2 mounting instructions – VEGA VEGACAP 64 - contactless electronic switch User Manual

Page 12

12

4 Mounting

VEGACAP 64 • - contactless electronic switch

30013-EN-130916

The process fitting must be sealed if there is gauge or low pressure in

the vessel. Before use, check if the seal material is resistant against

the measured product and the process temperature.

The max. permissible pressure is specified in chapter "Technical

data" or on the type label of the sensor.

4.2 Mounting instructions

Due to the effects of agitators, equipment vibration or similar, the level

switch can be subjected to strong lateral forces. For this reason, do

not use an overly long electrode for VEGACAP 64, but check if you

can mount a short level switch on the side of the vessel in horizontal

position.

Extreme vibration caused by the system, e.g. due to agitators or

turbulence in the vessel from fluidisation, can cause the probe of

VEGACAP 64 to vibrate in resonance. If a longer rod version is neces-

sary, you can secure the probe by fastening a suitable brace or guy

directly above the end of the rod.

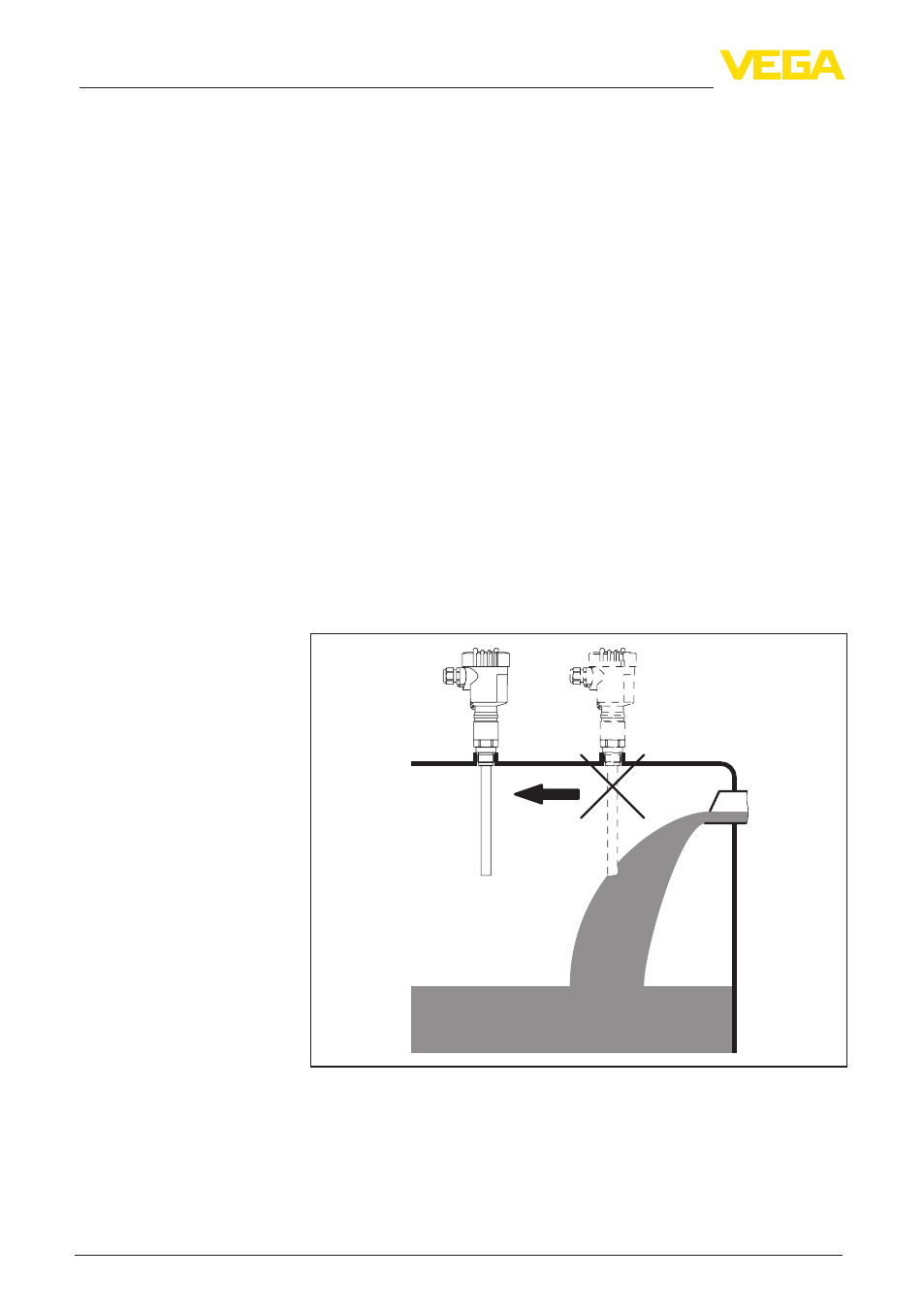

If the instrument is mounted in the filling stream, unwanted false

measurement signals can be generated. For this reason, mount the

instrument at a position in the vessel where no disturbances, e.g. from

filling openings, agitators, etc., can occur.

This applies particularly to instrument versions with a longer probe.

Fig. 5: Inflowing medium

To compensate the normal voltage loss due to sealing materials, you

have to additionally use disc springs for fastening flange screws on

PTFE coated flanges. Tighten the screws moderately with the torque

stated in the technical data.

Pressure/Vacuum

Agitators and fluidization

Inflowing medium

Torque with PTFE plated

flanges