4 mounting, 1 general instructions – VEGA VEGABAR 55 4 … 20 mA_HART - climate compensated User Manual

Page 12

12

4 Mounting

VEGABAR 55 • 4 … 20 mA/HART - climate compensated

39441-EN-130321

4 Mounting

4.1 General instructions

Make sure that all parts of the instrument coming in direct contact

with the process, especially the sensor element, process seal and

process fitting, are suitable for the existing process conditions, such

as process pressure, process temperature as well as the chemical

properties of the medium.

You can find the specifications in chapter "Technical data" and on the

nameplate.

To protect the diaphragm, the process fitting is covered by a protec-

tive cap.

Remove the protective cap just before installation so that the dia-

phragm will not get damaged. It is recommended to keep the cap and

use it again later for storage or transport.

Select an installation position you can easily reach for mounting and

connecting as well as later retrofitting of a display and adjustment

module. The housing can be rotated by 330° without the use of any

tools. You can also install the display and adjustment module in four

different positions (each displaced by 90°).

Use the recommended cables (see chapter "Connecting to power

supply") and tighten the cable gland.

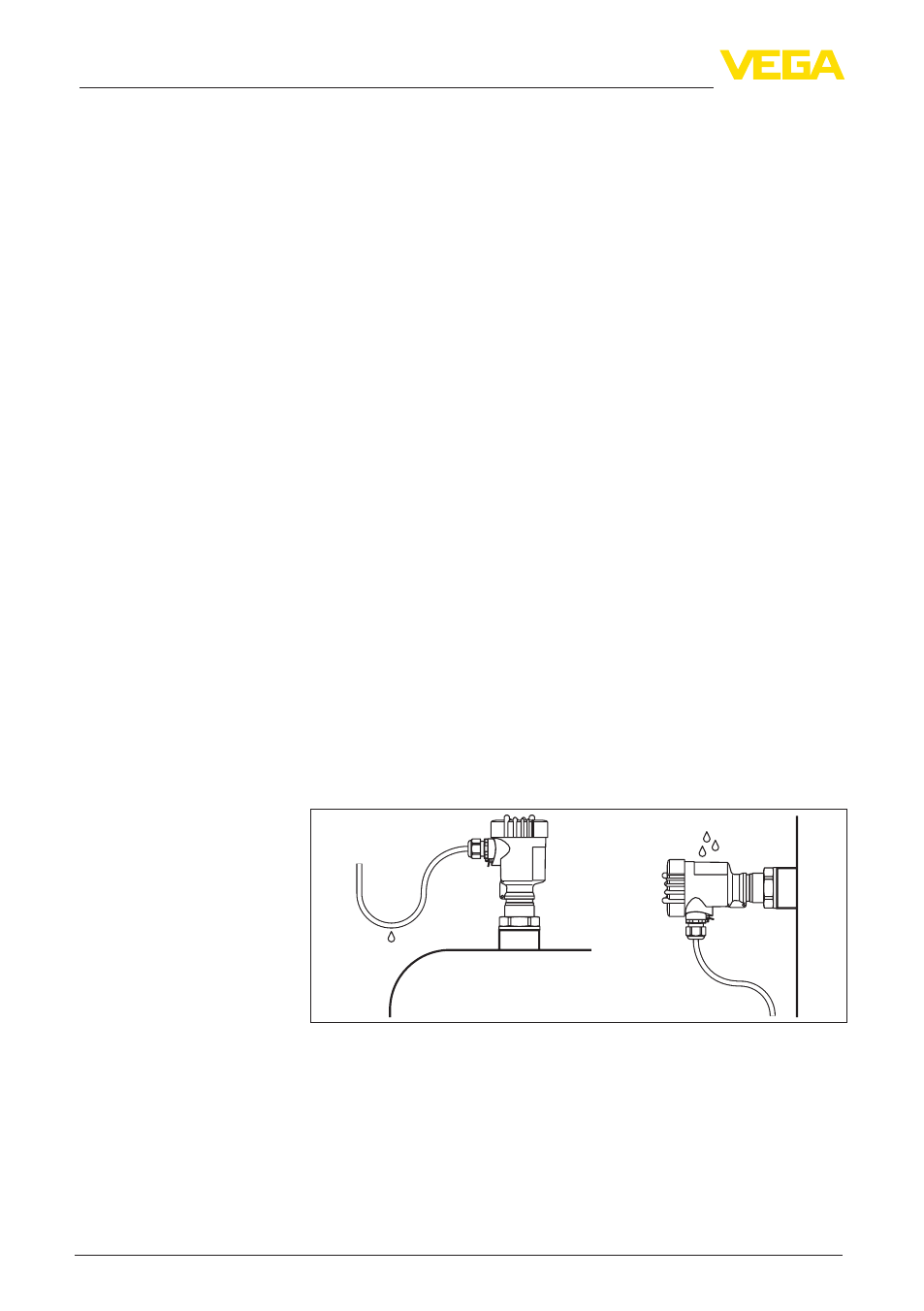

You can give your instrument additional protection against moisture

penetration by leading the connection cable downward in front of the

cable entry. Rain and condensation water can thus drain off. This ap-

plies mainly to outdoor mounting as well as installation in areas where

high humidity is expected (e.g. through cleaning processes) or on

cooled or heated vessels.

Fig. 3: Measures against moisture penetration

The ventilation of the electronics housing as well as the atmospheric

pressure compensation for the measuring cell are realised via a filter

element in the area of the cable gland.

Suitability for the process

conditions

Diaphragm protection

Installation position

Moisture

Ventilation and pressure

compensation