VEGA VEGABAR 67 Profibus PA - climate compensated User Manual

Page 56

56

10 Supplement

VEGABAR 67 • Profibus PA - climate compensated

39445-EN-130321

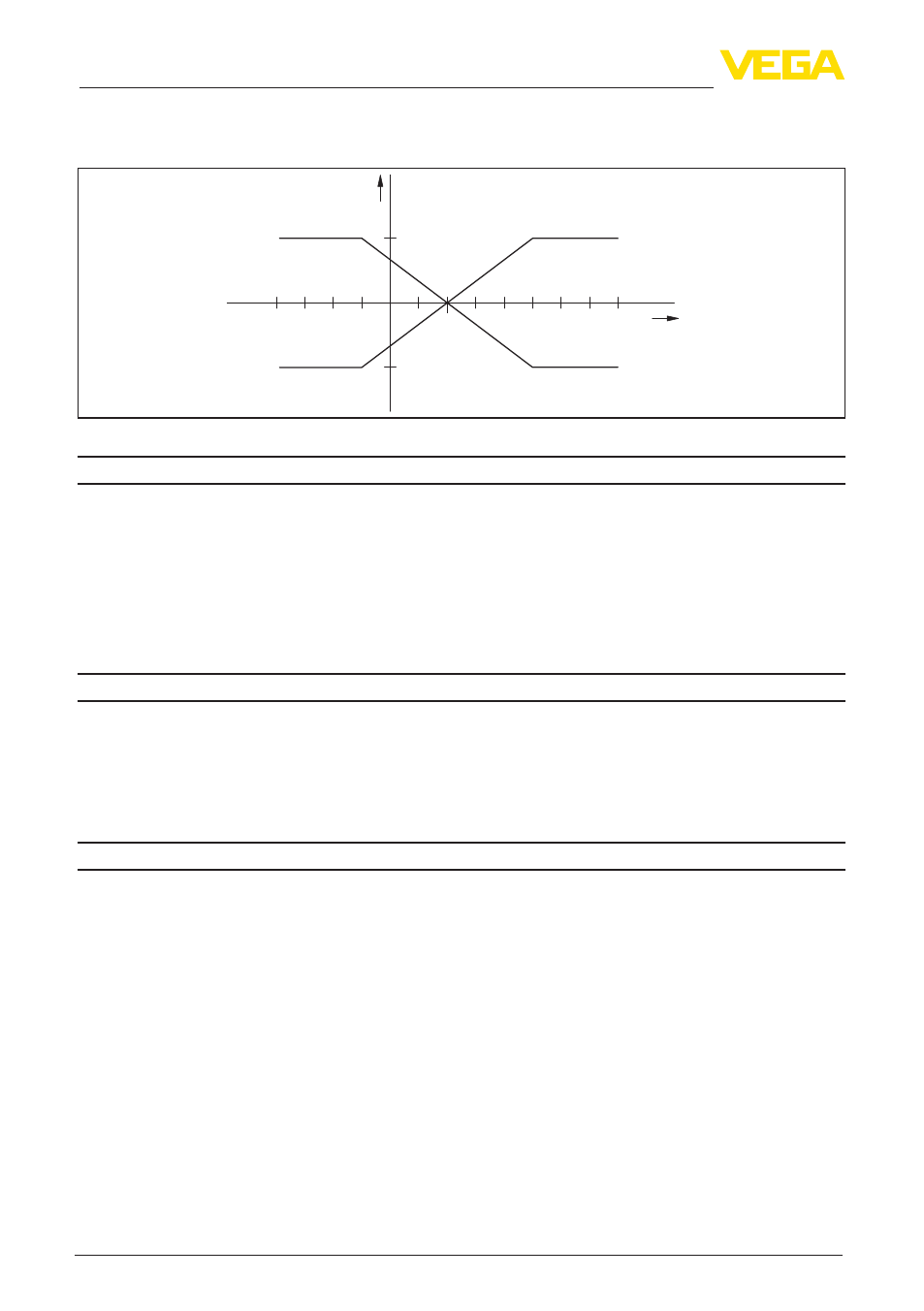

Thermal change, current output

< 0.05 %/10 K, max. < 0.15 %, each with -40 … +80 °C

(-40 … +176 °F)

0,15 %

-0,15 %

-40°C

-20°C

20°C

40°C

60°C

80°C

Fig. 32: Thermal change, current output

Long-term stability (according to DIN 16086 and IEC 60770-1)

Applies to digital HART interface as well as to analogue current output 4 … 20 mA under refer-

ence conditions. Specifications refer to the set span. Turn down (TD) is the relation nominal meas-

uring range/set span.

Long-term drift of the zero signal:

Ʋ For one year

< 0.05 % x TD

Ʋ For five years

< 0.1 % x TD

Ʋ For ten years

< 0.2 % x TD

Ambient conditions

Ambient, storage and transport temperature

Ʋ Version with connection tube

-40 … +80 °C (-40 … +176 °F)

Ʋ Version with suspension cable FEP,

PUR

-20 … +80 °C (-4 … +176 °F)

Ʋ Version with suspension cable PE

-20 … +60 °C (-4 … +140 °F)

Process conditions

The specifications of the pressure stage and product temperature are used as an overview. The

specifications on the type label are applicable.

Process pressure

Ʋ with measuring ranges 0.1 bar

(1.45 psig) or 0.2 bar (2.9 psig)

max. 15 bar (217.6 psig) or max. 20 bar (290 psig)

12)

Ʋ with meas. ranges from 0.4 bar

(5.8 psig)

max. 25 bar (363 psig)

13)

Pressure stage, process fitting

Ʋ Threaded fitting

316L PN 3, PVDF PN 5

14)

Ʋ Thread

316L PN 25, PVDF unpressurized

Ʋ Lock fitting

Unpressurized

12)

Limited by the overpressure resistance of the measuring cell.

13)

Limitation by the pressure-tightness of the cable connection.

14)

Limited by the overpressure resistance of the measuring cell.