Milton CAT 501HD User Manual

Page 2

Cat

®

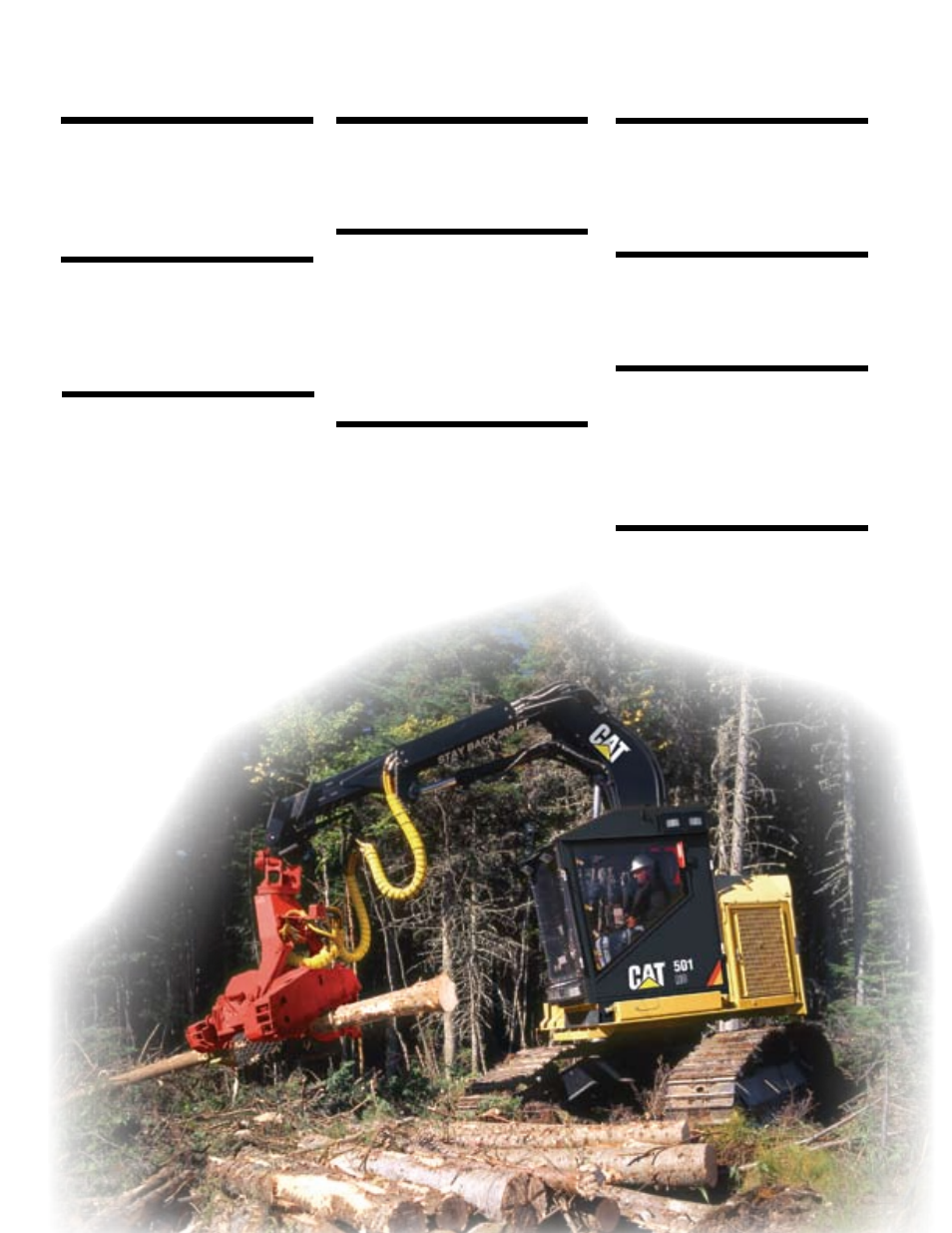

501 and 501HD Track Harvesters

The tilt cab feature allows excellent access for service or daily maintenance needs.

Power Train

The Cat C6.6 ACERT Tier III Engine

provides excellent power, fuel economy,

serviceability, and durability while

meeting Tier III emissions standards.

Operator Station

The unique front entry cab allows for

easy entry and exit. Debris does not

collect on the reverse slope windshield.

Serviceability

The tilt cab feature allows excellent

access for service or daily maintenance

needs.

Unobstructed Visibility

The engineered cab forward and

rear engine design gives exceptional

operator visibility. Better visibility

means more production.

Counterweight

A large capacity fuel tank and hydraulic

oil tank are integrated into the

counterweight design.

Electronic Control System

The IQAN

®

computer based control

system provides precise control of

machine and attachment functions

through the fully proportional valving

system. All gauges are monitored on a

single MDL full color screen.

Engineered Productivity

The large heavy-duty swing bearing

and high swing torque enhance

productivity.

Equipped with dependable Cat

engines, load sensing hydraulics,

and factory installed attachments,

Caterpillar track harvesters offer

the perfect solution for any

cut-to-length application.

Undercarriage

The proven x-design carbody and

large track system provide strength

and durability. Side rails are designed

so that debris does not collect. The

fully-guarded, forestry-duty high walker

undercarriage has integrated welded

track guards.

Boom Options

Optional 8.2 m (27’) Telescoping “V”

Bottom (5-sided) Harvester Boom.

Standard Booms Range from 6.4-7.0 m

(21’-23’).

Attachments

A full line of Prentice processor/

harvester heads are available, factory

installed. Consult a Prentice Processing

Head specification sheet for specific

models and carrier application guide.

2