Rainbow Electronics MAX6690 User Manual

Page 8

MAX6690

2°C Accurate Remote/Local Temperature

Sensor with SMBus Serial Interface

8

_______________________________________________________________________________________

measure ambient temperature; when measuring local

temperature, it senses the temperature of the PC board

to which it is soldered. The leads provide a good ther-

mal path between the PC board traces and the

MAX6690’s die. Thermal conductivity between the

MAX6690’s die and the ambient air is poor by compari-

son. Because the thermal mass of the PC board is far

greater than that of the MAX6690, the device follows

temperature changes on the PC board with little or no

perceivable delay.

When measuring temperature with discrete remote sen-

sors, the use of smaller packages, such as SOT23s,

yields the best thermal response times. Take care to

account for thermal gradients between the heat source

and the sensor, and ensure that stray air currents

across the sensor package do not interfere with mea-

surement accuracy. When measuring the temperature

of a CPU or other IC with an on-chip sense junction,

thermal mass has virtually no effect; the measured tem-

perature of the junction tracks the actual temperature

within a conversion cycle.

Self-heating does not significantly affect measurement

accuracy. Remote-sensor self-heating due to the diode

current source is negligible. For the local diode, the

worst-case error occurs when autoconverting at the

fastest rate and simultaneously sinking maximum cur-

rent at the

ALERT output. For example, at an 8Hz rate

and with

ALERT sinking 1mA, the typical power dissi-

pation is V

CC

x 450µA + 0.4V x 1mA. Package theta J-

A is about 150°C/

Ω, so with V

CC

= 5V and no copper

PC board heat sinking, the resulting temperature rise is:

∆T = 2.7mW x 150°C/W = 0.4°C

Even with these contrived circumstances, it is difficult

to introduce significant self-heating errors.

ADC Noise Filtering

The ADC is an integrating type with inherently good

noise rejection, especially of low-frequency signals such

as 60Hz/120Hz power-supply hum. Micropower opera-

tion places constraints on high-frequency noise rejection;

therefore, careful PC board layout and proper external

noise filtering are required for high-accuracy remote

measurements in electrically noisy environments.

High-frequency EMI is best filtered at DXP and DXN with

an external 2200pF capacitor. This value can be

increased to about 3300pF (max), including cable

capacitance. Capacitance >3300pF introduces errors

due to the rise time of the switched current source.

Nearly all noise sources tested cause the ADC measure-

ments to be higher than the actual temperature, typically

by +1°C to +10°C, depending on the frequency and

amplitude (see Typical Operating Characteristics).

PC Board Layout

1) Place the MAX6690 as close as practical to the

remote diode. In a noisy environment, such as a

computer motherboard, this distance can be 4in to

8in (typ) or more, as long as the worst noise

sources (such as CRTs, clock generators, memory

buses, and ISA/PCI buses) are avoided.

2) Do not route the DXP-DXN lines next to the deflec-

tion coils of a CRT. Also, do not route the traces

across a fast memory bus, which can easily intro-

duce +30°C error, even with good filtering.

Otherwise, most noise sources are fairly benign.

3) Route the DXP and DXN traces in parallel and in

close proximity to each other, away from any high-

voltage traces, such as +12VDC. Leakage currents

from PC board contamination must be dealt with

carefully since a 20M

Ω leakage path from DXP to

ground causes about +1°C error.

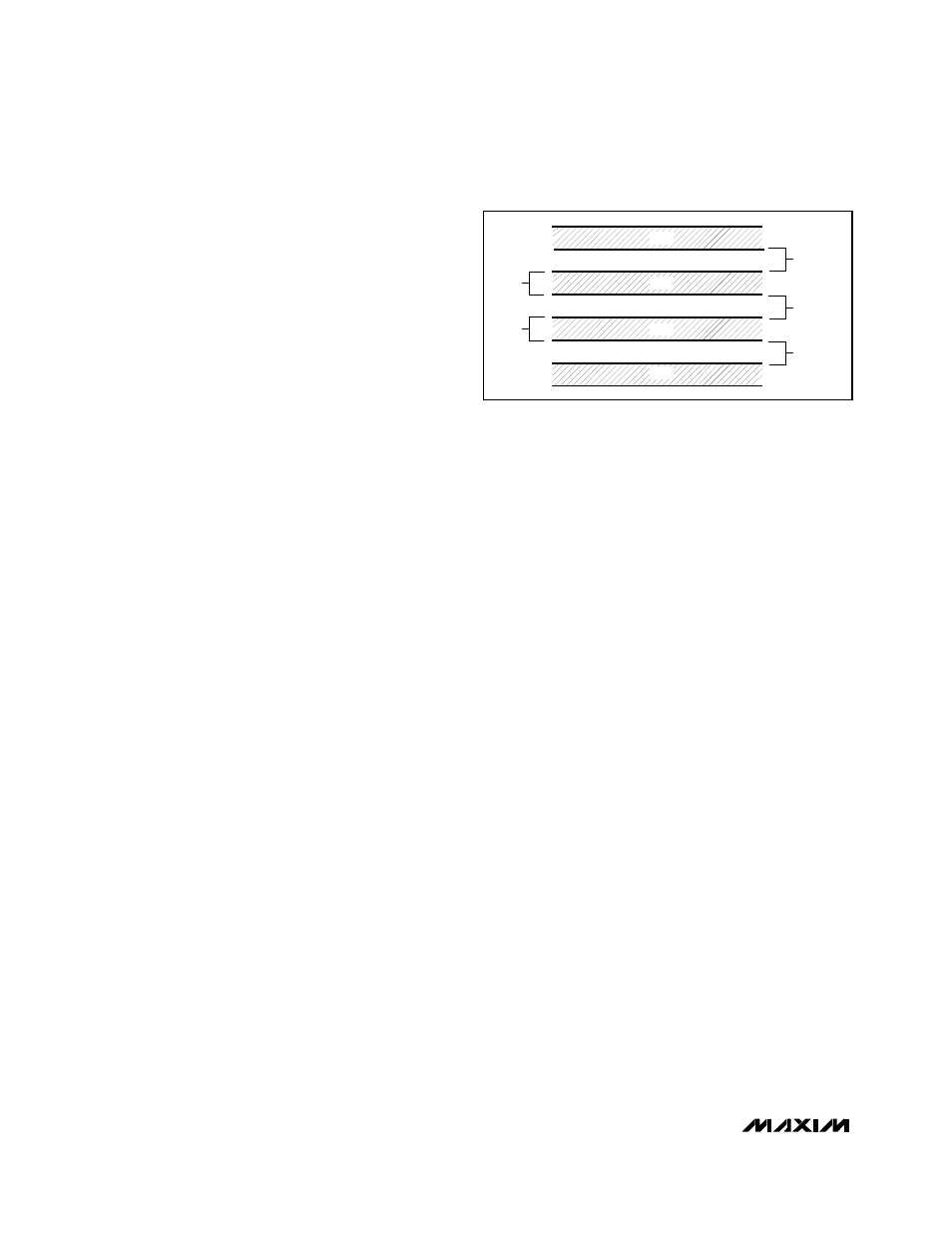

4) Connect guard traces to GND on either side of the

DXP-DXN traces (Figure 2). With guard traces in

place, routing near high-voltage traces is no longer

an issue.

5) Route through as few vias and crossunders as pos-

sible to minimize copper/solder thermocouple

effects.

6) When introducing a thermocouple, make sure that

both the DXP and the DXN paths have matching

thermocouples. In general, PC-board-induced ther-

mocouples are not a serious problem. A copper-

solder thermocouple exhibits 3µV/°C, and it takes

about 200µV of voltage error at DXP-DXN to cause

a +1°C measurement error. So, most parasitic ther-

mocouple errors are swamped out.

7) Use wide traces. Narrow traces are more inductive

and tend to pick up radiated noise. The 10mil

widths and spacings recommended in Figure 2

aren’t absolutely necessary (as they offer only a

MINIMUM

10mils

10mils

10mils

10mils

GND

DXN

DXP

GND

Figure 2. Recommended DXP/DXN PC Traces