Installation instructions, Figure 1 – Banks Power Ford Motorhomes: (Gas ’93 - 98 7.5L Class-A) PowerPack system (Class-A, Carb, JD-OK Chassis) For use w_ 460 carbureted engine User Manual

Page 5

installation instructions

remove the “dog house” cover from the

engine for acess.

If a heavy duty hoist is available, raise the

vehicle and remove the front wheels for

easier access. If the rear wheels remain on the

ground, block the rear whels.

disconnect all cables from the batterys).

starting from the rear of the vehicle and

working forward, remove the exhaust

system from the vehicle. leave exhaust pipe

hangers in place on the chasis.

disconnect the rubber hoses from the air

injection tubing on the exhaust manifolds.

remove the exhaust manifolds from the engine.

(see notes on bolt removal)

note: Some models do not use manifold air injec-

tion. If not equipped with manifold air injection,

go to step 7.

remove the air injection tube assemblies

from the exhaust manifolds. you may need

to use heat and/or penetrating oil on the tubing

nuts. use a flare-nut wrench to avoid rounding of

the corners of the tubing nuts.

disconnect the main positive power cable

(large red cable) from the stud on the starter

motor.

re-route the main power cable to the

starter motor by feeding the cable between

the side engine mount and the oil pan. cut the

plastic cable ties on the forward part of the cable

bundle as required to provide slack as needed for

the new cable routing. re-connect the cable to

the starter motor.

inspect the cylinder head exhaust flange

surfaces. remove any loose carbon, rust,

old gasket material, etc. as required to provide a

clean, flat manifold mounting surface.

put the transmission in low gear (make sure

wheels are blocked to prevent rolling). bolt

the banks exhaust manifolds to the cylinder heads.

use the new gasket/heat shields provided between

the cylinder heads and manifolds. attach the new

manifolds with

3

⁄

8

–16 x 1 inch 12-point bolts. use

anti-sieze compound on the threads.

re-install the air injection tubing assemblies

to the new exhaust manifolds. hook up

the hoses to the air injection tubing assemblies.

(if engine is not equipped with a manifold air

injection system, install eight plugs, provided, in

the new exhaust manifods.)

re-connect the hot air tube from the air

cleaner to the heat stove pipe on the

exhaust maniold.

check that the re-routed cable to the starter

motor has at least 3 inches of clearance to

any part of the exhaust manifold tubing. also

check that the cable will not rub on any sharp

edges that could cut through the insulation and

cause a short. reposition or tie the cable in place

to correct any of these conditons.

starting from the exhaust manifold

outlets, install the new exhaust piping and

muffler (see Figure

1

). the two floating exhaust

flanges must be slid onto the head pipes prior to

installation. note the new position of the spring at

the forward muffler hanger. universal hangers and

clamps are provided for your use if necesary.

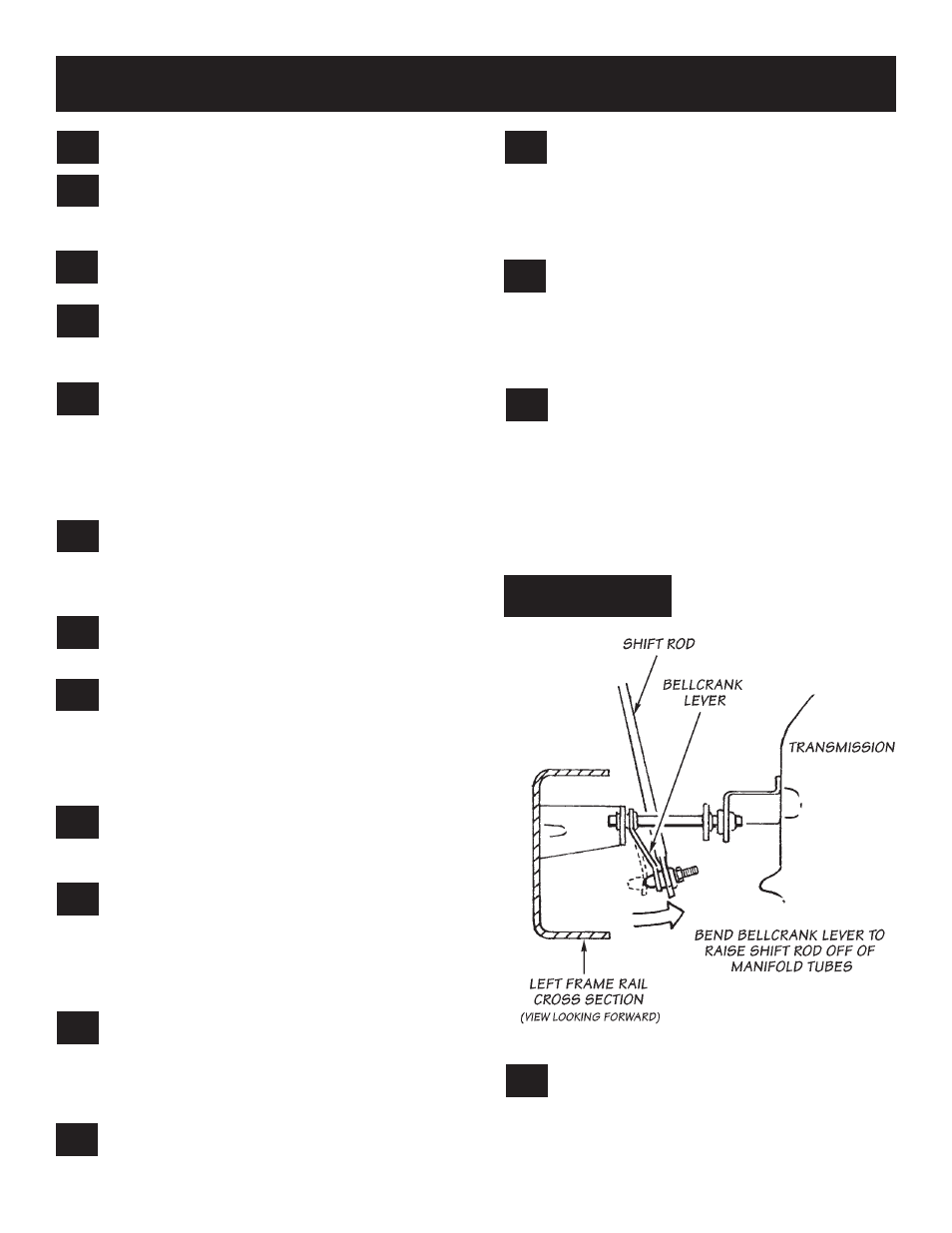

To prevent the transmission shift rod from

rattling against the exhaust manifold tubes,

bend the shift rod bellcrank lever as required to

provide clearance between the tubes and the

rod. run the shift lever in the vehicle through all

gear positions, and check that the shift rod clears

the exhaust tubes. If possible, try to maintain

1

⁄

4

inch or more clearance to prevent contact during

engine rock-over. See Figue

2

.

bolt the heat shield bracket to the left side

heat shield using two

5

⁄

16

–18 x

3

⁄

4

hex bolts,

5

⁄

16

I.d. x

9

⁄

16

o.d. washers, and

5

⁄

16

–18 nylock nuts

(see Figure

3

).

16.

15.

14.

13.

12.

11.

10.

9.

8.

7.

6.

5.

4.

3.

2.

1.

5

p.n. 96345

fIgure 1