Banks Power Ford Motorhomes: (Gas ’97 - 05 6.8L V-10, Class-A (20-valve)) Power Systems- PowerPack, Stinger & Git-Kit Systems, (Class-A) '97-05 User Manual

Page 8

tube to allow the tube to be positioned

properly.

16.

Make sure the O-ring is on the

dipstick tube, and reinstall it into the

hole in the engine block. Reattach the

dipstick tube bracket to the cylinder

head with the new, longer bolt and

spacer supplied. Reattach the bracket

at the radiator core support with the

original hardware and put the dipstick

back in.

17.

If additional clearance at the front

of the right side TorqueTube manifold

for the air conditioning hose is needed,

very gently bend the line away from

the manifold until there is a minimum

of

3

⁄

4

” of clearance. Do not use a pry

bar or other tool to bend it as this

may damage the line. Wrap the air

conditioning line with the aluminum

heat shielding blanket provided, and

tie it with the supplied wire ties.

18.

If it was removed, reinstall the

crossmember at the front of the

vehicle.

19.

Place the new catalytic converter

flange gasket onto the studs on the

catalytic converter flange. Install the

Y-pipe onto the catalytic converter

using the original hardware, and the

pin hanger into the rubber hanger

on the frame of the vehicle. Place

a conical seal into the flare at the

forward end of the Y-pipe, and

attach the Y-pipe to the right side

TorqueTube manifold using the

3

⁄

8

” x

1

3

⁄

4

” bolts and washers provided. Do

not tighten the bolts yet.

20.

Slip a 2

1

⁄

2

” muffler clamp over

the free end of the Y-pipe, and then

slide the Y-pipe extension into the slip

joint. With the slip joint fully seated,

mark the extension pipe with a pen

so that as the clamp is tightened, any

slippage of the joint can be observed.

Place the second conical seal onto

the flare on the extension, and attach

the extension pipe to the left side

TorqueTube with the

3

⁄

8

” x 1

3

⁄

4

” bolts

and washers provided. Tighten the

2

1

⁄

2

” clamp at the slip joint, observing

the mark to be sure the joint stays

fully seated as the clamp is tightened.

Up to

1

⁄

4

” slip is acceptable. Tighten

the bolts at the manifold collectors.

21.

Install and tighten the oxygen

sensors into the threaded bungs

provided on the Y-pipe and extension.

Use a small amount of anti seize on

the threads of the oxygen sensors. Be

careful to not get any anti-seize on the

sensor elements themselves.

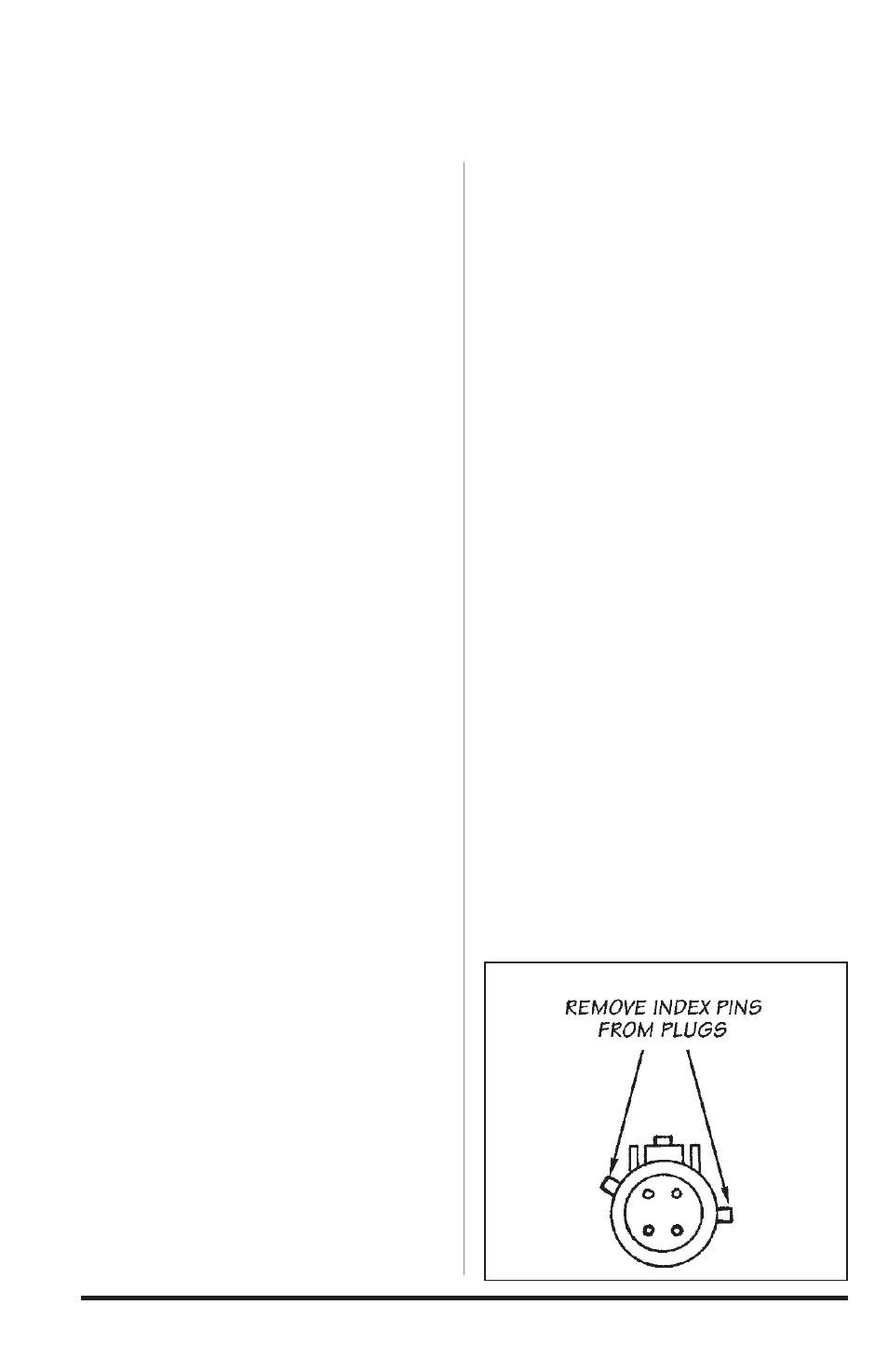

22.

On the connector on the oxygen

sensor and on the male connector on

the sensor extension lead, remove the

two index pins on the connector shell,

by cutting or filing. Be careful to not

damage the locking mechanism of the

connectors. see

figure 4.

23.

Plug the oxygen sensor extension

leads included in the kit into the

wiring harness where each sensor

was previously connected, then plug

the sensor lead into the extension.

Secure the leads away from any pipes

or moving linkages with the cable ties

provided.

-end, section 1-

Figure 4

8

96378 v.6.0