Banks Power Ford Motorhomes: (Gas ’97 - 04 6.8L Class-C) Power Systems- PowerPack & Stinger Systems & Optional OttoMind (Class-C) User Manual

Page 8

11.

Locate a wire connector block

mounted on a bracket on the left side

frame rail. This connector must be

relocated to allow clearance for the

left side TorqueTube. Unbolt the wire

connector from the bracket and roll it

around to mount on top of the frame

rail. Secure the connector to the frame

rail using the tie wraps provided. Wrap

the wires and connector with the heat

shield blanket provided and secure

with the wire ties.

12.

Disconnect the positive cable

from the starter. Remove the starter

from the vehicle.

13.

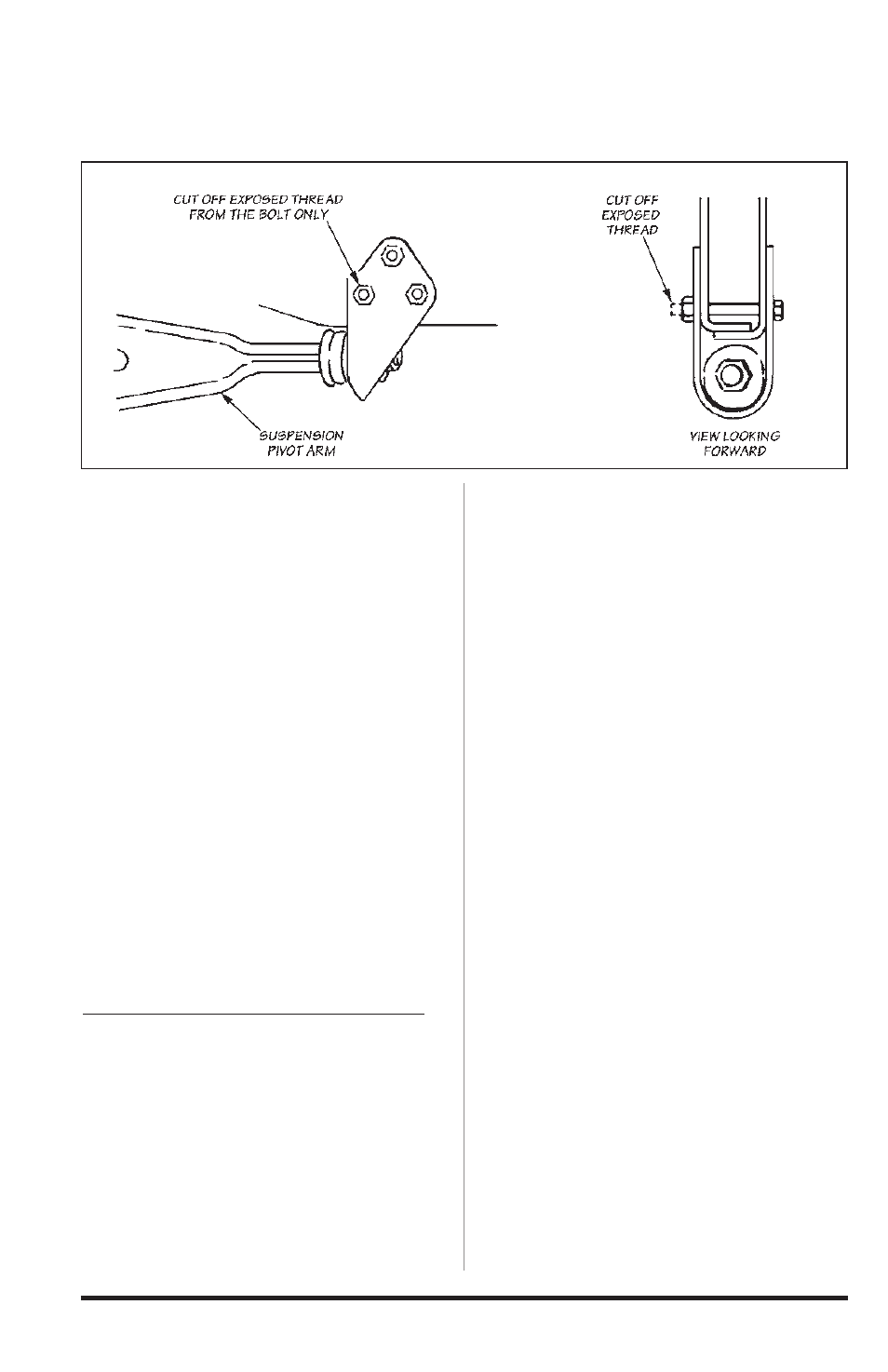

On the passenger side of the

vehicle, cut off all excess thread

protruding thru the nut on the forward

bolt attaching the suspension pivot

arm to the frame as shown in

Figure 3.

Banks Torque Tube Installation

14.

Inspect the exhaust mounting

surfaces of the cylinder heads

and clean away any deposits to

assure proper sealing of the Banks

TorqueTubes. Be careful when doing

this as the cylinder heads are made

from aluminum, and can be easily

damaged. We recommend the use of a

Scotchbrite

®

pad.

15.

Place a small amount of anti-seize

on the threads of each of the supplied

manifold bolts. Use the new gaskets

provided when installing TorqueTubes.

Lift the Banks TorqueTube manifolds

into place and install one or two bolts

to hold them in position.

16.

Attach the EGR tube to

the adapter fitting in the Banks

TorqueTube manifold. If necessary,

loosen the fitting at the top of the EGR

tube to allow the tube to be positioned

properly.

17.

Install the remaining bolts into the

heads and tighten.

18.

Reinstall the starter motor using

the factory fasteners. Route the starter

cable away from the manifold.

19.

Inspect the exhaust manifold

installation for any wiring, hoses, or

carpet padding/insulation that are

within 2-3 inches of the manifolds or

EGR tubes. Tie wires away from the

exhaust components as required.

Trim away any carpet padding within

2 inches of the EGR tubes or exhaust

components. On some models the oil

cooler hoses may contact the header

heatshield. Reposition the cooler

hoses away from the heatshield using

wire ties or by twisting the ends of the

hoses at the connection to the oil filter

base. See Figure 4.

Figure 3

8

96401 v.9.0