VEGA VEGAFLEX 62 Profibus PA User Manual

Page 40

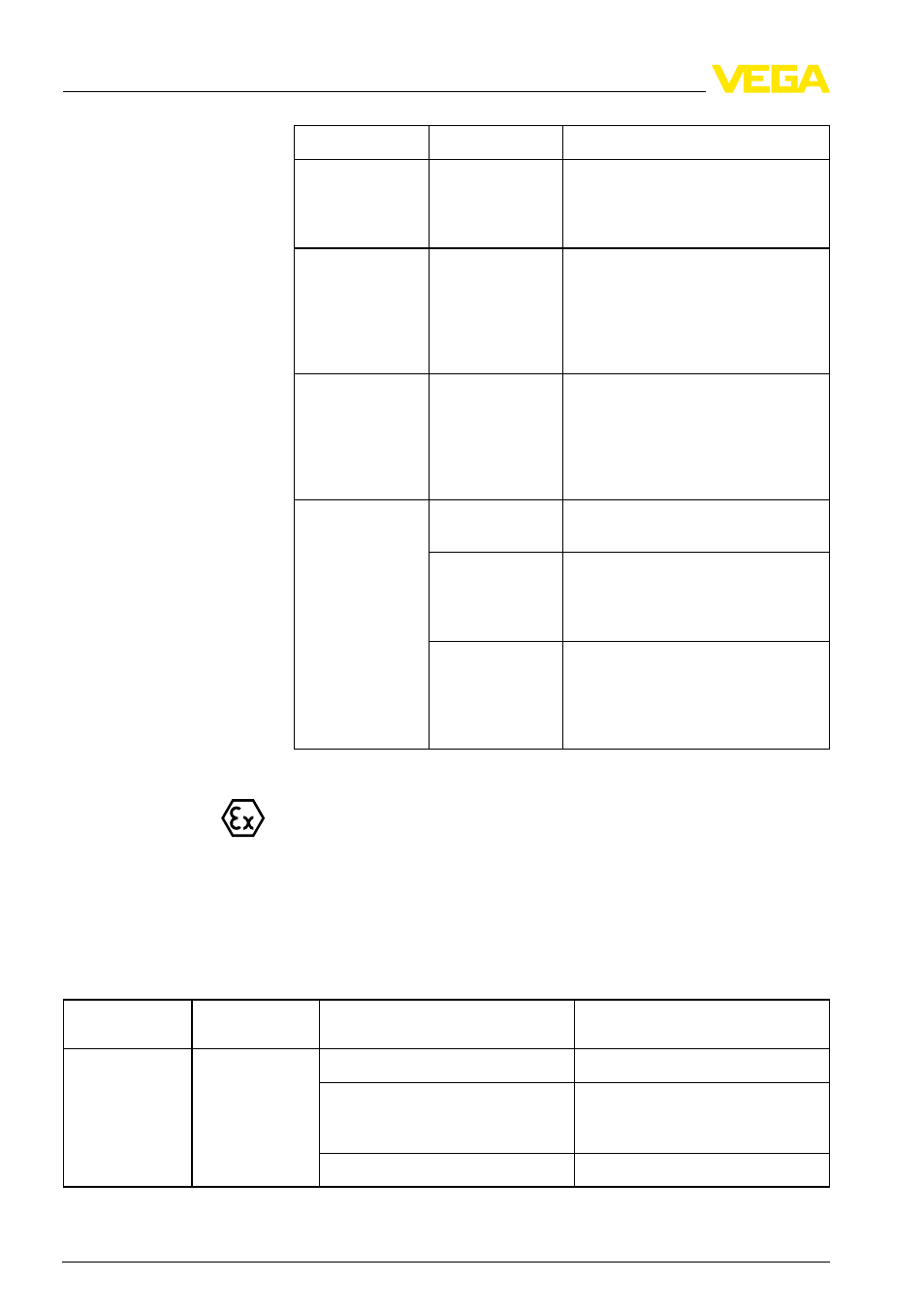

Error

Cause

Removal

In Simatic S7 the

measured value is

always presented

as 0

Only four bytes

are consistently

loaded in the PLC

Use function component SFC 14 to

load 5 bytes consistently

Measured value

on the indicating

and adjustment

module does not

correspond to the

value in the PLC

The menu item

"

Display - Dis-

play value

"

is

not set to "

PA-

Out

"

Check values and correct, if neces-

sary

No connection

between PLC and

PA network

Incorrect adjust-

ment of the bus

parameter and

the segment

coupler-depen-

dent baud rate

Check data and correct, if necessary

Instrument does

not appear during

connection setup

Profibus DP cab-

le pole-reversed

Check cable and correct, if necessary

Incorrect termina-

tion

Check termination at the beginning

and end points of the bus and termin-

ate, if necessary, according to the

specification

Instrument not

connected to the

segment, double

assignment of an

address

Check and correct, if necessary

In Ex applications, the regulations for the wiring of intrinsically safe

circuits must be observed.

The indicating and adjustment modules indicates faults via error codes

and text messages. The following table describes the error codes with

status according to NE 107 and gives information on the causes of

failure and their removal:

Status accor-

ding to NE 107

Error code

Text message

Cause/Rectification

Failure

E

013

no measured value available

Sensor in boot phase

no measured value available

Sensor does not find an echo, e.g.

due to faulty installation or wrong

parameter adjustment

no measured value available

Wrong sensor length entered

Error messages via the

indicating and adjust-

ment module

40

VEGAFLEX

62 • Profibus PA

8 Maintenance and fault rectification

31839

-EN

-100426