Bolting and hardware requirements, Chapter 7 bolting and hardware requirements, Hardware – Grain Systems Tanks PNEG-972 User Manual

Page 19: Identifying bolt grades

PNEG-972 Construction Manual for 2.66" Corrugation 105' Diameter Tall Tanks (28 Rings and Taller)

19

7. Bolting and Hardware Requirements

Hardware

Identifying Bolt Grades

IMPORTANT: Bolts should not be tightened in excess of the torque specifications listed

.

Hardware usage is detailed in the bolting requirement charts

, stiffener and splice

hardware charts

and the bolting and the hardware requirements section

.

Torque (ft. lbs.)

Bolt Size

Minimum

Maximum

5/16"-18

15

20

3/8"-16

35

42

7/16"-14

65

72

1/2"-13

95

105

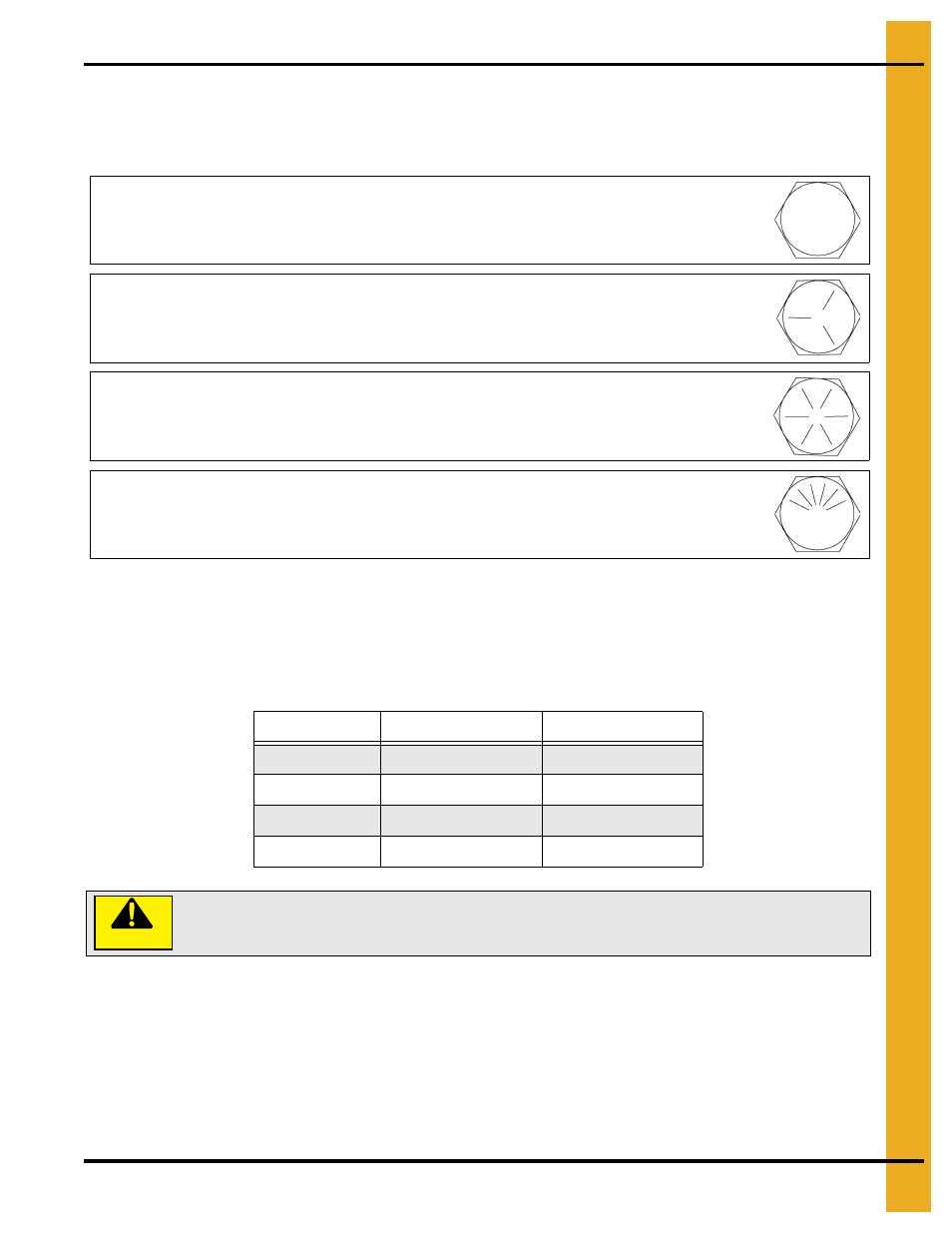

Grade 2 Bolts

1. Grade 2 bolts are designated with a plain head and are not used in

GSI grain bins/silos.

Grade 5 Bolts

2. Grade 5 bolts are designated by three (3) slash marks on the head.

All 5/16" diameter bolts are to be grade 5 or higher.

Grade 8 Bolts

3. Grade 8 bolts are designated by six (6) slash marks evenly spaced out

around the head of the bolt.

Grade 2 Bolts

4. Grade 8.2 bolts are designated by six (6) slash marks on the head in a sunrise

pattern. All 3/8" and 7/16" diameter bolts are to be grade 8 or 8.2.

Under no condition shall any other bolts be substituted for those supplied by

the manufacturer.

CAUTION