Services – Rosen ROAIMS for Plants & Terminals User Manual

Page 6

SeRvIceS

Internationally accepted codes for above-ground storage

tanks such as EEMUA 159 and API 653 provide guidance

and recommendations for continuing tank operation.

ROSEN uses qualified Tank Integrity Assessors (TIA) to

perform inspections that comply with these standards.

Based on their findings, the TIA is able to carry out a full

compliance check and to give recommendations regard-

ing necessary yet cost-effective repairs. A full EEMUA

159/API 653 inspection includes, among other things,

the following services:

• Tank bottom inspection with ROSEN’s high-resolution

Tank Bottom Inspection Tool (TBIT)

• Shell inspection with ROSEN’s UT Crawler

• Detailed Visual Inspection of the tank structure,

including fittings and mountings

• Settlement survey and assessments

• Out-of-roundness surveys

• Engineering compliance checks

eeMUA 159/ApI 653 InSpecTIOn

RISk bASeD InSpecTIOn

ROSEN’s Risk Based Inspection (RBI) services & associ-

ated software is used to control a process for planning

inspection of above-ground storage tanks based on

environmental risk and complies with the principles of

API 580 in terms of RBI. The method improves tank avail-

ability at optimum cost and at the same time ensures

that integrity issues, including safety and environment,

are properly addressed. Priority is given to items in the

higher risk categories that need to be monitored closely.

Utilization of RBI provides a vehicle for continuously

improving the inspection of tanks and facilities in general

and for systematically reducing the risk associated with

credible failure. The ultimate deliverable is of course a

cost-effective inspection and/or monitoring plan which

serves as input for the overall maintenance management

system.

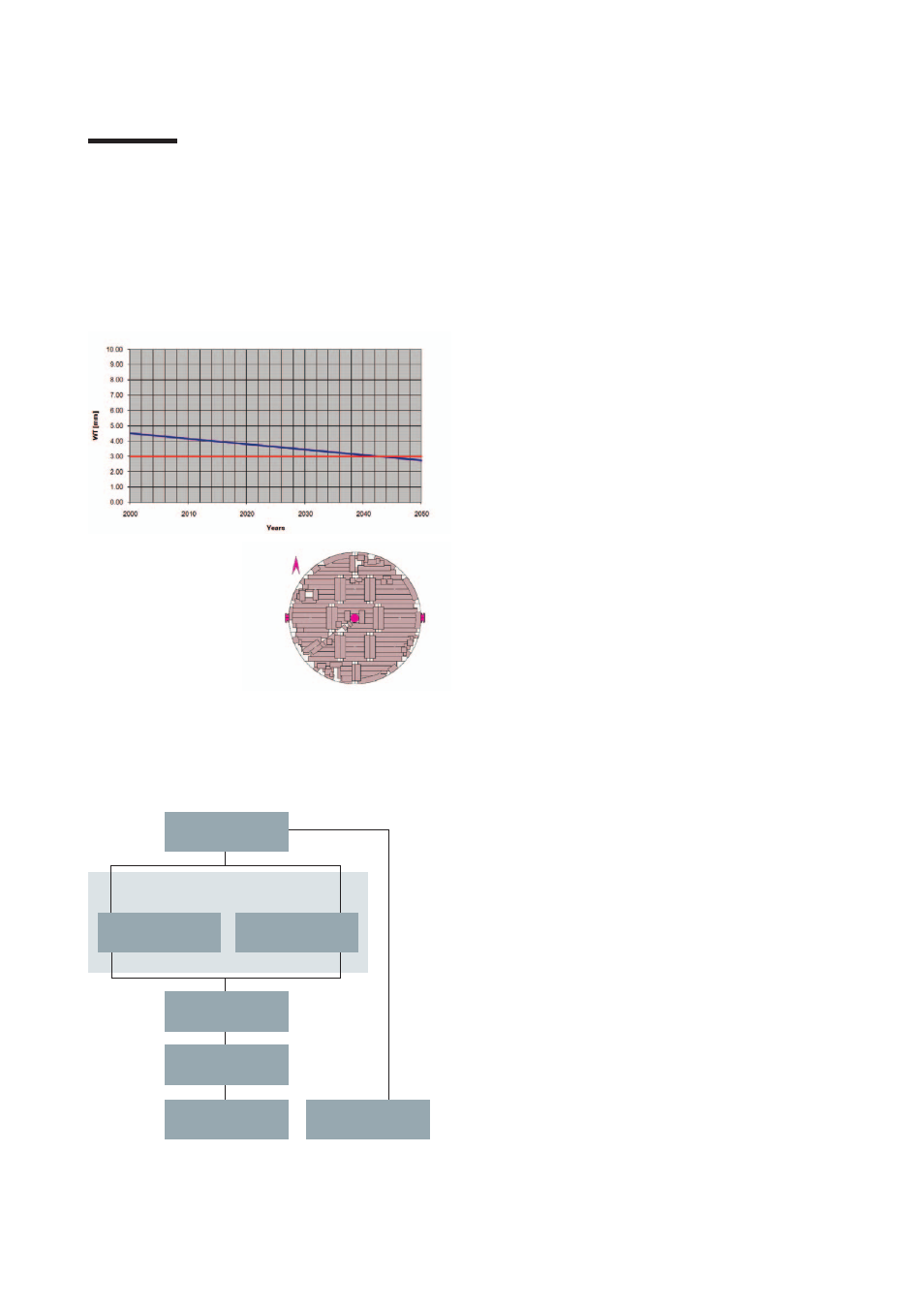

Remaining life assessment:

estimated degradation of the sketch plates

Data and Information

collection

consequence

of Failure

propability

of Failure

Risk Assessment process

Risk Ranking

Inspection plan

Mitigation (if any)

Reassessment