Design procedure, Table 1. protection features – Rainbow Electronics MAX8575 User Manual

Page 8

MAX8570–MAX8575

High-Efficiency LCD Boost

with True Shutdown

8

_______________________________________________________________________________________

Design Procedure

Inductor Selection

Smaller inductance values typically offer smaller physi-

cal size for a given series resistance or saturation cur-

rent. Circuits using larger inductance values may

provide more output power. The inductor’s saturation

current rating should be greater than the peak switch-

ing current. Recommended inductor values range from

10µH to 100µH.

Selecting the Current Limit

The peak LX current limit (I

LX(MAX)

) required for the

application is calculated from the following equation:

where P

OUT(MAX)

is the maximum output power

required by the load and V

BATT(MIN)

is the minimum

supply voltage used to supply the inductor (this is V

CC

unless a separate supply is used for the inductor). The

IC current limit must be greater than this calculated

value. See the Selector Guide on page 1 for selecting

the IC with the correct current limit.

Diode Selection

The high switching frequency of up to 800kHz requires

a high-speed rectifier. Schottky diodes are recom-

mended due to their low forward-voltage drop. To

maintain high efficiency, the average current rating of

the diode should be greater than the peak switching

current. Choose a reverse breakdown voltage greater

than the output voltage.

Capacitors

Small ceramic surface-mount capacitors with X7R or

X5R temperature characteristics are recommended

due to their small size, low cost, low equivalent series

resistance (ESR), and low equivalent series inductance

(ESL). If nonceramic capacitors are used, it is important

that they have low ESR to reduce the output ripple volt-

age and peak-peak load-transient voltage.

For most applications, use a 1µF ceramic capacitor for

the output and V

CC

bypass capacitors. For SW or the

inductor supply, a 4.7µF or greater ceramic capacitor

is recommended.

I

P

V

P

V

s

P

L

LX MAX

OUT MAX

BATT MIN

OUT MAX

BATT MIN

OUT MAX

(

)

(

)

(

)

(

)

(

)

(

)

.

.

≥

Ч

+

Ч

+ µ ×

1 25

1 25

3

2

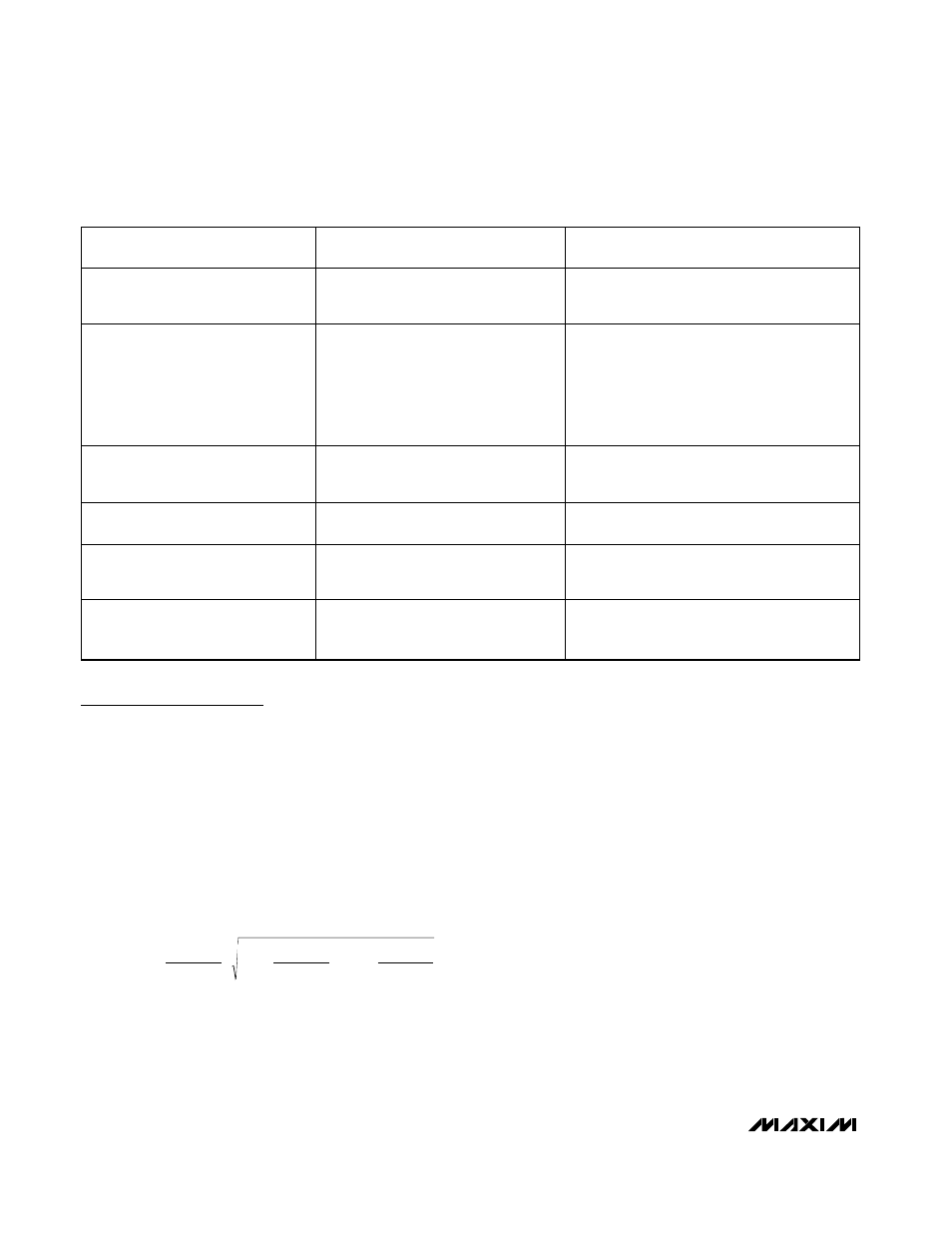

COMMON APPLICATION FAULTS

RESULT WITH COMPETING

STEP-UP CONVERTERS

RESULT WITH MAX8570 FAMILY

OUT to FB resistor missing or

disconnected.

OUT voltage rises until the output

capacitor is destroyed and/or

downstream components are damaged.

Converter stops switching.

Output cap missing and FB floating.

OUT voltage rises until the output

capacitor is destroyed and/or

downstream components are damaged.

LX may boost one or two times before the FB

voltage exceeds the trip point. In the rare case

where the capacitive loading and external

loading on OUT is small enough that the energy

in one cycle can slew it more than 50V, the

internal MOSFET will clamp between 35V and

70V (nondestructively).

FB shorted to GND.

OUT voltage rises until the output

capacitor is destroyed and/or

downstream components are damaged.

Converter stops switching and OUT is resistively

loaded to GND.

Diode missing or disconnected.

Diode reverse polarity.

Inductor energy forces LX node high,

possibly damaging the internal switch.

OUT is resistively loaded to GND and the

converter stops switching.

FB node floating.

Unpredictable, possibly boosting output

voltage beyond acceptable design

range.

FB node driven above its regulation point, the

converter stops switching, and OUT is resistively

loaded to GND.

OUT shorted to ground.

Current ramps up through inductor and

diode, generally destroying one of the

devices.

True off-switch detects short, opens when

current reaches pMOS current limit, and restarts

soft-start. This protects the inductor and diode.

Table 1. Protection Features