7 maintenance and fault rectification, 1 maintenance, 2 remove interferences – VEGA VEGASWING 51 - transistor (PNP) User Manual

Page 22: 7maintenance and fault rectification

7

Maintenance and fault rectification

7

.1 Maintenance

If the instrument is used properly, no special maintenance is required

in normal operation.

7

.2 Remove interferences

The operator of the system is responsible for taking suitable measures

to rectify faults.

VEGASWING

51 offers maximum reliability. Nevertheless, faults can

occur during operation. These may be caused by the following, e.g.:

l

Sensor

l

Process

l

Voltage supply

l

Signal processing

The first measure to be taken is to check the output signal. In many

cases, the causes can be determined this way and the faults rectified.

Should these measures not be successful, please call in urgent cases

the VEGA service hotline under the phone no. +49 1805 858550.

The hotline is available to you 7 days a week round-the-clock. Since

we offer this service world-wide, the support is only available in the

English language. The service is free of charge, only the standard

telephone costs will be charged.

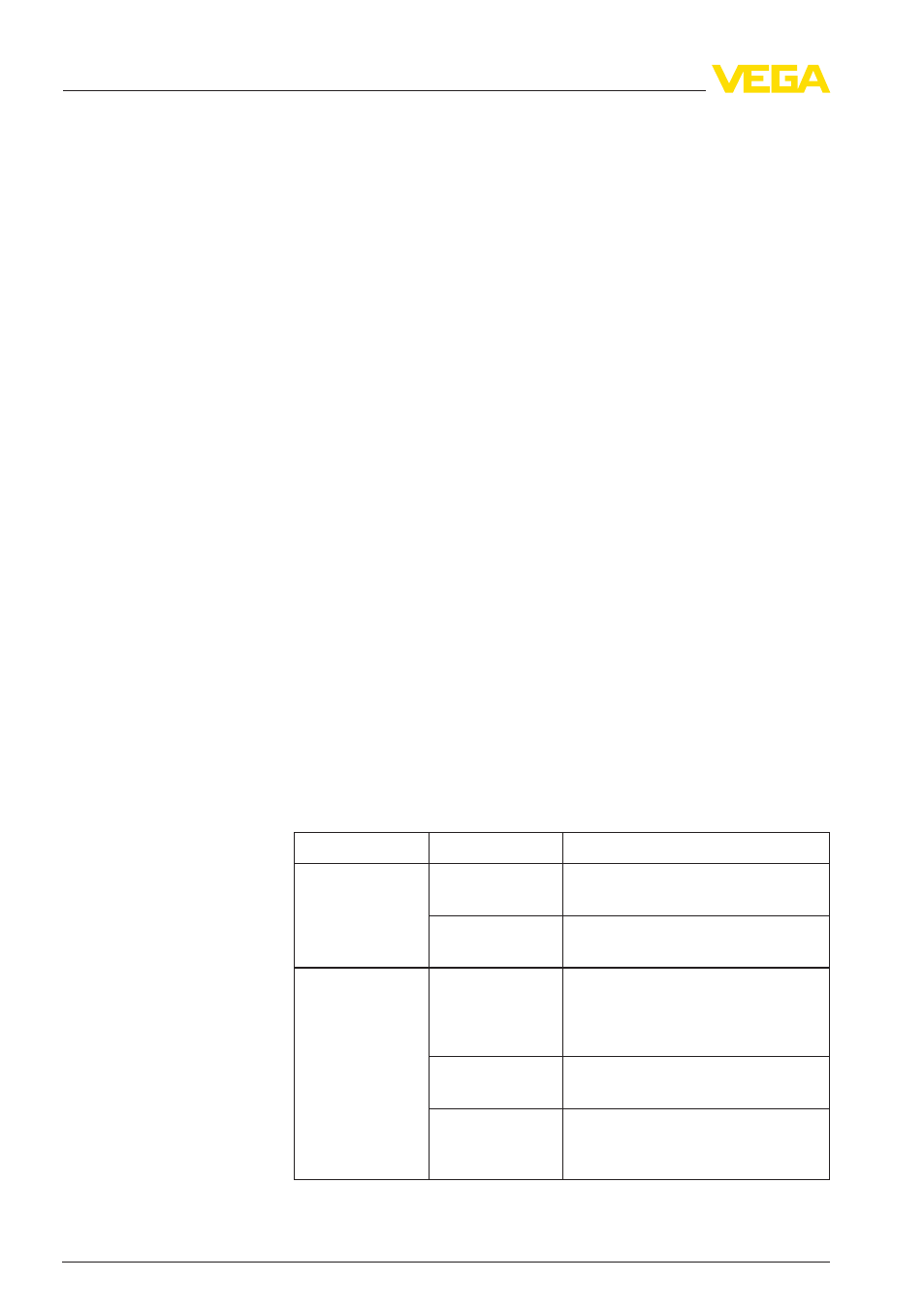

Error

Cause

Rectification

Control lamps off

Voltage supply

interrupted.

Check the voltage supply and the

cable connection

Electronics mo-

dule defective

Exchange the electronics module

Signal lamp fla-

shes red

There was no

load connected

when connecting

to power supply

Connect the instrument correctly.

Make sure that the sensor cannot be

operated without load.

Error on the tu-

ning fork

Check if the tuning fork is damage or

extremely corroded

Buildup on the

vibrating element

Check the vibrating element and the

sensor if there is buildup and remove

it.

Reaction when malfunc-

tions occur

Failure reasons

Fault rectification

24

hour service hotline

Checking the switching

signal

22

VEGASWING

51 • - transistor (PNP)

7 Maintenance and fault rectification

30213

-EN

-120124