2 mounting instructions – VEGA VEGAPULS 66 (≥ 2.0.0 - ≤ 3.8) enamel Profibus PA User Manual

Page 14

1

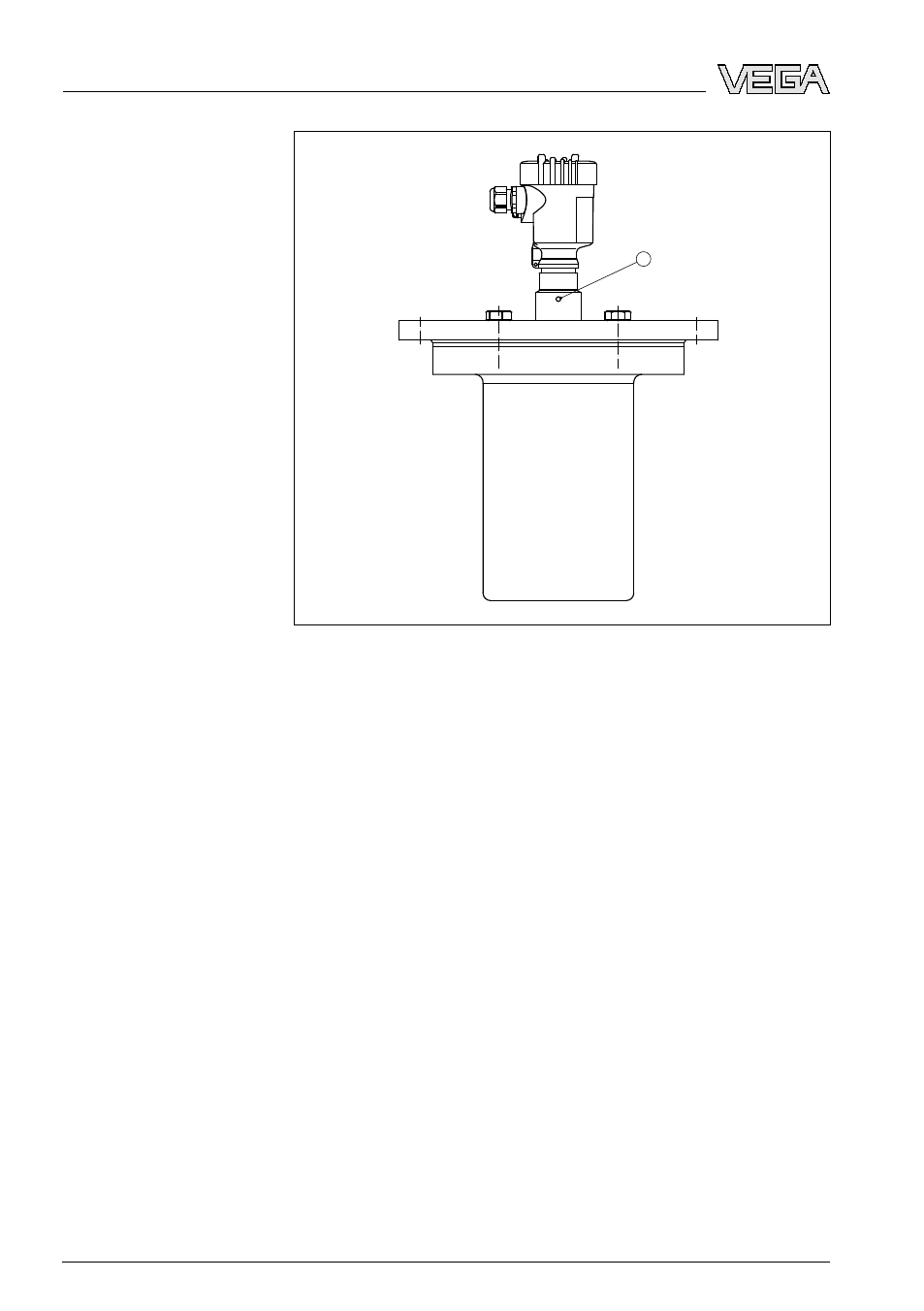

Fig. 4: Position of the polarisation plane with VEGAPULS 66

1

Marking hole

Make sure that all parts of the instrument in contact with the measured

product, especially the sensor element, process seal and process

fitting, are suitable for the existing process conditions such as process

pressure, process temperature as well as the chemical properties of

the medium.

You can find the specifications in chapter "Technical data" in the or on

the type label.

Instruments with enamel coating should be treated very carefully and

shocks should be avoided. Unpack VEGAPULS 66 directly before

installation. Insert VEGAPULS 66 carefully into the vessel opening and

avoid touching any sharp vessel parts.

4.2 Mounting instructions

When mounting VEGAPULS 66, keep a distance of at least 500 mm

(19.69 in) to the vessel wall. If the sensor is installed in the center of

dished or round vessel tops, multiple echoes can arise. These can,

however, be suppressed by an appropriate adjustment (see chapter

"

Setup").

Suitability for process

conditions

Enamel coating

Mounting position

14

VEGAPULS

66 enamel • Profibus PA

4 Mounting

33335

-EN

-090305