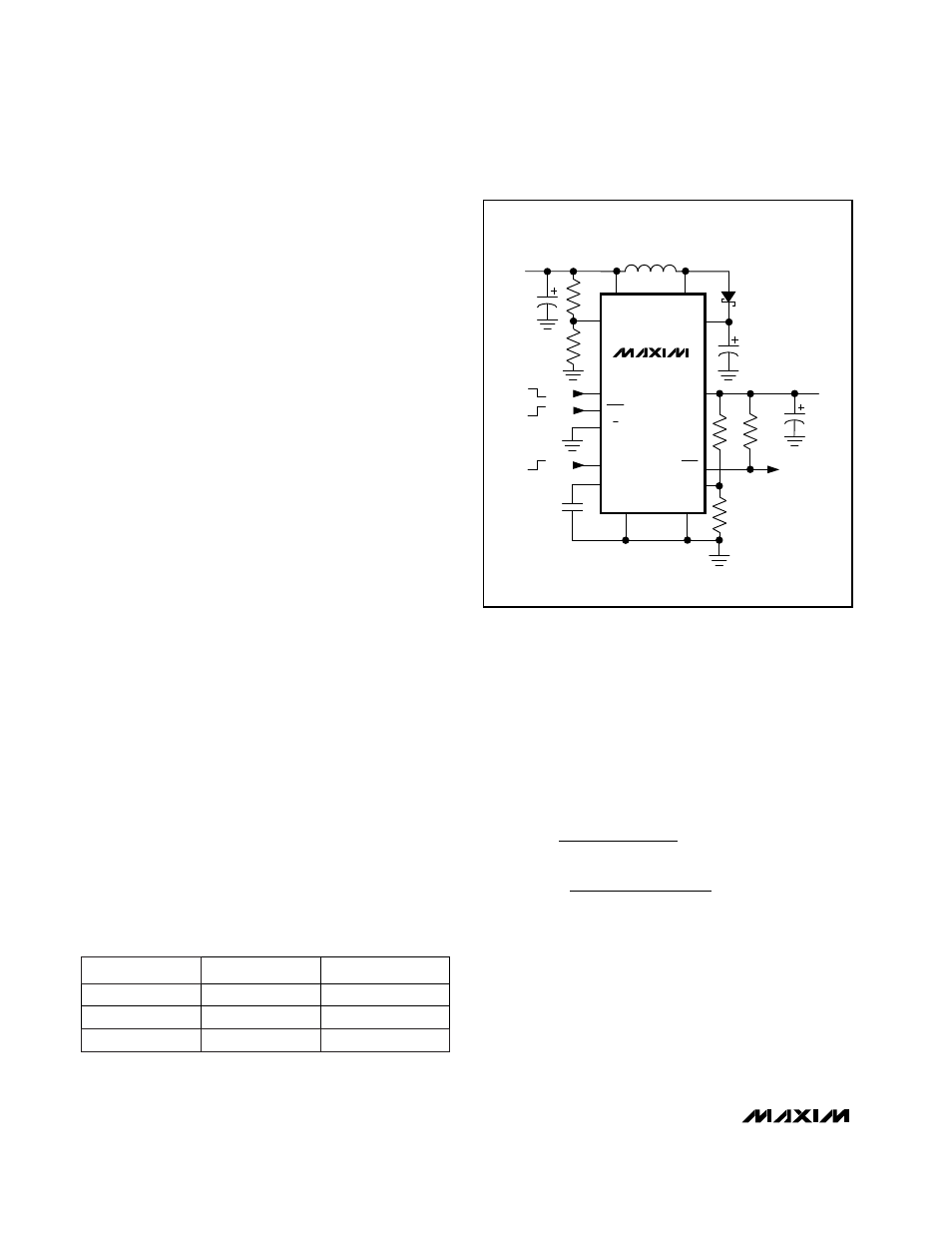

Output Voltage Selection

For fixed output voltages of 3.3V or 5V, connect 3/5 to

PS or GND and connect FB to GND (Table 2).

Alternatively, adjust the output voltage from 1.25V to

5.5V by connecting two resistors, R1 and R2 (Figure 2),

which form a voltage divider between OUT and FB.

Choose resistor values as follows:

R1 = R2[(V

OUT

/ V

REF

) -1]

where V

REF

= 1.25V. Since the input bias current at FB

has a maximum value of 50nA, R1 and R2 can be large

with no significant accuracy loss. Choose R2 in the

100k

Ω

to 270k

Ω

range and calculate R1 using the

above formula. For 1% error, the current through R1

should be at least 100 times FB’s bias current.

Whenever the voltage at FB exceeds 70mV above

GND, the state of the 3/5 pin is ignored. Connect 3/5 to

GND when adjusting V

OUT

with a resistor divider. Never

leave 3/5 unconnected.

Low-Battery Detection

The MAX1672 contains a comparator for low-battery

detection. If the voltage at PGI falls below V

REF

(typical-

ly 1.25V), the open-drain comparator output (PGO)

goes high. Hysteresis is typically 30mV. Set the low-

battery detector’s threshold with resistors R3 and R4

(Figure 2) using the following equation:

R3 = R4[(V

PGT

/ V

REF

) -1]

where V

PGT

is the desired threshold of the low-battery

detector and V

REF

= 1.25V. Since the input bias current

at PGI has a maximum value of 50nA, R3 and R4 can

be large to minimize input loading with no significant

accuracy loss. Choose R4 in the 100k

Ω

to 270k

Ω

range

and calculate R3 using the above formula. For 1%

error, the current through R3 should be at least 100

times PGI’s bias current.

The PGO output is open-drain and should be pulled

high with external resistor R5 for normal operation. If the

low-battery comparator is not used, connect PGI and

PGO to GND.

Inductor Selection

A 10µH inductor performs well in most MAX1672 appli-

cations. Smaller inductor values typically offer a smaller

physical size for a given series resistance, but may

increase switching losses. Larger inductor values

exhibit higher output current capability and larger phys-

ical dimensions for a given series resistance. For opti-

mum performance, choose an inductor value from

Table 3 or by using the following equation:

where I

LIM

is the peak switch-current limit, which is

0.8A for I

LIM

= PS and 0.5A for I

LIM

= GND.

The inductor’s incremental saturation current rating

should also be greater than the peak switch-current

limit. However, it is generally acceptable to bias most

inductors into saturation by as much as 20% with slight-

ly reduced efficiency. The inductor’s DC resistance sig-

nificantly affects efficiency. See Tables 4 and 5 for a list

of suggested inductors and suppliers.

V

+ V

I

V

+ V

I

OUT

DIODE

LIM

IN(min)

SWITCH

LIM

(

)

<

<

(

)

t

L

t

OFF

ON

2

(max)

MAX1672

IN

ONA

PGI

ONB

OFF

ON

C3

0.1

µ

F

C1

100

µ

F

C2

100

µ

F

R2

R1

R5

1M

C4

4.7

µ

F

R3

R4

L1

10

µ

H

PGND

GND

PS

1.25V TO

5.5V OUTPUT

INPUT

1.8V TO 11V

LOW-BATTERY-

DETECTOR

OUTPUT

OUT

PG0

FB

REF

LX

OFF

3/5

ILIM

0.8A

ON

0.5A

Figure 2. Adjustable Output Voltage Configuration

Table 2. Output Voltage Control

FB

V

OUT

(V)

0

GND

+5

1

GND

+3.3

3/

5

5

X

>70mV

+1.25 to +5.5