Visualization of valve performance, Negligible long term maintenance costs – Dynatek Labs M6 User Manual

Page 5

Advanced Design Offers Significant Benefits in Heart Valve Testing

Innovative Test Chamber Design

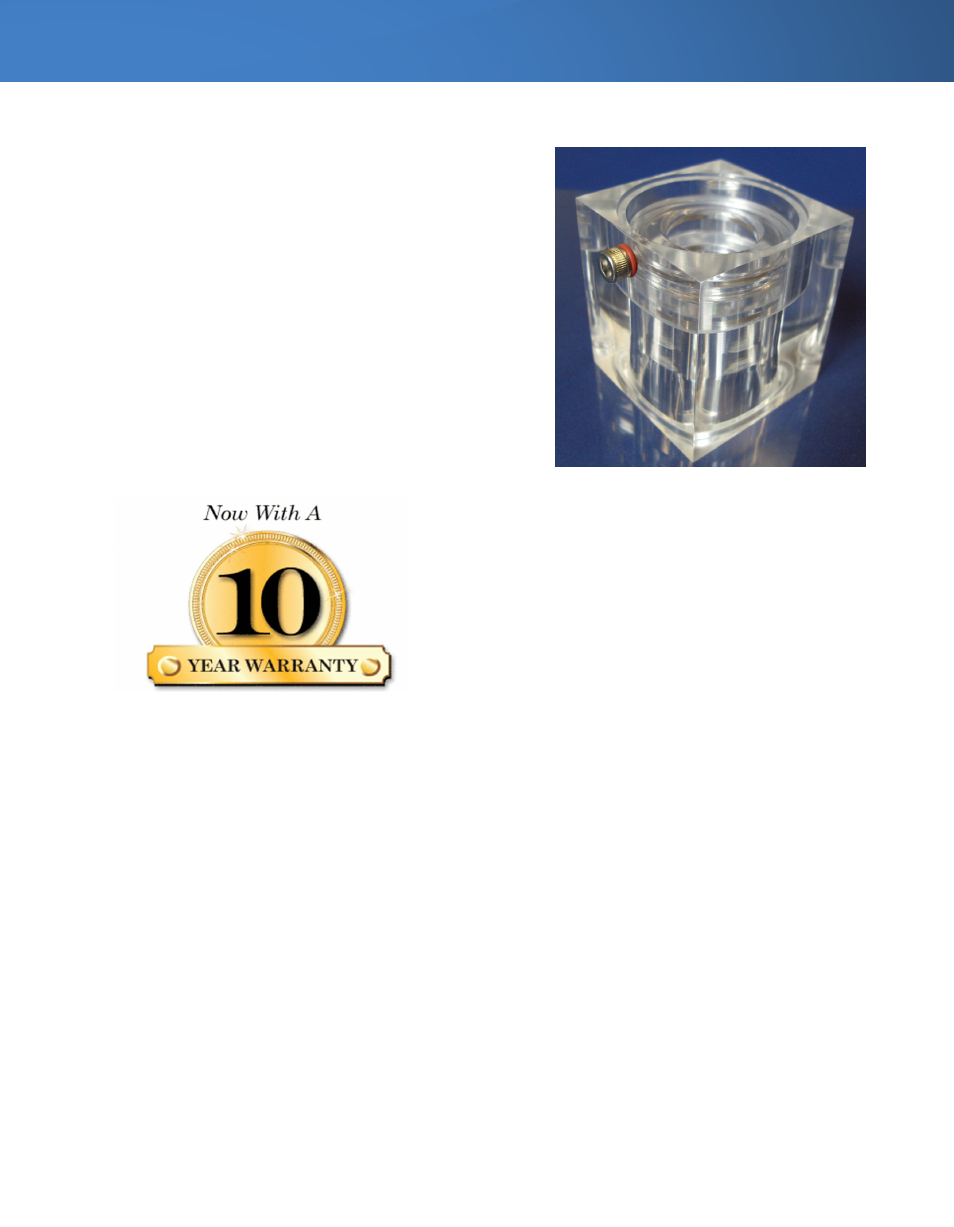

The M6’s test chambers are machined from a solid block of acrylic.

These test chambers are always custom-made, based on the user’s

heart valve design. Unlike competitive heart valve testers, the M6’s

test chambers do not move; instead, the test fluid moves through

the chamber, just like blood moves through the heart. Advantage:

since there is no reciprocating movement of the chambers, there is no

possibility of leakage of fluid around the test chambers due to leaking

sliding seals.

The M6’s test chambers are sequentially pressurized, which means that

the failure of a heart valve in one chamber does not lead to significant

pressure fluctuations in other test chambers or worse, the shutdown of

the whole unit. The M6 is the only heart valve tester in the world that

utilizes this principle, known as tuned fluid oscillation. This allows the

heart valves to be opened and closed fully while attaining targeted

closing pressures in the most biologically relevant way.

Visualization of Valve Performance

The M6 is an accelerated heart valve durability and fatigue

tester and one of its advantages is the ability for the user to

easily visualize and confirm the movement of the valve being

tested.

ISO 5840 requires visual observation of the test valve at

regular and frequent intervals such as daily or weekly. The

entire upper head, lower head and all test chambers are

made of clear, machined acrylic, allowing you to view both

the top and sides of the test valves conveniently.

All test chambers (and therefore the test valves) are stationary

in the M6, and you can conveniently use a video camera on

a tripod or a stroboscope to easily follow the motion of the

valve.

In competitive testers where the test chamber itself is moving

up and down at high speeds, it is very difficult to visually

follow the test valve’s performance with a stroboscope or a

high-speed camera, preventing the user from obtaining visual

data mandated by ISO.

Customized M6 test section

Negligible Long Term Maintenance Costs

Since the M6 does not use moving test chambers, it does not have

moving parts such as sliding seals, gears, and piston arms, and its

maintenance costs are negligible, compared to competitive units that

have many more parts that are moving. The M6 has a swash-plate that

compresses the bellows under each test chamber, loading every valve

in serial fashion, without the need for sliding seals and gears.

When you’re going to run a 400 million-cycle durability test, you want

to make sure that you have an absolutely reliable machine like the M6

that will not break down in the middle of a test. With the M6 you just

can’t go wrong, since it now comes with a 10-year limited warranty, the

longest such warranty in the industry!