Innovation down to the smallest detail – Wiha Tools Inomic brochure User Manual

Page 6

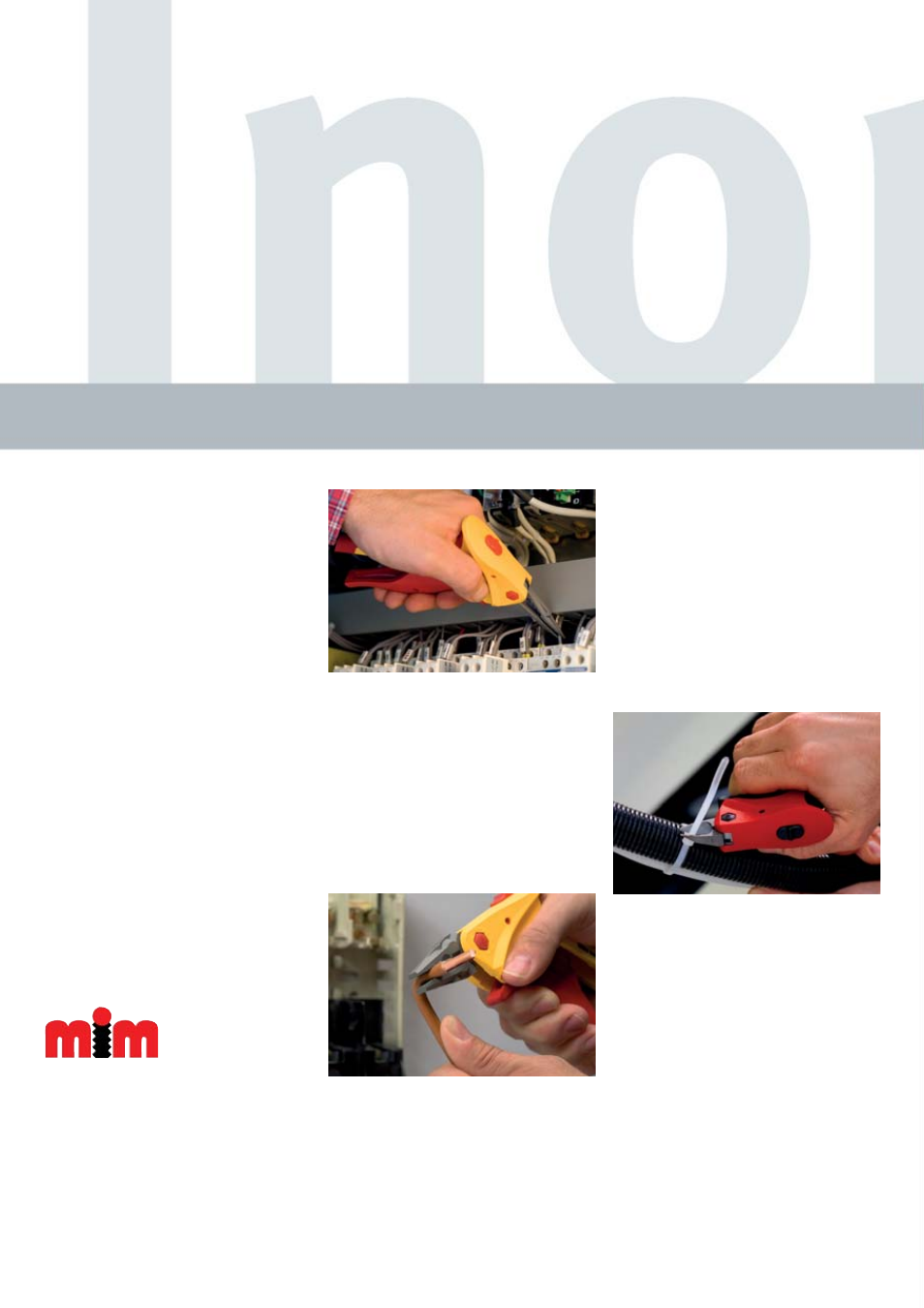

Built for the most demanding use in the

everyday work of professionals.

Wiha Inomic

®

is innovation plus ergonomics

and more. As a manufacturer of premium

tools for professionals, Wiha ensures

uncompromising quality, maximum

reliability and safe design.

Inomic

®

pliers have already passed the

practical test in harsh everyday work.

Whia's leading know-how is behind every

single detail.

Innovation down to the

smallest detail.

Light and precise

The rugged pliers jaws made of

ballbearing steel are produced with the

innovative metal injection moulding

process (MIM). That makes them lighter

and more rugged than cast or forged steel

parts.

A pair of Inomic

®

pliers is up to 20

percent lighter than conventional tools.

Corrosion and maintenance-free

A complete zinc-nickel coating, a develop-

ment from the automotive industry, gives

the pliers jaws permanent, all-round

corrosion resistantance. Hybrid high-tech

produces the joint: Special plastic with

better sliding properties than steel is cast

completely free of play with the plier jaws.

Impact resistant and safe

The ergonomically formed, impact

resistant body of the tool is made of

glass-fibre reinforced plastic, which is

low-friction in the sliding area of the

movable blade and has a soft plastic

coating (thermoplastic elastomer) in the

pressure zone for the ball of the hand.

The opening spring supports controlled,

careful gripping. The catch at the back of

the pliers locks the pliers for transport.

So much safety in a single hand.

MIM

Metal Injection Moulding (MIM) is a

revolutionary moulding process for

manufacturing complexly formed metal

miniature parts with outstanding features

with regard to stability and surface finish.