3 measurement in standpipe (surge or bypass tube) – VEGA VEGAPULS 41 4 … 20 mA; HART compact sensor User Manual

Page 15

VEGAPULS 41 – 4 … 20 mA

15

26620-EN-041227

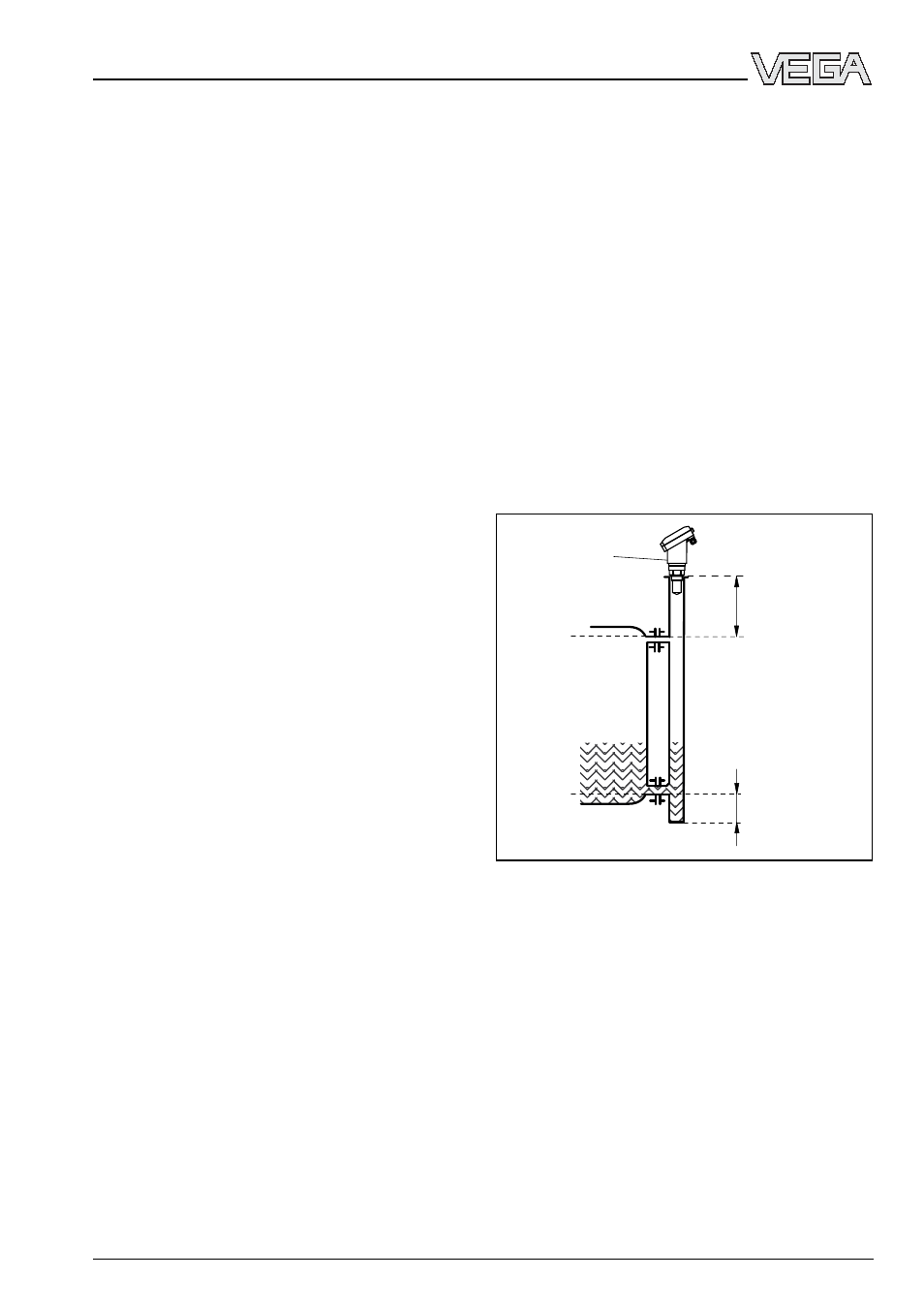

100 %

0 %

> 300 mm

300 ... 800 mm

Tube flange system as bypass tube

Type label

2.3 Measurement in standpipe

(surge or bypass tube)

General instructions

Measurement in a standpipe is preferred in

vessels which contain many installations, e.g.

heating tubes, heat exchangers or fast-run-

ning stirrers. Measurement is then possible

when the product surface is very turbulent,

and vessel installations can cause no false

echoes.

Due to the concentration of the radar signals

within the measuring tube, even products

with small dielectric constants (

ε

r

= 1.6 up to

3) can be reliably measured in surge or by-

pass tubes.

Surge pipes which are open at the bottom

must extend over the full measuring range

(i.e. down to 0% level), as measurement is

only possible within the tube. The tube inner

diameter should be max. 100 mm or corre-

spond to the size of the antenna horn.

Make sure the required upper vent hole in

the surge pipe is aligned with the sensor

type label.

As an alternative to a surge pipe in the ves-

sel, a pipe antenna system outside the ves-

sel in a bypass tube is also possible.

The surge and bypass tubes must generally

be made of metal. For plastic tubes, a

closed, conductive jacket is always required.

When using a metal tube with plastic inner

coating, make sure that the thickness of the

coating is minimal (approx. 2 … 4 mm).

Align the sensor such that the type label lies

on one axis with the tube holes or the tube

connection openings. The polarisation of the

radar signals enables a considerably stabler

measurement with this alignment.

Mounting and installation

When mounting a VEGAPULS 41 sensor on a

bypass tube (e.g. on a previous floating or

displacer unit), the radar sensor should be

placed approx. 300 mm or more from the

max. level.

For products with small dielectric constants

(< 4), the bypass tube should have a length

greater than would normally be required for

the lower tube connection. Products with

small dielectric constants are partly pen-

etrated by the radar signals, allowing the

tube bottom to produce a stronger echo than

the product (when the bypass tube is nearly

empty). By extending the tube downward,

some liquid remains at the bottom even when

the vessel is completely empty.

If enough liquid (300 … 800 mm) remains in

the blind lower end of the tube, the portion of

the signal that penetrates the liquid and re-

flects from the tube bottom is sufficiently

damped - the sensor can then easily distin-

guish it from the echo of the liquid surface. In

cases where there is not enough liquid at the

bottom of the tube, a deflector situated there

will carry out the same function. It deflects

signals that reach the tube bottom into the

standard connection opening.