Grain Systems Bin Flooring PNEG-218 User Manual

Page 9

2. Recommended Method for Full Floor Installation

PNEG-218 30' Cor-Lok and Cut-Lok Flooring

9

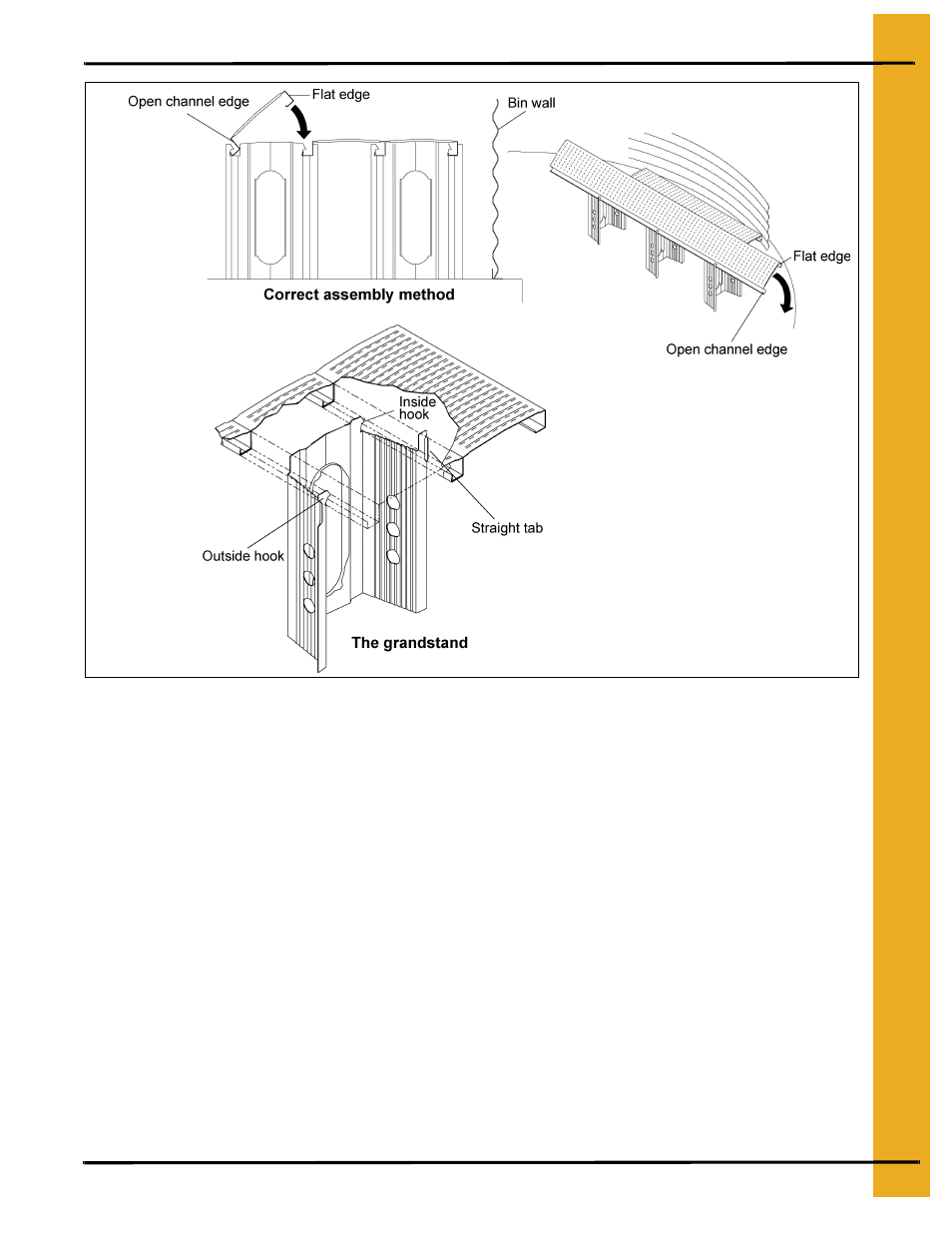

Figure 2C

4. Install flooring starting at the bin wall on the opposite side of the unload auger. Floor planks should

be placed perpendicular to the unload auger with the outside edge the correct distance from the

center of the bin.

Be sure the flat edge of the floor plank is facing the

bin wall and the open channel edge is facing towards the center of the bin.

Position

the supports for the first/shortest floor plank according to the number of bin rings and corrugation as

shown in the illustrations

or stated in the charts

. Attach the flashing

to flooring and bin wall to hold plank in place. (

for flashing installation.)

5. POSITION THE NEXT ROW OF SUPPORTS ACCORDING TO THE CHALK LINES and support

layout. The straight tab should “snap” under the first (previous) floor piece. After the supports in

the row are correctly positioned, install the next floor piece by hooking the open channel edge

under the outside hooks of the floor supports. Push down sharply on the edge of the floor piece

until it snaps into the previous floor piece.

Continue this process for the rest of the

floor cutting planks for center and intermediate wells as needed.

for

center well support locations.

NOTE: Whenever there is more than Dimension B divided by three inches (B/3") of plank unsupported

beside the bin wall, there should be a support on that plank or a support on each of the planks

adjacent to it such that no more than Dimension B divided by three inches (B/3") is unsupported.

For example: 2.66" bin with 8 rings has a “B” dimension of 22". Take 22"/3" = 7.33" (Round to

7"). Therefore, there should be no more than 7" of unsupported floor plank.

IMPORTANT: First piece of flooring must start at the

proper distance from centerline of bin. Refer to floor

layout

trimmed for length to fit at the proper location.